Dissertation congratulations

The Department of Engineering Mechanics and Machine Dynamics congratulates our research assistant Lukas Richter on his successful PhD with the topic „A continuum thermomechanical approach for FE modelling of rate-dependent material behaviour under consideration of damage effects“. Mr. Richter has received the title "Doctor of Engineering" with distinction and the whole team is pleased with his achievement. Congratulations!

A part of the results was published in the Journal MDPI Applied Mechanics 5(3).

Project Weimar Excellence Initiative

Our application was approved as part of the Weimar Excellence Initiative 2024. In the project, we will work with colleagues from the Université Polytechnique Hauts-de-France (UPHF) in Valenciennes and the Politechnikum Poznan (PUT) to develop the fundamentals for a research training group “Flexible Microstructure, Customized Materials in Bio-medical Engineering and Technologies”. The work on this will take place in 2025.

Project-related exchange of persons

We have received positive votes for three of our innovative projects as part of the DAAD programme for project-related exchanges.These projects are characterized by their pioneering research and international cooperation. Below we present the projects and their partners:

Wroclaw University of Technology: this project focuses on the "Influence of recycled, selectively laser-sintered PA12 on microstructure". It combines experimental investigations with numerical simulation to better understand the properties and applications of recycled materials.

IPPT (Instytut Podstawowych Problemów Techniki Polskiej Akademii Nauk), Warsaw: An "Experimental investigation and thermomechanical modeling of the material and damage behavior of additively manufactured austenitic stainless steels under cryogenic conditions" is being carried out here. This project promises significant insights into Materials Science, especially with regard to cryogenic applications.

Poznan University of Technology: The focus is on "Numerical modeling and determination of the mechanical properties of additively manufactured PEEK materials for medical implants". This research has the potential to significantly improve the development and application of medical implants.

These projects underline our commitment to international cooperation and scientific progress. We would like to thank the DAAD for their support and look forward to the exciting developments that will emerge from these partnerships.

Obituary for Prof. Dr.-Ing. habil. Rainer Franke

We are sad to announce that our colleague, Prof. Dr.-Ing. habil. Rainer Franke, passed away on January 02, 2024. As a long-standing senior member of staff at IMA Dresden, he supported our group over the last five years in deriving complex engineering tasks from technical challenges. With his outstanding knowledge of Physics and Metallography, he helped us to formulate and solve valuable problems. We will always remember our colleague as a friendly and active person.

Successful habilitation procedure

We are extremely pleased that Dr. Robert Roszak successfully completed his habilitation on 8.11.2023 on the topic "Fluid Structure Interaction Analysis Considering the Structural Behavior". The entire research group is extremely proud of this outstanding achievement and is delighted with Dr. Roszak. We sincerely wish him continued success on his academic path.

Max Grünebaum Award

We are delighted that our esteemed colleague, Dr. Daniela Schob, was awarded the Max Grünebaum Prize for her outstanding dissertation on 15.10.2023. The entire research group under the direction of Prof. Matthias Ziegenhorn is proud of this well-deserved award and wishes Dr. Schob continued success on her academic path.

