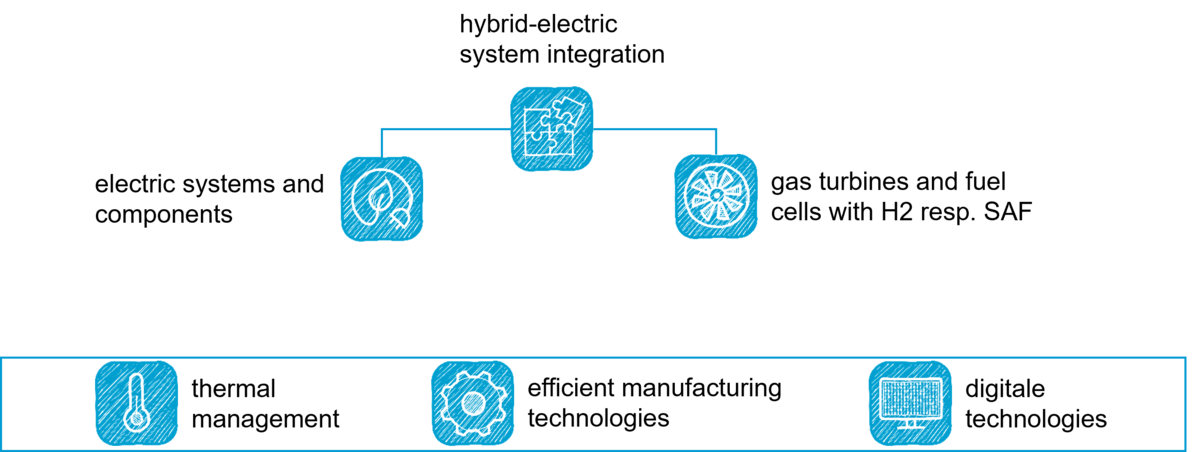

Our Fields of Research

Hybrid-electric system integration

In hybrid-electric drive systems, electric drives are combined with additional energy converters, with the required energy being carried in an electric storage unit (battery) on the one hand and in an additional storage medium on the other, which can be designed differently depending on the application. Internal combustion engines powered by fossil or non-fossil fuels are often used as the second energy converter. Fuel cells are also conceivable for generating electrical energy, for example from hydrogen. Both are currently being developed for aviation, maritime and land transport. Hybrid electric drives also include e-bikes, where human muscle power supplements the battery-powered electric drive. In the rail sector, battery-powered multiple units are sometimes referred to as a special case of hybrid-electric Systems. On non-electrified sections, these trains run in battery mode, and on electrified lines in overhead line mode. The coordinated combination of different energy sources and drive systems, with their respective strengths and weaknesses, into a single overall system is the task of hybrid-electric system integration. The main objective is to increase the efficiency of the overall system and reduce energy consumption, weight and emissions.

Electrical Systems and Components

The electrical systems and components cover the electrical side of hybrid-electric drives.

They include basic building blocks of modern Electrical Engineering, such as motors, generators, power electronics, and electrical storage (batteries). In the electrical system, they enable electrical energy to be stored, transmitted, controlled, converted, and used. Only they enable the functionality of electrically driven devices, machines and vehicles. At chesco, electrical component and system technologies are developed and continuously improved. They thus offer extended application possibilities as innovative answers to today's technological challenges.

Gas turbines and fuel cells

Gas turbines and fuel cells are energy conversion technologies that cover a wide range of applications from power generation to Propulsion Technology. At chesco, they are of particular importance in the development of hybrid-electric drive systems.

Gas turbines are thermal machines that heat air by burning fuel, increasingly hydrogen or Sustainable Aviation Fuels (SAF) in the future, to produce a continuous gas flow that drives the actual turbine. They draw in air, compress it, heat it by burning fuel, and then drive the expanding exhaust gases through a turbine, which in turn drives the compressor and, in an aircraft engine, often the fan or propeller to generate the necessary thrust and propel the aircraft forward. Gas turbines are capable of starting up relatively quickly and are highly efficient at converting fuel to electrical energy or thrust.

Fuel cells are devices that convert a fuel (usually hydrogen) and an oxidant (usually oxygen from the air) into electrical energy and heat in an electrochemical reaction, where the electrical current can be used directly and water is produced. The process occurs at a lower temperature than combustion. Fuel cells offer high efficiencies, low emissions, and low noise levels. Hydrogen fuel cells can serve as a quiet, low-emission, and highly efficient power source that generates electrical energy for electric engine propellers or fans. This is expected to contribute to quiet and environmentally friendly flight operations with reduced emissions of carbon dioxide and pollutants.

Hybrid-electric propulsion concepts often integrate both gas turbines and fuel cells, allowing the benefits of both technologies to be combined, improving efficiency and range, while minimizing environmental impact.

Cross-cutting technologies

Thermal Management

Thermal management refers to the discipline and techniques used to efficiently control and regulate temperature in electrical devices, Systems or processes. Currently, electrical machines and electronics are becoming more and more compact and powerful. Effective thermal management is therefore becoming increasingly important to ensure a safe and reliable operating environment. At chesco, innovative solutions are being developed to ensure the safety of electrical components and systems.

The task of thermal management is to efficiently dissipate heat that is generated in order to prevent overheating, but also to ensure a minimum temperature and thus, for example, the functionality of battery storage systems. Overheating can impair the performance of electronic components or lead to permanent damage. A distinction is made between active and passive thermal management. Active thermal management describes methods that require energy to dissipate heat, such as fans or ventilators. Passive methods do not require external energy to dissipate heat. An example of this is heat pipes or heat sinks, which dissipate heat with as large a surface area as possible.

Efficient manufacturing technologies

Efficient manufacturing technologies are approaches that aim to optimize production processes to achieve increased productivity, cost savings and quality improvement. They aim to minimize resource consumption and shorten manufacturing times while maximizing product quality. An important goal of chesco is to drastically shorten innovation cycles from design to manufacturing to testing and to allow improved design as quickly as possible. To achieve this, efficient manufacturing technologies are essential.

A key principle of efficient manufacturing technologies is the reduction of waste in the form of time, material and energy. This includes various approaches such as automating processes, integrating Industry 4.0, using additive manufacturing technologies and lean manufacturing. Additive manufacturing creates an environment in which processes must be constantly adapted to new requirements and needs. Work is done in open teams to solve problems more efficiently. Efficient manufacturing technologies play a critical role in increasing competitiveness. The continuous development of these technologies is of great importance in order to meet the constantly changing requirements in modern industry.

Digital technologies

Digital technologies encompass various innovative approaches based on electronic data processing and digital communication. They are already having an impact on how we communicate, how we work, and they determine a large part of information processing. They are driving progress in an increasingly networked and digitized world. Digital technologies include artificial intelligence, for example, as well as Big Data and digital twins. The digital twin creates a virtual image of physical objects or functional processes. It enables environmental influences to be applied to a product in real time. In this way, functionality and product properties can be tested under specific conditions. The use of augmented and virtual reality additionally changes working in virtual environments. A CAVE is available at chesco for this purpose.

By incorporating modern technologies, chesco aims to adapt to the new way of working and digitize everyday work. This creates new opportunities for innovation, increased efficiency and personalized experiences, but also requires careful planning to address potential challenges and take full advantage of these technologies.