For more sustainable aviation in the future

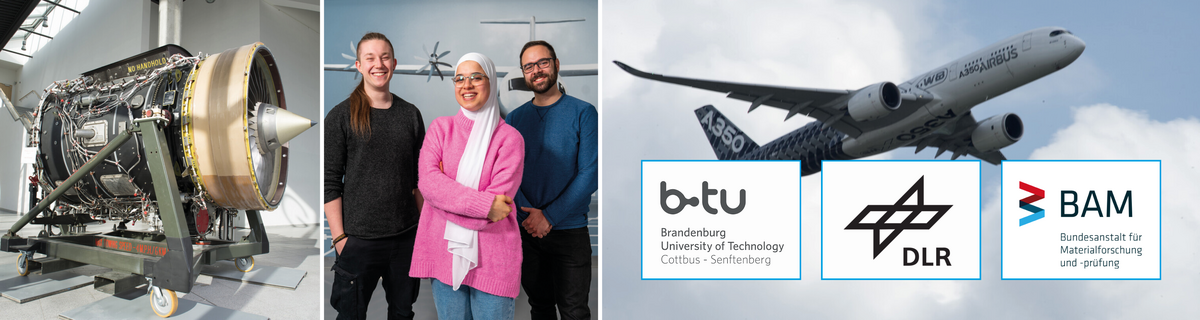

[ˈskai]-lab - Quality control, structural health monitoring and operational safety of additively manufactured components for electrified aircraft engines

The BTU-DLR-BAM cooperation ['skai]-lab set up by BTU Cottbus-Senftenberg, the German Aerospace Center (DLR) and the Federal Institute for Materials Research and Testing (BAM) combines the various areas of expertise in additive manufacturing (BAM, BTU) and non-destructive testing / structural health monitoring (BAM) with the application requirements for novel propulsion concepts and components in aviation (DLR) and thus makes an important scientific contribution to sustainable aviation. The combination of the different expertise of DLR, BTU and BAM offers great added value here, as the research focuses complement each other in a unique way. In addition, ['skai]-lab enables the transfer of scientific expertise, including the energy sector, to the aviation industry.

It is the aim of [‘skai]-lab to train the next generation of interdisciplinary aviation and manufacturing scientists. Working in science, industry and the public sector, the graduates will be well-equipped to play a groundbreaking role in the further development of the aviation economy.

At the heart of the cooperation is a unique aviation-focused qualification programme that provides all PhD candidates with a holistic understanding of the manufacturing value chain, quality control measures and methods, and the regulatory framework. A wide range of soft skills courses and summer schools also optimally prepare PhD candidates for their future careers in terms of their personal skills.

['skai]-lab is embedded in the large international network of DLR, BAM and BTU, which enables PhD candidates to undertake (inter)national research stays in industry, science and the public sector.