Biodegradable polymers

The use of biodegradable polymers can potentially reduce the environmental impact of microplastics, enable specific applications, e.g. in medicine, and reduce the CO2 footprint of polymers if the monomers can be obtained from renewable raw materials and/or the polymer is suitable for chemical recycling.

However, the use of biodegradable polymers presupposes that we can produce them at prices comparable to those of non-degradable polymers and that we can adjust the desired properties. New applications would benefit if we succeed in making properties accessible that cannot be achieved with classical polymers such as PE, PP or PET, for example.

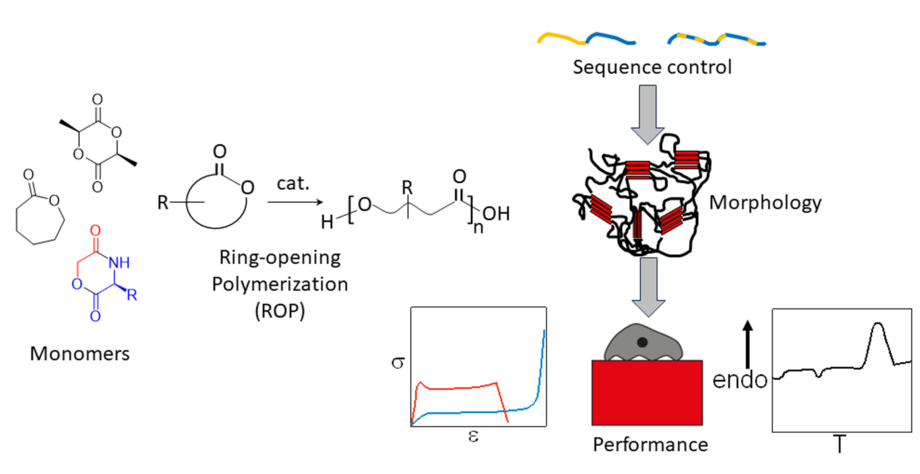

In this context, we are working on the synthesis of monomers, ring-opening polymerization with different catalytic systems, as well as the control of sequence structures, morphologies and properties of the materials produced in this way.

Biopolymer-based hydrogels

Biopolymers such as proteins (especially collagen) and polysaccharides (e.g. hyaluronic acid) are typical components of the extracellular matrix. Materials based on these biopolymers should therefore provide a chemically and mechanically similar environment to tissue.

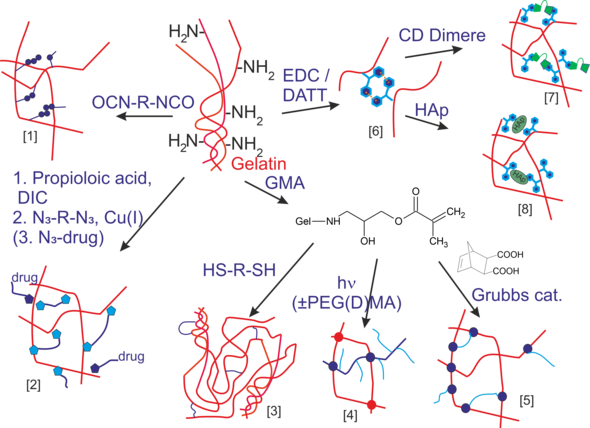

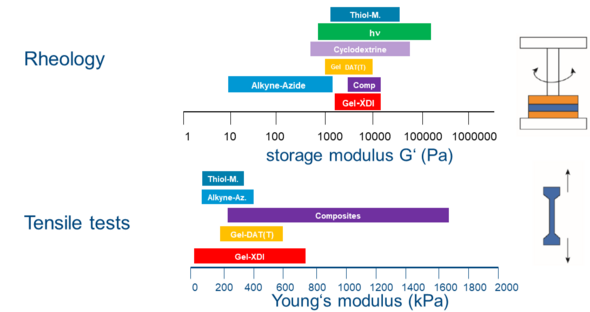

We have developed a whole range of chemical methods to crosslink biopolymers, with a focus on the collagen derivative gelatine, and thus convert them into an insoluble, hydrogel-forming form. In doing so, we were able to adjust the mechanical properties of the gels over a wide range.

Biomedical applications

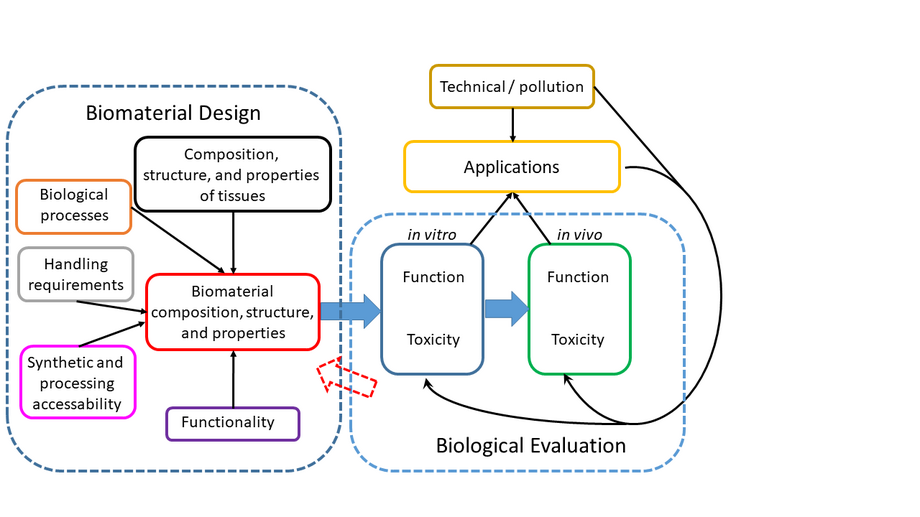

Biomaterial designed for a specific application should use as inputs the results from the analysis of the composition, structure, and properties of tissues; the elucidation of biological and physiological processes; handling requirements and limitations; opportunities in synthesis and processing; and the specification of required functionalities. The latter is linked to the clinical need for the material. Biomaterial design is thus an interdisciplinary endeavour, and a chemist or material scientist working in the field has to understand these inputs. We have worked quite extensively in this respect, working e.g. on implant materials for regenerative therapies, carrier and release systems, as well as materials suitable for fundamental cell culture experiments.

The biomaterial generated on this basis has to be biologically evaluated in vitro and, for most applications, in vivo. This we have typically done in cooperation. Only materials passing both functional and toxicity tests for a certain application can be categorized as biocompatible in view of the studied application—biocompatibility is not a material property!