Versatile Factories stay Competitive

A project in the Faculty for Factory Planning and Operation is developing strategies for the competitiveness of enterprises in the Lausitz region

The globalization of production processes, growing market dynamics and increasing cost pressure are forcing companies into a constant innovative adaptation of their factory and production structures to the changed framework conditions. While many large companies plan and adapt their factories in own, specialized departments, this is often hardly feasible for SMEs in financial and structural terms. Prof. Dr.-Ing. Peggy Näser and her team want to change this and support regional companies in the Lausitz in the structural change.

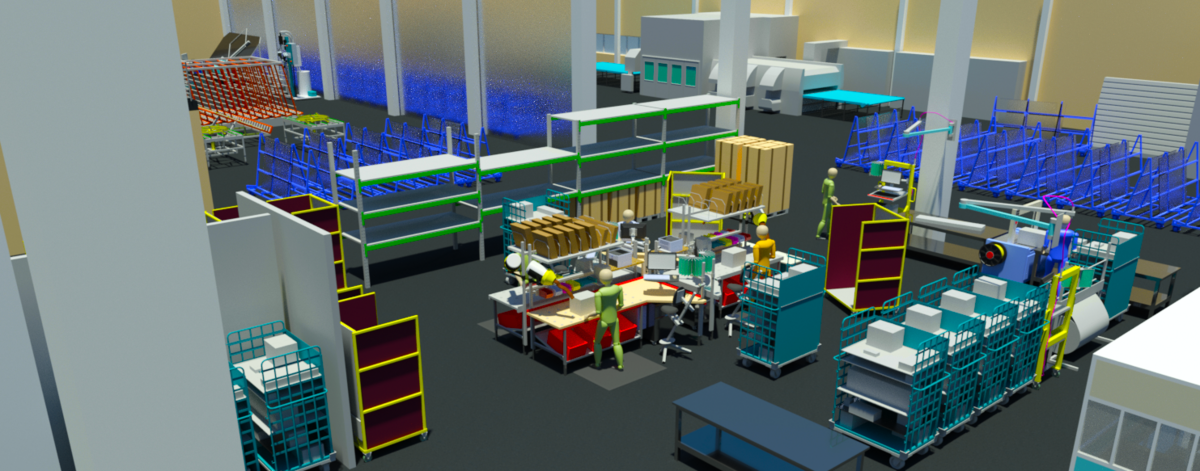

In their latest project, the scientists from the Faculty for Factory Planning and Operation are developing a strategic concept for a M+R Filtermedien GmbH factory in cooperation with the Institute for Environmental Technology and Recycling Senftenberg and the engineering firm fabrik-ID. Growing lot sizes, new products, technologies and production processes need to be realized at a new location. The ability to work flexibly is essential for the company to quickly respond to the constantly changing customer requirements. The company furthermore wants to digitalize the processes in parallel with its relocation within Wandlitz. The basis for this is a new concept that adapts the material and information flow in the transport, storage and pre-packaging of the products, but also the workplaces for the personnel, in a corresponding manner. "This is a tremendous challenge because various disciplines need to be involved", says Näser. "The planning of versatile factories calls for interdisciplinary teams comprising process and logistical planners, architects, building services and systems engineering experts. Also required in addition to this is internal and external know-how in the areas of corporate strategy, law, marketing and environmental protection."

The software provided in the faculty enables an optimal planning of the production process and simulation of its workflows by the researchers. "Especially for small and medium-sized enterprises, looking at a factory or individual production line on a screen first is important. It helps to assess the producibility of new products, and can be used to plan, simulate and evaluate automatic or manual manufacturing systems. So far it has mostly been large companies who plan their series manufacturing digitally, primarily in the automotive and aircraft industry. We are aiming to also support the smaller companies in Brandenburg with our know-how."

The project with the title "Strategic design of processes and layout for a new company location in consideration of an increasing digitalization" is funded by the Federal Ministry for Economic Affairs and Energy with 15,000 euros for a three-month period as part of its Central SME Innovation Programme.