Compact AI-based hyperspectral camera opens up new industrial applications

The aim is to integrate hyperspectral analyses directly into production, sorting and diagnostic processes - quickly, energy-efficiently and practically.

Targeted analysis instead of a flood of data

The technological core of the system lies in a novel measurement approach: instead of analysing complete images hyperspectrally, a conventional 2D camera first captures the object. An AI then identifies relevant image areas(regions of interest) where targeted spectral measurements are carried out, significantly reducing the amount of data, energy consumption and computational effort while retaining the crucial chemical information.

This is what it's all about in detail

Sub-project A1 is dedicated to the development of an ultra-compact, energy-efficient hyperspectral camera that enables complex material and quality analyses in real time thanks to artificial intelligence. The integrated spectrometer captures spectral characteristics and thus visualises chemical properties that remain hidden to the human eye. Defects in food or the composition of textiles or plastics can thus be identified precisely and quickly.

The innovative hyperspectral camera opens up numerous fields of application along industrial and agricultural value chains. The camera works according to an innovative principle: a conventional 2D camera first captures a high-resolution image of the object. Artificial intelligence analyses this image in real time and automatically identifies the areas of interest, the so-called regions of interest. The integrated spectrometer only carries out a spectral analysis at these selected positions and determines the chemical composition. This intelligent approach makes hyperspectral measurements significantly more efficient: Instead of laboriously capturing the entire image hyperspectrally, only the relevant measuring points are analysed. This significantly reduces data volumes, energy consumption and computing time.

The resulting information supports the reliable sorting of textiles and plastics, for example, and increases reliability in the identification of counterfeits. They also improve quality control in food processing by detecting bruises and defects, and enable precise assessment of plant condition and nutrient requirements in agriculture. Automated evaluation means that decisions can be made much more quickly and reliably. At the same time, processes are made more sustainable and economic resources are utilised more efficiently.

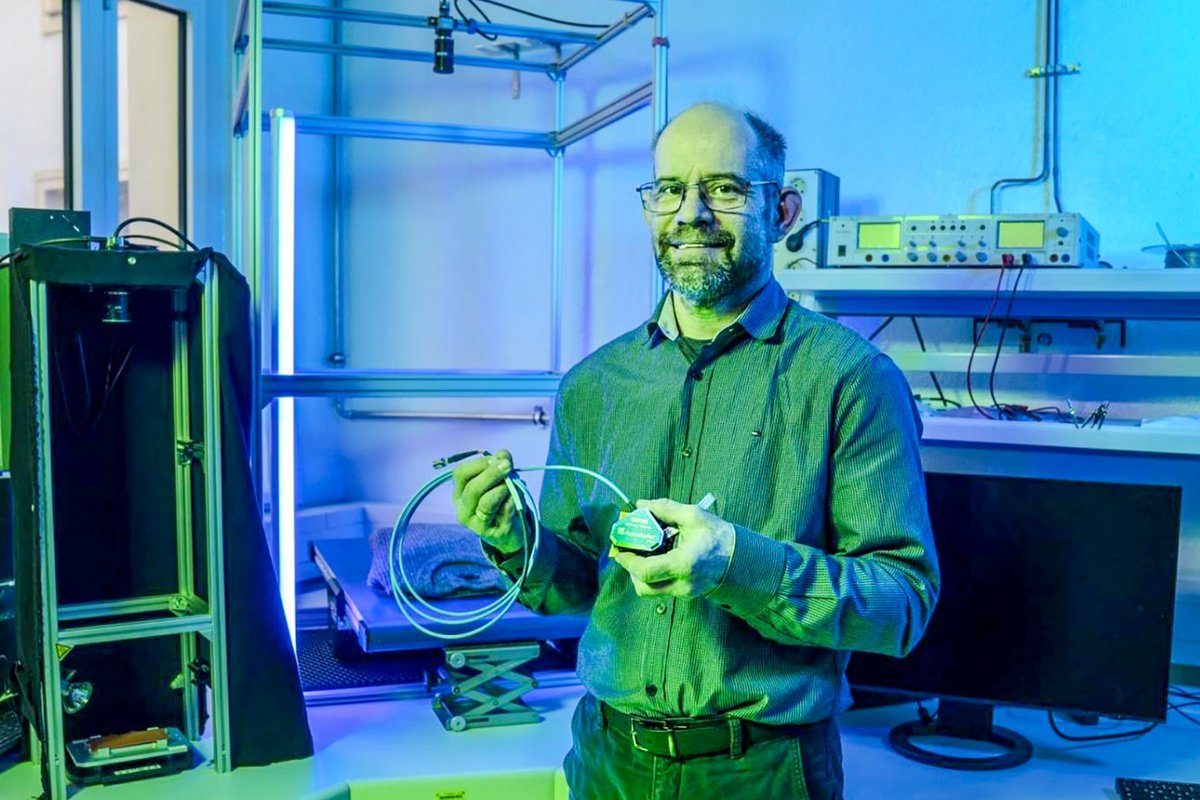

"With the compact hyperspectral camera from OASYS A1, we are creating a technology that brings analytical processes to where they are needed: directly into production lines, sorting systems or onto the field," explains Heinrich Engelke, project manager at the Fraunhofer Institute for Photonic Microsystems IPMS. "The combination of miniaturisation, energy efficiency and artificial intelligence opens up completely new application possibilities and at the same time makes an important contribution to resource conservation and process reliability."

The components developed in the project form the basis for future sensory systems that can achieve significant improvements in industry and recycling as well as in the agricultural and food sectors.

About the project

The OASYS research programme covers a period of five years from September 2023 to August 2028 and is funded by the Federal Ministry of Research, Technology and Space (BMFTR) with around 12.5 million euros. The Brandenburg University of Technology Cottbus-Senftenberg (BTU) is coordinating the project. In addition to the Fraunhofer IPMS, the Ferdinand-Braun-Institut FBH and the IHP - Leibniz-Institute for Innovations for High Performance Electronics are also involved in the network. The joint commitment in OASYS and in particular the work in project A1 emphasise the leading role of Fraunhofer IPMS in the development of innovative optical system technologies.

Further information about the OASYS project and the partners is available on the website https://oasys-cottbus.com.