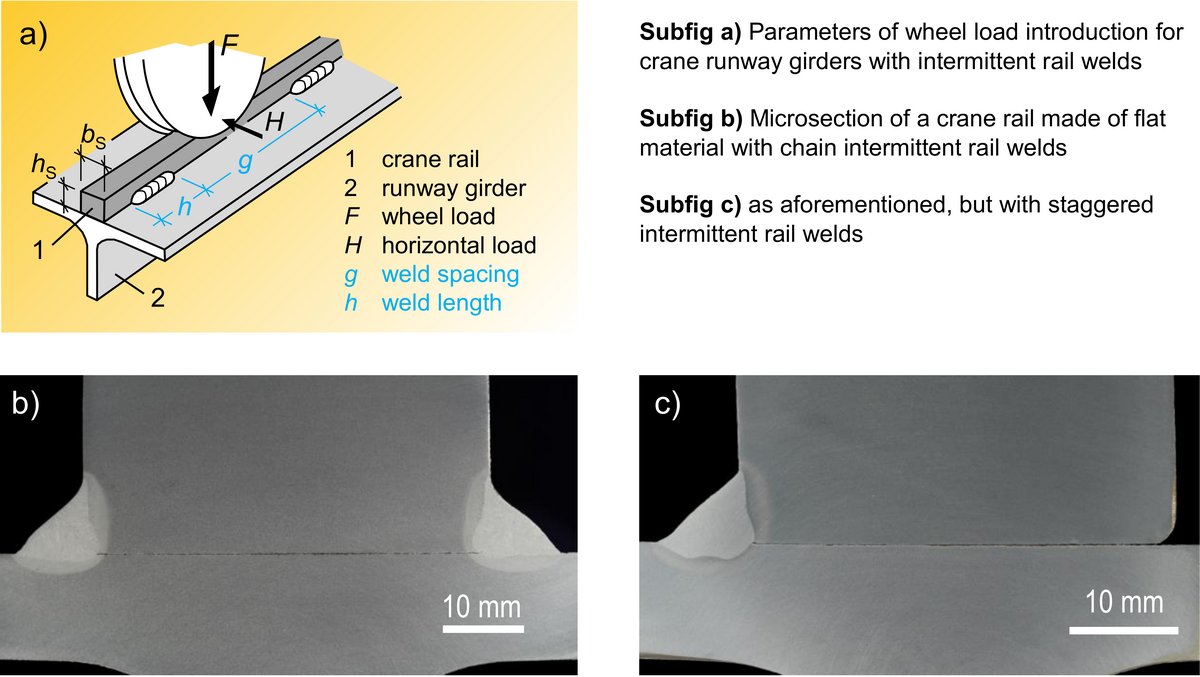

Economical and resource-saving crane rail fastening by means of intermittent welds

Fastening flat and square rails to crane runway girders by means of intermittent rail welds has been a common construction method for light to medium-duty crane operation for many decades. By avoiding continuous rail welds, the production time and material usage are reduced on the one hand, and on the other hand the welding distortion of the crane runway girder and thus the subsequent straightening effort is reduced. Due to the repeated loading caused by the crane's wheel loads, the rail welds are generally at risk of fatigue. To date, however, the fatigue verification of intermittent rail welds has not been regulated in accordance with Eurocode 3. For chain intermittent rail welds with a weld length of 50 mm, there is already a design proposal from a completed IGF research project, albeit with a limited scope of application. This proposal has already been incorporated into the Eurocode draft standard prEN 1993-6. The scope of application of this design proposal is to be significantly extended by the current research project for a staggered intermittent rail welds and for longer welds (> 50 mm) with a chain arrangement in order to reflect the full range of production in practice.

Funding organisation: Federal Ministry of Economic Affairs and Climate Action (BMWK)

Funding programme: Industrielle Gemeinschaftsforschung (IGF)

Funding reference: 01|F23275N

Duration: 01.05.2024 - 30.04.2026