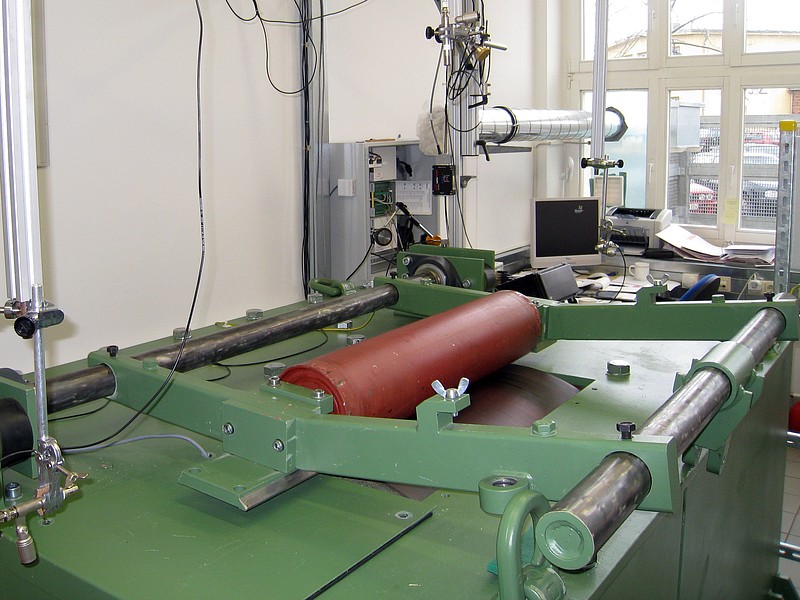

The machine element and idler roller test rig, a cooperative project between BTU Cottbus-Senftenberg (formerly Hochschule Lausitz (FH)) and Lausitz Energie Bergbau AG (LEAG), can be used to examine the mechanical and acoustic properties of rotating machine elements and idlers of a high-performance belt conveyor. With the measuring techniques and methods developed at the BTU in Senftenberg, the idler test bench can demonstrate the properties of an idler as a function of its circumferential speed under the most realistic operating conditions possible. The development of the sound power level with changing circumferential speeds of the idler roller is of interest here. If the sound power level of a new idler is known, the noise emission of a new high-performance belt conveyor system can be estimated using suitable models and calculation methods. As open-cast mining annexes move ever closer to inhabited areas, regulations and laws must be observed to protect people and nature.