Projects

Optical extensometer for servo-hydraulic testing machine

videoXtens 2-120 HP - Highly accurate and reproducible tensile modulus values

- Testing of plastics and metals

- Accuracy class 0.5 according to EN ISO 9513.

- Highly accurate tensile modulus testing according to ISO 527-1

Technical parameters

- Resolution at room temperature: 0.15 µm

- Frame rate / measured value acquisition rate, max. 500 fps / Hz

- Initial gauge length: 5 ... 100 mm

- Measuring distance, max.: (110 - initial measuring length) mm

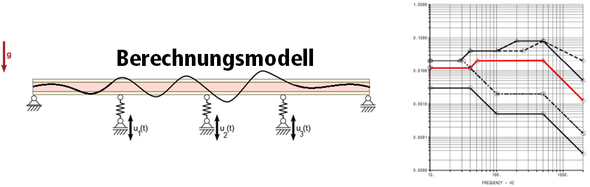

The measuring device forms the basis for systematic studies of microstructural changes in material specimens and component tests during static and moderate cyclic tension-compression or bending loading.

In view of the test equipment available, a major reason for procurement is the strain-rate-controlled test procedure in accordance with ISO 6892-1 for strain-

0.01 1/s in a closed control loop.

Standard testing on specimens is geared to a measuring length range of 3 to 120 mm, with the accuracy achieved satisfying class 0.5 to DIN EN ISO 9513. A test

The aim is to carry out the test with the existing temperature chamber while maintaining the same accuracy. For 3- or 4-point bending tests, thin sheets up to a specimen thickness of 1 mm were measurable.

This project was funded by the European Union.

Graphene Electrical Fibers

Within the program for the promotion of research, innovation and technologies (ProFit Brandenburg) by funding of the European Union and the Investment Bank of the State of Brandenburg, the project "Electrical conductors on polymer basis by functionalization of polymer fibers by means of nanoparticles" is carried out.

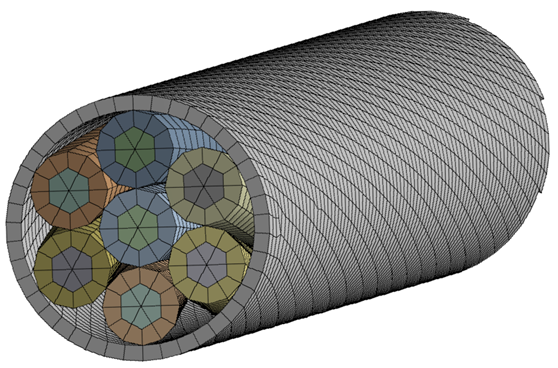

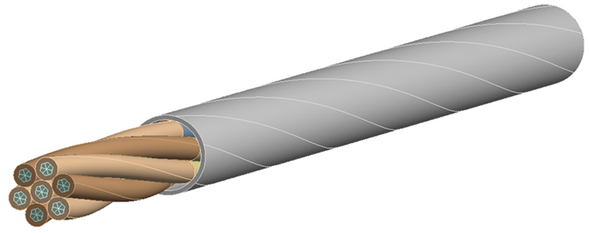

The aim of the project is to investigate the possibilities of a manufacturing and processing technology for polyester fibres functionalised with nanoparticles. The functionalised polyester fibres are to be produced by spinning them into ready-made cables which at least match or exceed the characteristic properties of metallic conductors.

The project will be completed within the next 36 months. An annual public colloquium is planned in which the current results are presented - and users are invited to implement them. A cooperation with institutes of the BTU is expressly desired.

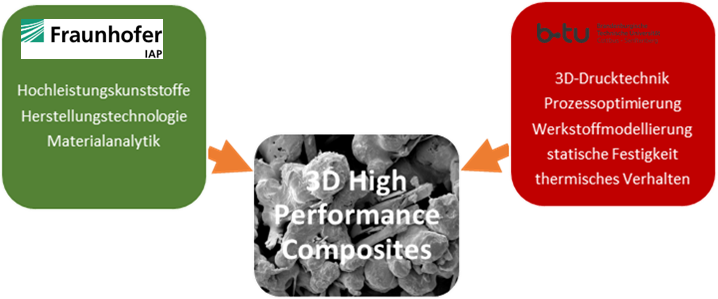

3D High Performance Composites

Since May 1st 2018, the professorship and the Fraunhofer Institute for Applied Polymer Research (IAP) - Research Division Polymeric Materials and Composites got the approval for the project “Investigations on the fabrication and modeling of the strength behavior of high-performance composite plastics using 3D printing - 3D High Performance Composites”. This is carried out within the guideline of the ministry of Science, Research and Culture (MWFK) "strengthening of technology and application-oriented research and science in the state of Brandenburg" (StaF - directive).

Servohydraulic testing machine with 3D motion and deformation sensor

Servohydraulic testing machine

+/- 25kN 100 Hz

Temperature chamber

Range: -70 ° C ... 350 ° C

3D motion and deformation sensor

4M sensor Principle of digital image correlation Image rate by resolution: 2400x1728 pixels up to 168 Hz Focal length 50mm Measuring range from 25x18mm² to 230x170mm²

The characterization of functional dependencies between microstructure and external stress is to be carried out by means of the servohydraulic testing device. The test equipment is the basis for systematic studies of microstructural changes during static and dynamic tensile, compressive, bending or shearing loadings. The equipment with the monitoring system allows a differentiated evaluation of the stress process and damage in combination with the recording of the mechanical parameters. This analysis is an indispensable prerequisite for the following mathematical description of non-elastic material behavior.

This project has been funded with support from the European Commission.

GRMH2TANK

![[Translate to Englisch:] Prinzipieller Aufbau](/fileadmin/user_upload/b-tu.de/fg-technische-mechanik/projekte/graphene.png)

GZ: ZI 1596/1-1; AOBJ: 624204 High-performance and lightweight Graphene-CFRP compressed Hydrogen storage tank for aerospace applications Projektpartner: University of Kiel – Institute für Material Science, Leibniz-Institut für Polymerforschung Dresden e. V.,GleXYZ (Portugal), Onera (France) Duration: 24 Months

Hot-End

![[Translate to Englisch:] Druckverfahren](/fileadmin/user_upload/b-tu.de/fg-technische-mechanik/projekte/Hotend.png)

FKZ 16KN021251 (ZIM)

Development of a 3D-Polymer-Printer with an innovative Printhead-System for well-composed Polymer Mixtures and the Manufacturing of Components with locally optimized properties

Partners: Teyfel Automation GmbH, QPAC GmbH, University of Kiel – Institute for Material Science

Duration: 31.05.2018

Fatigue behaviour of CFRP structures

FKZ KF2260631EB4 ZIM Project IMA -Development of methods for improving the prediction of fatigue behaviour of CFRP structures (MEER)

Duration: 30.04.2017

High cyclic load and heat generation

FKZN 16KN021202; ZIM Project Qpac/ Infratec „Test station for industrial design and component development as well as quality control on carbon reinforced plastics by analyzing the heat generation under high cyclic load“

Duration: 31.01.2017