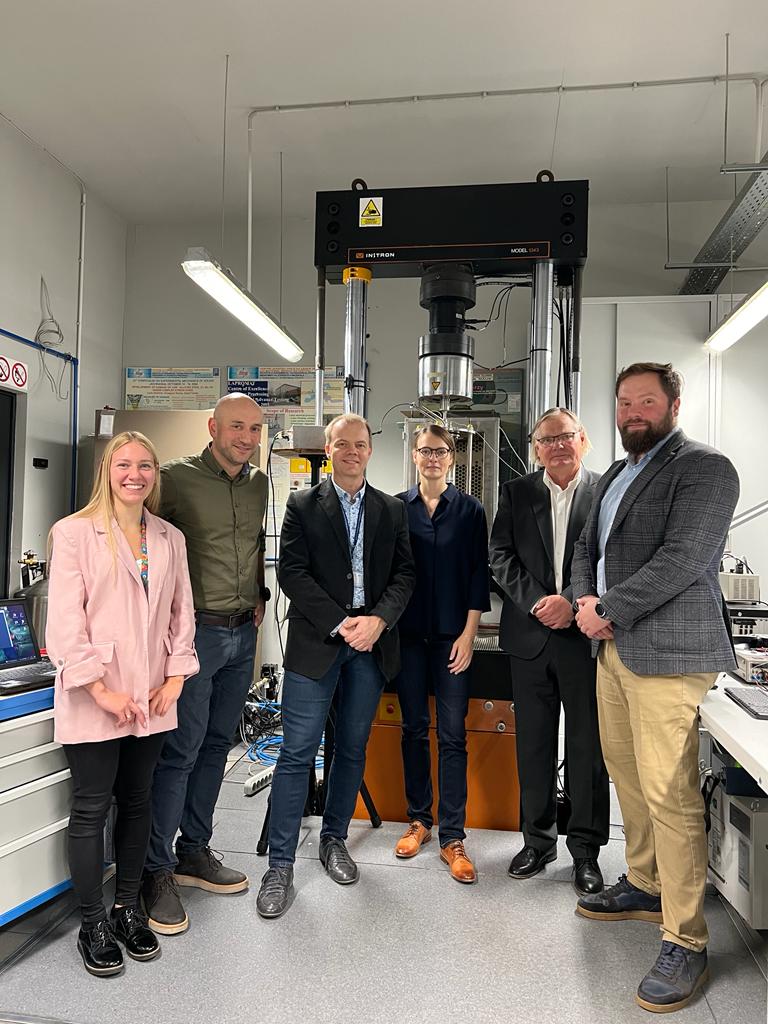

Research cooperation with the IPPT in Warsaw

In the course of a scientific cooperation, the Chair of Engineering Mechanics and Machine Dynamics visited the Institute of Fundamental Technological Research of the Polish Academy of Sciences in Warsaw on 20.10.23 . A central topic was the analysis of the material behavior of additively manufactured metals at cryogenic temperatures. Experts Dr. Jakub Tabin and Dr. Mateusz Kopeć from the Experimental Mechanics Department were responsible for the experimental performance, under the leadership of Prof. Zbigniew Kowalewski. Specimen fabrication was performed by Dr. Robert Roszak from the University of Technology in Poznan. This successful collaboration lays the foundation for future projects and deepening of cooperation between the institutions.

Dissertation congratulations

The Department of Engineering Mechanics and Machine Dynamics congratulates our research assistant Holger Sparr on his successful PhD with the topic "Thermomechanical analysis of inelastic deformation processes under complex loading in modeling and experiment". Mr. Sparr has received the title "Doctor of Engineering" with distinction and the whole team is pleased with his achievement. Congratulations!

DAAD - Project

Together with the Institute for Laser Technologies, Automation and Production Organization of TU Wroclaw, we will work on the topic "Application of functional high-resolution computed tomography for numerical simulations and mechanical testing of additively manufactured aluminum alloys" over the next two years. The exchange of persons is funded by the DAAD.

Dissertation congratulations

We are pleased to announce the completed PhD of our research assistant Daniela Schob. With the topic "Experimental investigation and numerical simulation of the material and damage behavior of 3D printed polyamide 12 under quasi-static and cyclic loading". She received the title "Doctor of Engineering" with distinction. Congratulations from the entire team of the Department of Engineering Mechanics and Machine Dynamics!

EUNICE - Selected chapters of the theory of applied mechanics

From 28th to 30th June 2022, as part of the cooperation between the Institute of Applied Mechanics of the Poznan University of Technology and the Chair of Mechanics and Machine Dynamics of BTU Cottbus Senftenberg, a course was held as part of the university alliance EUNICE. The thematic focus was selected chapters of the theory of applied mechanics. The course was offered to students of mechanical engineering and consisted of lectures and practical application with the finite element software Ansys. The lectures were given by Prof. Dr.-Ing. Matthias Ziegenhorn from BTU Cottbus Senftenberg. The practical part using the Ansys software was led by research assistant Philipp Maasch. At the end of the course, the students received certificates. The course is part of a long-term cooperation between Poznan University of Technology and BTU Cottbus Senftenberg in the field of mechanics and biomedical engineering.

