Oxyfuels – energy solutions in hard-to-electrify sectors

The background to Rufat's work in the Energy and Conversion (ESC) Lab at the Cottbus Energy Innovation Centre is the increasing demand for carbon-neutral energy solutions and specifically for power-to-X-to-power systems. In such systems, synthetic methane is produced from green hydrogen and captured CO2 and converted into electricity and heat without emitting CO2 into the atmosphere.

In his study, Rufat provides an insight into the combustion characteristics of oxy-methane combustion in a single-cylinder petrol engine. In particular, the influence of different dilution quantities and compositions of oxygen, carbon dioxide and water on the cylinder pressure, cylinder temperature, heat release and burnt mass fraction as well as on the concentrations of carbon monoxide, carbon dioxide, hydrogen and methane during the working cycle is investigated.

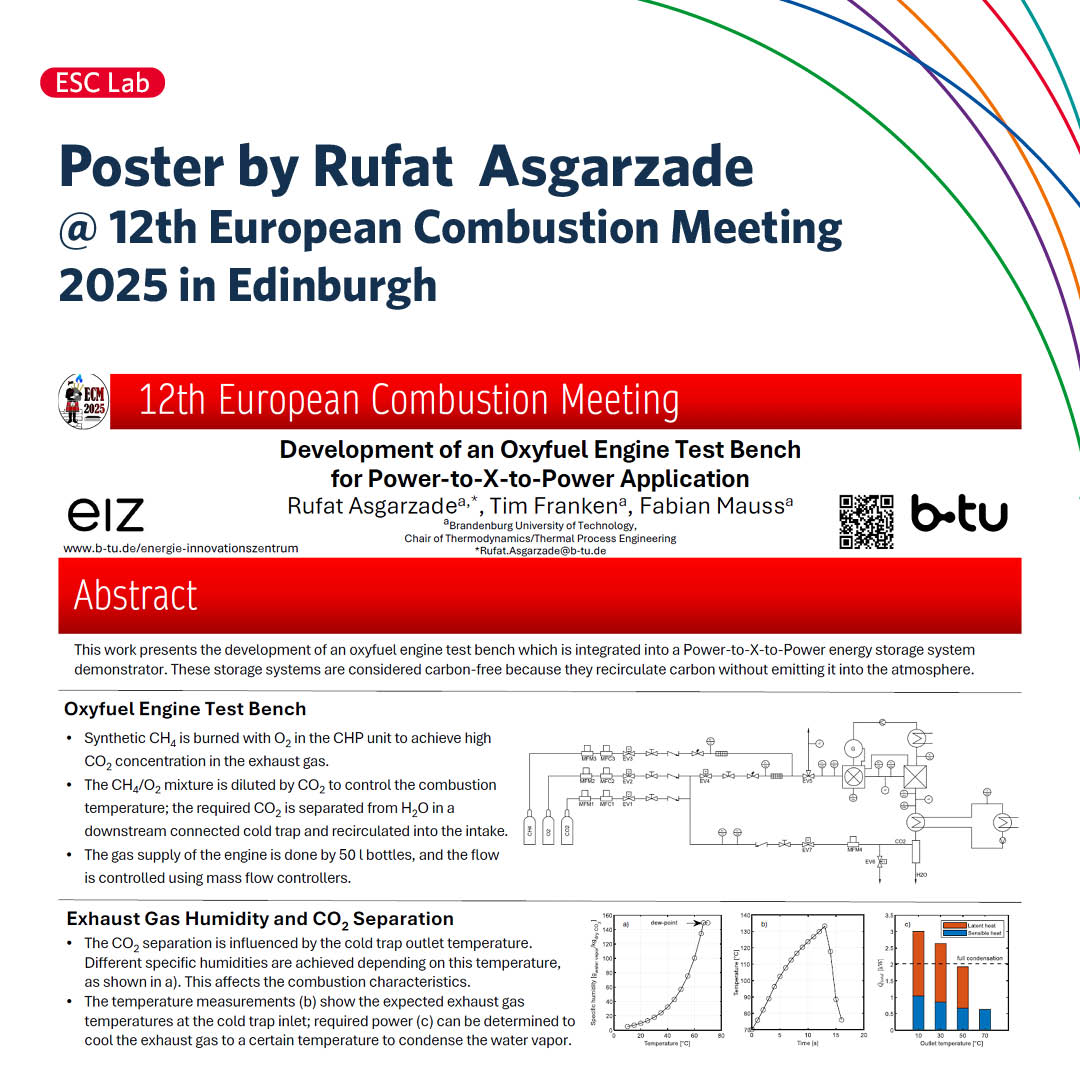

A Power-to-X-to-Power (P2X2P) energy system demonstrator is currently being developed at the Brandenburg University of Technology (BTU) Cottbus-Senftenberg to realise NOx-free heat and power generation in a CO2-neutral closed cycle. In the Sabatier reactor, synthetic methane is produced from green hydrogen and captured CO2, while green hydrogen is produced by electrolysis of water. The electricity is mainly supplied by renewable energy sources.

The conversion of synthetic methane into electricity through the oxyfuel combustion process closes the cycle and enables the capture and storage of CO2 for subsequent methane synthesis. In the oxyfuel engine, the CH4/O2 mixture is diluted with CO2 to control the combustion temperature. The required CO2 is separated from the water in the exhaust gas in a downstream cold trap and returned to the gas mixing station, where it is mixed with methane and oxygen.

The results show that a CH4/O2/CO2 mixture, when introduced into the engine together with water vapour, changes the combustion characteristics compared to conventional air operation. While CO2 dilution lowers the peak pressure and temperature in the cylinder, increasing the proportion of water vapour in the same dilution volume funds faster flame propagation and reduces emissions of unburned components. A significant reduction in cooling capacity was also achieved. These results will subsequently be investigated on the engine test bench at BTU and will make an important contribution to the research, broad utilisation and commercialisation of oxyfuels - low-carbon energy solutions for the decarbonisation of sectors that are difficult to electrify.

The aim of the Energy and Conversion (ESC) Lab is to map the four levels of sector-coupled energy systems – heat, electricity, storage and mobility – in a CO2-neutral cycle approach based on green hydrogen.

Contact us

Thermodynamik/Thermische Verfahrenstechnik

ScienceComm@EIZ

Regelungssysteme und Netzleittechnik

T +49 (0) 355 69-4953

kathrin.schluessler(at)b-tu.de