Innovative Production Methods

Accurate joining of two different materials and sheet thicknesses

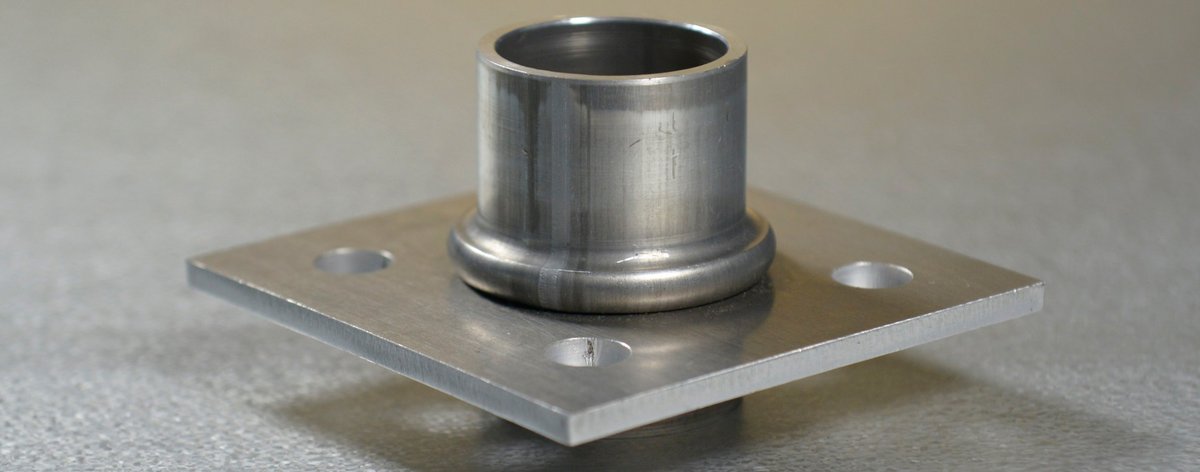

The reliance on higher-strength materials poses great challenges for joining technologies in the automotive business and other industries. The combination of different materials and sheet thicknesses is becoming ever more important. Established thermal joining methods such as welding quickly come up against their limitations here. The consequences can include a loss of stability, greater tendency to warp, and vulnerability to cracking. Where pipes or profiles need to be joined with metal sheets, upset bulging can offer an alternative as a forming-based joining method. The process enables a cost- and resource-efficient manufacture of products.

The scientists around Prof. Dr.-Ing. Markus Bambach, Chair of Mechanical Design and Manufacturing, are developing these mechanical joining processes where parts are joined by three-dimensional forming, rather than the local fusing of two materials. "This process can help to reduce cycle times, automate joining operations and increase the accuracy at the joint", says Bambach.

A project successfully concluded in 2014 has provided the researchers with extensive findings about the fundamental process of upset joining at room temperature. The project that built on this, which has now been concluded, was focussed on a further process optimization and the application of heat before the forming. "We were able to demonstrate that heating the part in the area that is to be deformed enables a better result while reducing the effort required. Short-term local heat application can similarly provide pipes with pre-defined kink points, which further increases the flexibility of this joining process", comments research associate Michael Rusch. The scientists are realizing the heating of the pipes to up to 700 degrees Celsius by way of a non-contact inductive heating system of their own devising that is highly efficient.

The scientists primarily devoted themselves to experimental studies. A computer-aided simulation of the process, which can for example serve to predict process parameters, could be realized in cooperation with the Institute for Forming Technologies and Machines (IFUM) at Hannover University. A recently started follow-up project is dedicated to increasing the bond strength and expanding the application range of upset joining from May 2016 to April 2018.

The project with the title "Process optimization of upset joining by local warm forming" was funded and overseen by EFB, the European Research Association for Sheet Metal Processing. The two-year project was supported by the German Federation of Industrial Research Associations (AiF) as part of the Promotion Programme for Cooperative Industrial Research (IGF) run by the Federal Ministry for Economic Affairs and Energy.