Central Scientific Facility of chesco

Objectives and structure of the chesco ZWE

At chesco ZWE, alternative drives are developed, manufactured and tested in order to reduce climate-damaging emissions in the mobility sector. The areas of application are cross-sectoral. However, the first projects will be launched in the aviation sector, as climate-neutral flying poses the greatest technological challenges and requires the most intensive research. The aim of chesco is to extremely accelerate the innovation cycle. Instead of several months, the innovation process should only take a few weeks. To achieve this goal, the design, production and testing departments will be brought together in one place and all processes will be mapped digitally.

Players

The Central Scientific Institution of the Center for Hybrid Electric Systems Cottbus (chesco ZWE) was founded at BTU under the scientific direction of Prof. Dr.-Ing. Klaus Höschler, Prof. Dr.-Ing. Georg Möhlenkamp and the operational management of Dr. Jane Worlitz. The rest of the chesco ZWE team currently comprises almost 50 people who are setting up the chesco research factory in Cottbus Dissenchen and developing a transfer concept for the regional economy.

In addition, three BTU faculties with over 30 specialist areas are involved in chesco ZWE and its projects. The faculties contribute their expertise as members of chesco ZWE in the research fields relating to hybrid-electric system integration.

Funding

The chesco ZWE is being supported with almost 1/4 billion euros from structural strengthening funds (238 million euros Arm I and 18 million euros STARK).

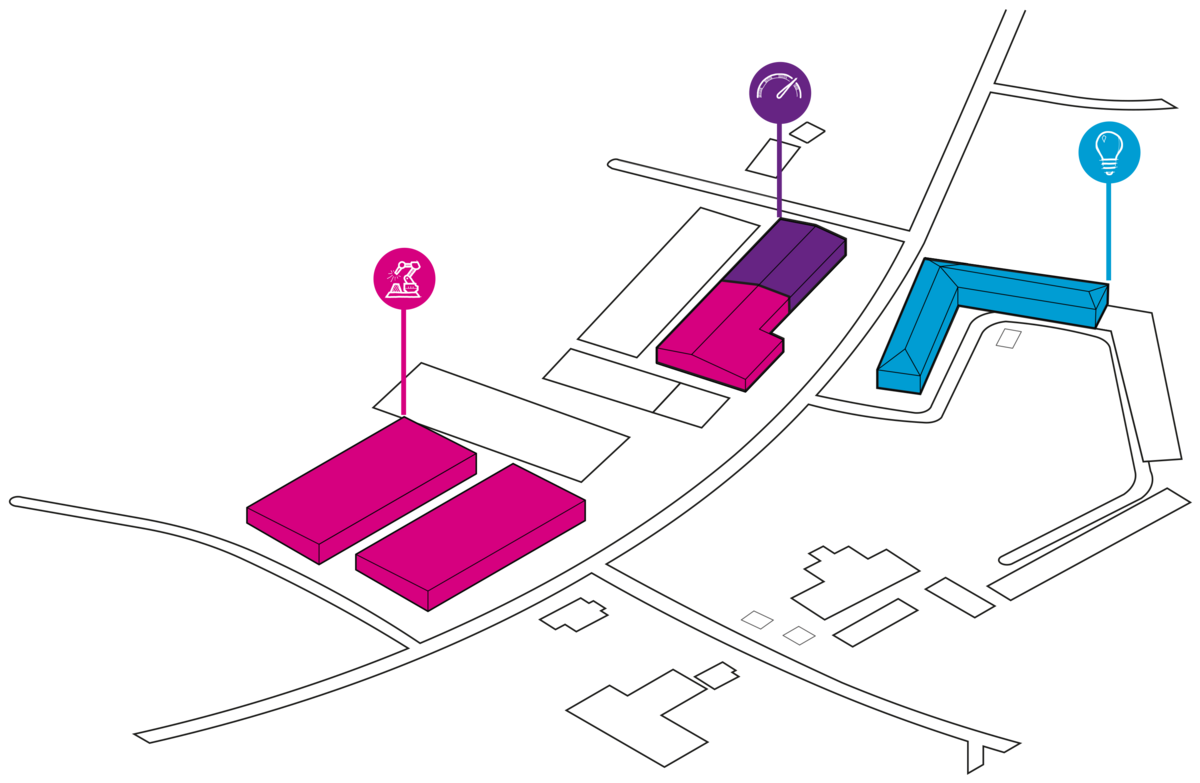

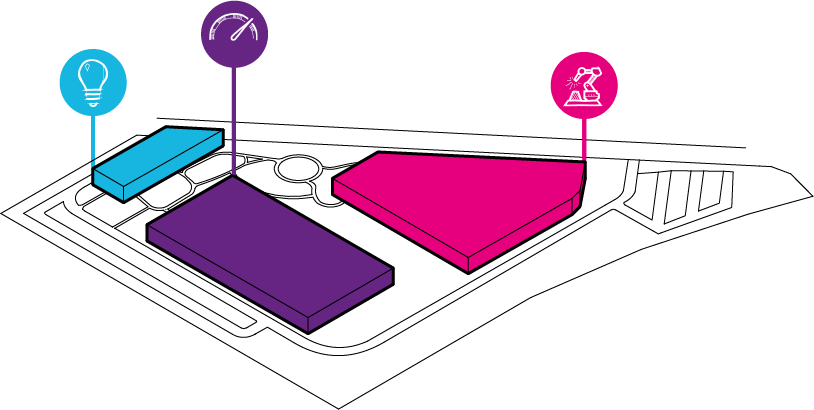

Infrastructure development chesco

The infrastructure of the chesco will be developed with 238 million euros from Arm I. Several functional units are planned: the research center with a multi-space office concept for collaboration on research projects with partners from science and industry, the f-merc with state-of-the-art manufacturing processes for the production of prototypes and the test center with (altitude) test benches for testing the prototypes. All processes will be digitally networked with each other. The Lausitz Science Park (LSP) is being built on the site of the Technology and Innovation Park (TIP site) on the north-western outskirts of Cottbus in the immediate vicinity of the main BTU campus. The new chesco building will be constructed here on approx. 5 hectares.

The "Transfer of agile manufacturing methods" project to strengthen the region (STARK)

The second funding amount of 18 million euros will be used to strengthen the region. This will finance the "Transfer of agile manufacturing methods" project (taf for short).

Innovative and efficient manufacturing techniques are a research focus at chesco. The BTU has been researching these technologies for 30 years. The taf project was initiated to make this bundled knowledge available to regional companies. The project aims to strengthen networking with industry and promote the transfer of knowledge in the field of agile manufacturing methods in the region.

Through agile manufacturing, results can be achieved in a shorter time without economic or qualitative loss. The taf project is developing a transfer concept that provides for the implementation of further training workshops and transfer development projects with regional companies.

In the taf project, the chesco research factory is being set up on an area of 5100 m².