This is how a variable intake for an aircraft engine works

The cooperation project with BTU is one of the four student projects at Steenbeck-Gymnasium taking part in the "Jugend forscht" competition

Stefan Kazula, who completed his master's degree in mechanical engineering at the BTU Cottbus-Senftenberg, planned to build a demonstrator to better visualize how a variable engine inlet works. Once a student at the Max Steenbeck Gymnasium, he came into contact with the current senior school coordinator, Dr. Torsten Skorubski on the seminar course. In this relatively new school subject, students should learn how to work scientifically. Stefan Kazula remembers: »When I was at school, there was close cooperation between the university and our high school, especially in the MINT subjects; Mathematics, computer science, natural sciences and technology. Through this cooperation, I learned a lot back then and gained experience that helped me a lot in my choice of subject and university. That's how I came up with the idea of developing and building a demonstrator together with the students.«

High School Coordinator Dr. Torsten Skorubski and school director Andreas Käßner didn't have to think long before agreeing, because the cooperation project "Prototype construction of a variable inlet for civil aircraft engines" sounded promising: As part of this project, the students, under the guidance of Stefan Kazula, dealt with scientific research and concept development and acquired skills in dealing with CAD programs and 3D printing technology. They also designed and programmed a control and drive system and developed the associated circuitry. The result was their working demonstrator that they could be proud of. To do this, they worked intensively for two hours a week at the BTU or at the school. The sponsorship association of the Max-Steenbeck-Gymnasium supports the project financially with 1,700 euros.

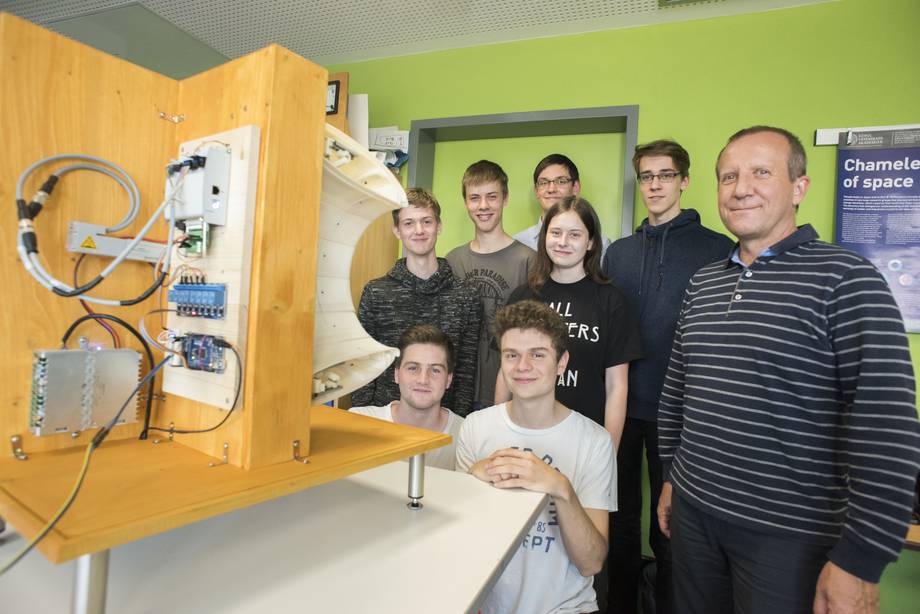

Already in July 2017, after only one school year, the project team had a result that is impressive! The prototype is assembled and the desired contour can be set using the electrical control. Thomas Döding, Max Theuner, Martin Selleng, Tillmann Heilmeyer, Antonia Mühlberg, Eloy Schröter and Tim Pokart are proud of it. Stefan Kazula describes it like this: »It is impressive how the students have developed during the project work and how much effort they have put into their free time. When you see how the prototype moves, you can hardly imagine how difficult and instructive it was for all of us to get there!" And he adds with a smile: "At the beginning we all had to get to know each other and our tasks find in the group to fulfill the established schedule. So our weekly meetings sometimes resembled a wild mess. But that's exactly how I learned a lot about leading project groups, and the preliminary result also shows how much the students have learned in the time, so that the learning effect as well as the pride and joy about what we have achieved together is shared by all of us prevails.«

In his research, Stefan Kazula, academic assistant at the Chair of Flight Engine Design with Prof. Dr.-Ing. Klaus Höschler, design options for improving aircraft engines. The specific aim is to find innovative and yet feasible concepts for variable engine inlets in civil aviation. The engine intake has the essential task of supplying the engine with air without any problems, particularly during aircraft take-off, and at the same time generating as little air resistance as possible during fast cruising. An uninterrupted inflow to the rest of the engine can be ensured by a wide inlet contour with large radii. On the other hand, a low air resistance is achieved through an inlet geometry that is as narrow and sharp-edged as possible. In modern engines, these conflicting contour requirements are met only by compromise. By using a variable intake geometry, as studied by Stefan Kazula, future aircraft could have a larger operating range and fly more efficiently or faster.

Technology has always fascinated the young mechanical engineer, so he began studying at the BTU in 2010 after graduating from high school. Since 2013 he has been a student assistant at the chair of Prof. Dr.-Ing. Klaus Hoeschler. Since then, the professor has known Stefan Kazula's reliable and conscientious approach and supports him in his plan to involve students in the construction of the demonstrator.