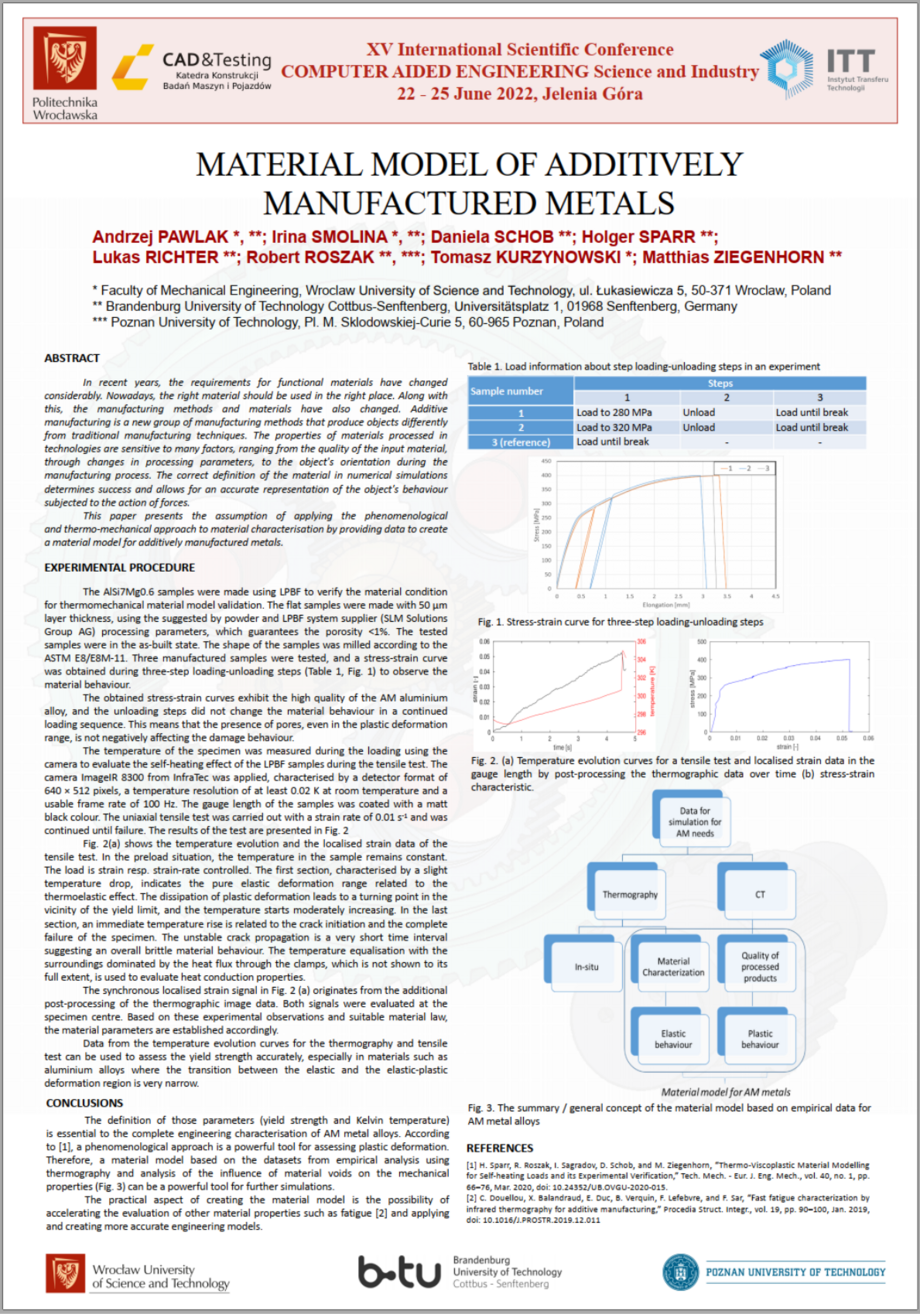

2nd place at international conference

Under the direction of visiting scientists Dr. Irina Smolina and Dr. Andrzej Pawlak, second place was won in the poster competition at the 15th International Conference Computer Aided Engineering. The research focused on creating material models for additively manufactured metals.

