The goal of the Energy and Conversion Lab is to map the four levels for sector-coupled energy systems - heat, power, storage and mobility - in a CO2 neutral closed-loop approach based on green hydrogen.

At each level, all elements will be developed and optimized towards a circular approach, starting with the production of green hydrogen, followed by further processing into synthetic hydrocarbon and nitrogen-based fuels, and their storage, transport and conversion into electricity and heat.

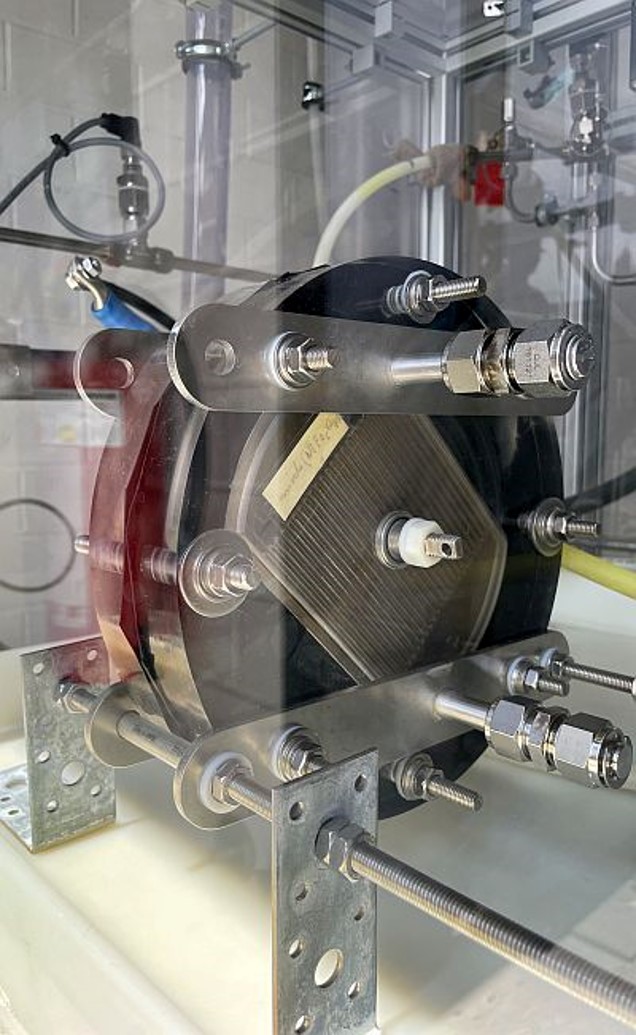

Water electrolysis with anion exchange membrane (AEM) for flexible and efficient hydrogen production

AEM technology development is performed at laboratory scale using multiscale experiments and simulations to develop and verify a novel AEM concept with noble metal-free catalyst and membrane materials. The degradation behavior of the MEA materials will be investigated to evaluate the suitability of these materials for industrial AEM electrolyzers.

- Current scale-up: 100 cm2

- Targeted scale at EIZ: 360 cm2

- Durability: up to 1000 hours of operation

Innovative high-pressure electrolysis for hydrogen production for mobile and stationary applications

Electrochemical conversion of H2O to H2 and O2 at specific tank pressures (>300 bar) is investigated. For this purpose, a novel ring stack design for compact and robust applications is developed.

- Electrochemical conversion at tank specific pressures up to 300 bar and later up to 700 bar.

- Concept development of high pressure stable ring stack designs

- Detailed investigation of membranes, interconnectors and monopolar plates

Optimized methane and methanol synthesis and catalyst surface characterization

- Development of cerium oxide based catalysts for CO2 hydrogenation at low temperatures and pressures

- Characterization of surfaces by spectroscopic and microscopic techniques (e.g., XPS, EDX, LEEM, PEEM, STM)

- In-situ investigation of surface reactions and reaction mechanisms using NAP-XPS

- Optimization of reactor design regarding energy and conversion efficiency

Closed-loop power-to-X-to-power process for CO2-neutral and emission-free energy storage

A power-to-X-to-power laboratory to study the interaction of renewable energy, electrolysis, methane/methanol synthesis and thermal energy conversion

- Oxy-methane and oxy-methanol in gas engines

- Development and improvement of reaction mechanisms for the oxidation and reduction of methane and methanol

- Co-simulation and optimization of energy storage systems