Evaluating Sensitivity to Thermal Shock

In the framework of the DFG priority programme 'Refractories − Initiative to Reduce Emissions − FIRE', the Chair of Joining and Welding Technology lead by Prof. Dr.-Ing. Vesselin Michailov, is developing a complex evaluation method for thermal shock sensitivity of refractory ceramics. The focus is on experimental and numerical investigations of thermal shock behaviour, taking into account the conditions of use, material behaviour and component geometry. The aim is to significantly reduce carbon dioxide emissions worldwide through low-carbon refractories and to save energy by way of improved thermal insulation.

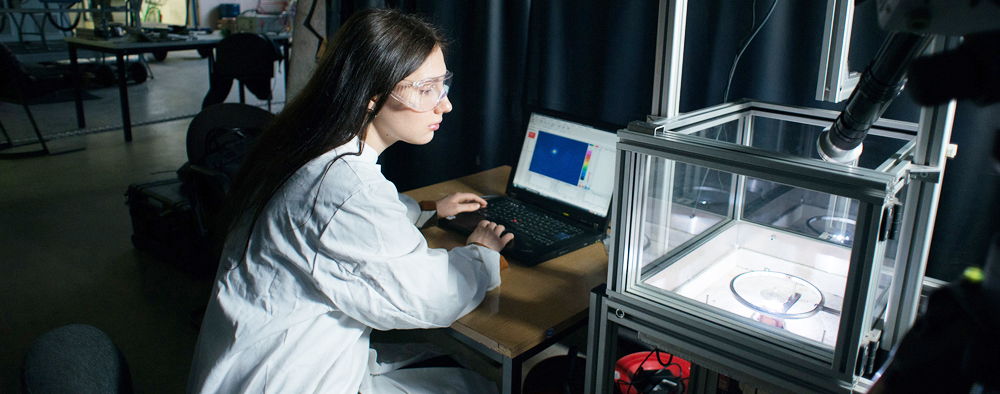

The project team have devised and tested a two-stage evaluation process for the further development of components made of refractory ceramics. In the first stage, using the extended simulation and test center Gleeble 3500, the thermomechanical properties of laboratory samples from various refractory materials prepared by the SPP project partners were determined. Thermal shock behaviour of ceramic disk samples were investigated by using the developed plasma beam test stand. Furthermore, finite element (FE) simulation was carried out to calculate the temperature and stress distribution within the ceramic disks, and critical stresses and failure criteria were determined.

It was found that determining the exact location of the crack initiation is decisive in identifying the failure criterion. In order to localize the point of failure under thermal shock, Prof. Dr.-Ing. Vesselin Michailov’s research group is working on further refining thermal shock testing for notched specimens. To determine the failure criterion, the team is processing the coupled thermo-mechanical finite element simulation for 3D models with notches. The advanced prediction method will be tested on at least one demonstrator component in the second stage. The failure of the components is simulated using the established criteria with the FE method and validated by experiments.

The partners on the project are: