Wire-Arc Additive Manufacturing

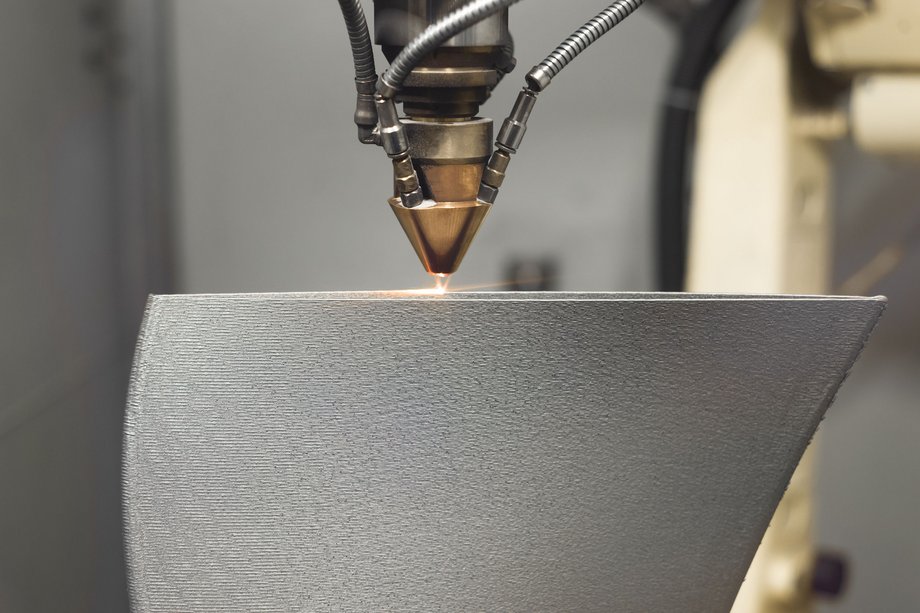

The production method Wire-Arc Additive Manufacturing (WAAM) belongs to the additive manufacturing techniques, which find wide application in the industry for the material-efficient production of weight-efficient workpieces. In WAAM, a wire is molten by a movable welding head and deposited in droplets on a substrate plate to build the workpiece layer-wise. During the process, the occurring temperature gradients within the workpiece and the chosen path of the welding head significantly affect the quality of the created product. Thus, it is desirable to choose a path that creates a preferably homogenous temperature distribution within the workpiece and differs from the one used in the previous layer at the same time. These criteria help to reduce strain within the material and increase the stability of the product.

BTU-Partners

Prof. Markus Bambach, Chair of Mechanical Design and Manufacturing

Prof. Michael Breuß, Chair of Applied Mathematics

Related talks

- Temperature Based Trajectory Optimization for Wire-Arc Additive Manufacturing, 8. TOR Workshop, Siegen, 09.03.2021.

- Temperature Based Trajectory Optimization for Wire-Arc Additive Manufacturing, SIGOPT 2020, Dortmund, 04.03.2020.

- Temperature Based Trajectory Optimization for Wire-Arc Additive Manufacturing, WSOPT 2019, Olbernhau, 14.03.2019.

Related publications

- Martin Bähr, Johannes Buhl, Georg Radow, Johannes Schmidt, Markus Bambach, Michael Breuß, Armin Fügenschuh, Stable honeycomb structures and temperature based trajectory optimization for wire-arc additive manufacturing, Optimization and Engineering, Vol. 22, Issue 2, pp. 913-974, 2021.

- Armin Fügenschuh, Markus Bambach, Johannes Buhl, Trajectory optimization for wire-arc additive manufacturing, Operations Research Proceedings 2018. Springer, Cham, pp. 331-337, 2019.