Parabolic flight campaign: BTU team optimises fission geometry experiment in weightlessness

All good things come in fifteen! At least when it comes to the number of parabolic flight campaigns carried out by Prof. Dr.-Ing. Christoph Egbers, Chair of Aerodynamics and Fluid Mechanics, and his team. This time it is not a campaign of the German Aerospace Centre (DLR), but one of the French space agency (CNES). The BTU researchers are allowed to fly with their French colleagues in April because the Cottbus researchers have been working closely with the "Le Havre University Normandy" for many years.

Heat exchanger technology is at the centre of the research

Prof. Egbers: "We are delighted to be the only German team out of a total of ten teams to be allowed to fly with us. This is very important for our research. It gives us the opportunity to modify our experiment in line with the insights we gained during the last autumn campaign." The subject of the research is the adaptation of heat exchanger technology to the conditions in space. As the heat generated by machines cannot be dissipated in the same way as on Earth (e.g. by fans), other methods must be established to prevent satellites from overheating and failing. For this reason, the BTU team is working with high voltage and is constantly optimising its cylinder and plate splitting experiments.

The campaign will run for three days, with flights starting in Bordeaux

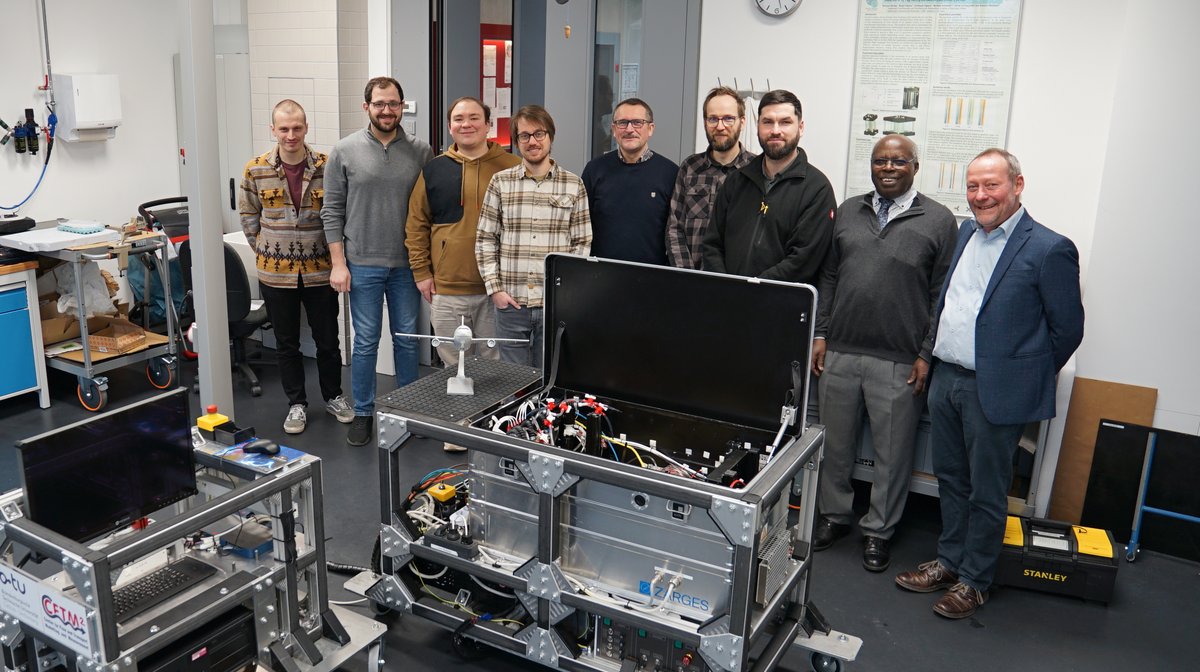

Project manager Dr Vasyl Motuz explains: "We are building everything ourselves down to the smallest detail. As we are experimenting with lasers, liquids and high voltage, everything has to be safe and work flawlessly. In addition, we are in close contact with our French colleagues, who are responsible for the safety of our experiment on the aircraft, for all adjustments and changes to the experimental setup. Everything follows a strict protocol." The level of concentration during preparation is correspondingly high - and the time in zero gravity is precious. Over three days, a total of six sets of five parabolas are flown, each lasting 22 seconds of weightlessness. Every move has to be perfect. The whole thing will take place in Bordeaux. The A310 ZERO-G from the French company Novespace will take off from there.

The flights will be carried out with a specially equipped aircraft. To achieve weightlessness, the pilots fly a special manoeuvre: they bring the aircraft onto a parabolic flight path. The aircraft climbs steeply upwards from a horizontal flight, then reduces the thrust of the turbines and "falls" due to the residual thrust, first upwards and then downwards again after reaching the peak of the parabola, so that weightlessness prevails for a period of 22 seconds. The scientists use this time for their experiments. After each parabola, the aircraft is brought back into horizontal flight. Every day, two members of the BTU team fly along to accompany and conduct the experiment during the flight.

About the experiment carried out on board

The parabolic flight experiment investigates two slit geometries: a plate slit geometry with liquid and a cylinder slit geometry. High voltage and a temperature gradient can be applied in both. The cylindrical slit consists of two vertical tubes, bounded at the top and bottom by plates, and is filled with a dielectric oil. The inner tube is heated and the outer tube is cooled, which leads to a base flow in the gap. If the temperature difference increases, instabilities occur and the basic flow changes. The heat transfer between the pipes is increased.

If an alternating voltage field is applied, this leads to electrohydrodynamic forces that disrupt the buoyancy flow and further increase the heat transport. In microgravity (e.g. in parabolic flight), the force field of the high voltage dominates, which leads to a variety of flow forms, including turbulent flows. These flows and the heat transport can be controlled by the electrical voltage. The flow field is visualised using optical measurement techniques such as shadowgraph and particle image velocimetry (PIV) and the heat transport is measured using special heat flow sensors between the pipes.

Contact us

Aerodynamik und Strömungslehre

T +49 (0) 355 69-4868

christoph.egbers(at)b-tu.de

Press contact

Kommunikation und Marketing

T +49 (0) 355 69-3837

britta.radkowsky(at)b-tu.de