DFG project funding Electrically-controlled thermo-mechanical 3D microchannel composites

Together with the research group led by Prof. Adelung at Christian Albrechts University in Kiel, a jointly planned DFG project was approved. The aim of the project is to develop and investigate multi-scale, functional interpenetration composite structures whose physical properties can be changed in a controlled and reversible manner by applying an electrical stimulus. The concept is based on microstructured polymers that are permeated by a disordered network of interconnected micro-channels. By selectively coating the microchannel walls with a thin layer of conductive nanomaterials, such as graphene, electrically conductive interpenetrating composites are created that are characterized by an extremely low volume fraction of conductive material. Thereby, the mechanical properties of the matrix material remain virtually unchanged. Simultaneously, this functionalization enables rapid heating of the composite by Joule heating.

Binationale doctorates - TU Poznan und BTU

As part of a joint agreement between the Poznań University of Technology and BTU Cottbus-Senftenberg, we offer joint doctorates between the partner universities. The fields of mechanical engineering and biomedical engineering are supported. Details on the topics can be found here and further information can be found here.

Participation in the Colloquium for Applied Mechanics Materials, Design and Biomedical Engineering in Poznan

The Colloquium on Applied Mechanics, Materials, Design and Biomedical Engineering was held this year at the Poznan University of Technology. Organized by the Faculty of Mechanical Engineering and the chair of Engineering mechanics and machine dynamics of BTU Cottbus Senftenberg, the event is a continuation of the intensive cooperation between German and Polish scientists. During the colloquium, topics in the field of additive manufacturing, hybrid electric propulsion systems for climate-neutral flying and biomedical engineering were presented by PhD students and scientists from both universities.

Project funding for Dr.-Ing. Irina Smolina

Dr.-Ing. Irina Smolina (Fellow in the Fellowship program at BTU) recently received a project grant entitled "New generation aluminum-based alloys processed by laser additive manufacturing for industrial applications" (AddAluMat) under the "Lider" program of the National Center for Research and Development (Poland). The AddAluMat project aims to develop a technology for processing functional aluminum alloys (5xxx series) using laser powder bed fusion (LPBF) technology and the possible use of additives for aluminum alloy powders to obtain a uniform structure of processed objects used in a wide range of industrial applications. A selected demonstration part from an established industry (including automotive and/or marine) will be subjected to topological optimization and fabricated by the LPBF process using a developed alloy. The "Lider" program of the National Center for Research and Development is aimed at young scientists (up to seven years after their PhD) from various scientific and research institutions and from industry, regardless of their passport and citizenship. The condition is that they conduct research in Poland. (Photo - Press-materials of NCBR)

Visiting Scientist

Dr. Irina Smolina

Dr. Irina Smolina works at Wrocław University of Science and Technology (WUST, Wroclaw, Poland) in the Department of Laser Technologies, Automation and Production Management and the Center for Advanced Manufacturing Technologies (CAMT, Wroclaw, Poland). During the BTU Flagship Fellowship program, Irina will conduct the project "Influence of aluminum alloy powder reuse on the quality and mechanical properties of L-PBF coated samples". This research project will be conducted at Brandenburg University of Technology (BTU) and Wroclaw University of Science and Technology (WUST). The aluminum alloy research specimens will be fabricated using L-PBF (Laser Powder Bed Fusion) technology at CAMT, while at BTU-Cottbus-Seftenberg Dr.-Ing. Irina Smolina will analyze the mechanical properties of the specimens.

Dr. Maciej Obst

Dr. Maciej Obst is a visiting scientist of TU Poznan at our chair since December 2021. His scientific work includes experimental and analytical research of mechanical properties of materials, dynamic systems and safety in road traffic. Research activities include motor vehicle safety engineering, transportation problems and biomechanics related to material properties and structures. His experience and scientific activities are focused on classical materials testing, biomaterials such as bone properties investigation and rheological problems.

M. Eng. Grażyna Olszewska

Ms. Olszewska received her Master of Engineering degree from TU Poznan in the summer of 2020. She has been a PhD scholar since January 2022 and is developing a controller for the Stäubli TX200 robot at our department. The controller will provide a way to test complex stresses for human implants and identify their mechanical properties.

Guest Professor at Poznań University of Technology

At the end of 2021, Prof. Ziegenhorn was a Guest Professor at the Poznań University of Technology. The lecture series was addressed to both students and staff of the Institutes of Applied Mechanics and Machine Design, Mechatronics and Biomedical Engineering. The aim of the lectures was to provide a practical approach to solving complex engineering problems using engineering mechanics, higher strength theory and FEM.

The guest professorship is based on more than ten years of cooperation with Prof. Olaf Ciszak and assoz. Prof. Pawel Jasion of the Institute of Applied Mechanics of the Poznan University of Technology.

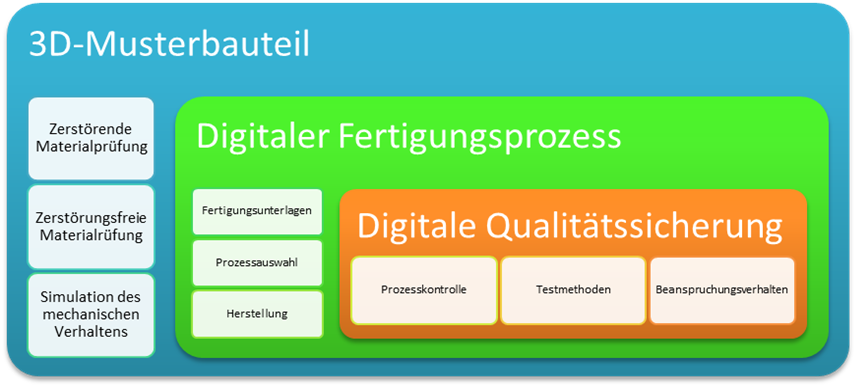

Aviation Research Program - LuFo VI March 2021

In the national aviation research program (LuFo VI), an efficient certification process for additive manufacturing as a technology in aviation is being developed and qualified with an interdisciplinary consortium. For this purpose, integrated solutions for quality assurance and for component and process certification must be developed.

The aim of the project is to develop standards for additive manufacturing further and to establish a self-learning Big Data and AI-based platform for digital testing and certification processes in additive manufacturing. The work of the BTU - research group is focused on joints between existing construction and additively manufactured components.

The project will be realized in the period from 2021 to 2025.

Partners in the project are: IMA Materialforschung und Anwendungstechnik GmbH, Inquence GmbH, AM Metals GmbH, Institut für Luft- und Raumfahrttechnik of TU Dresden and Fraunhofer Institut für Verkehrs – und Infrastruktursysteme.

WIR! – Innovation and structural transformation March 2021

The funding decision for the project Digitalization in Material Testing in the program WIR! – Innovation and structural transformation within the WIR! alliance has been received.

In order to improve the design and mechanical simulation of repaired components and spare parts, particularly with regard to strength properties and service life, a systematic methodology is being developed that allows application-specific material parameters to be determined using suitable testing methods based on given application requirements (load cases, environmental conditions) and process parameters.

The solution forms a complete process chain from damage analysis, digitization of manufacturing documents or generation of new design documents, selection of the manufacturing or repair process and testing of the component to certification and delivery.

The project will be realized in the period from 2021 to 2024.

Partners in the project are: TAKRAF GmbH Lauchhammer, Vattenfall Hydro GmbH Berlin, imq - Ingenieurbetrieb GmbH Hagenwerder, Grasse Zur Ingenieurgesellschaft mbH Berlin and Lausitz Energie Bergbau AG as associated partners.

TAKRAF GmbH Lauchhammer, Vattenfall Hydro GmbH Berlin, imq - Ingenieurbetrieb GmbH Hagenwerder, Grasse Zur Ingenieurgesellschaft mbH Berlin sowie Lausitz Energie Bergbau AG, als assoziierte Partner.