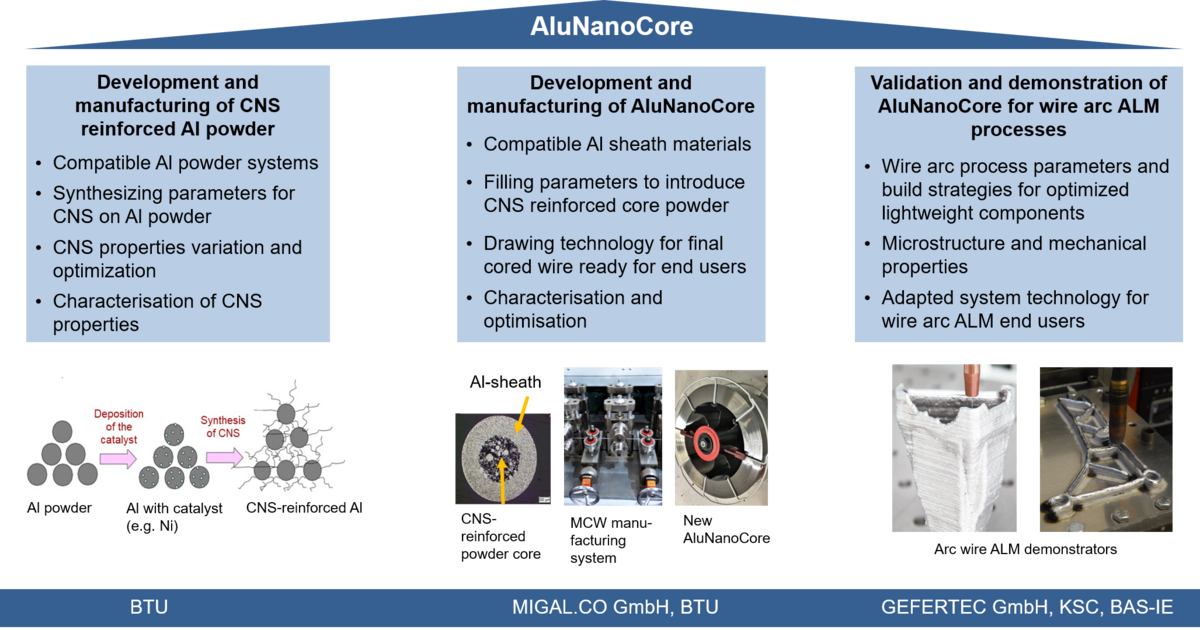

AluNanoCore High strength nano reinforced aluminium powder cored wire for arc based additive layer manufacturing (ALM)

Motivation and objectives

Cost effective wire arc-based additive layer manufacturing (ALM) processes have the potential to deliver high build-up rates for large volume components. However, for the production of lightweight aluminium components, there exist currently only a limited range of low strength standard solid wires, which are primarily designed for joint welding. Wires for the production of high-strength lightweight components, such as Titan materials, are limited available for high-technology applications and very expensive. Carbon nanoparticles offer excellent potential for significantly increasing the strength of aluminium without subsequent heat treatment. However, the addition of nanoparticles unbound and separately introduced to the matrix material has two inherent problems. On the one hand, the light nanoparticles can pose a health hazard during the supply and on the other hand, their uniform distribution is difficult to ensure, since they float.

The project aims to develop an aluminium cored wire (AluNanoCore), which represents a fundamentally new type of filler material for wire arc ALM and enables the safe and uniform addition of carbon nanostructures - CNSs (a mixture of nanotubes and fibers). The introduction of the metal-matrix composite powder into the cored wire is done intrinsically as a powder core, which is enclosed by a solid sheath. The CNSs are first synthesized from a gas phase directly on the surface of Al powder. This type of "breeding" allows a more homogenous distribution of CNS locally on each individual particle and globally in the powder. A separate CNS handling during processing is avoided, which brings significant advantages compared to separate merging of powder and nanoparticles, especially from the point of view of occupational safety. In the next step, the processing of the cored wire is carried out by filling the core inside the sheath with the CNS-Al composite powder and drawing the entire system to the wire end diameter. AluNanoCore offers a flexible alloy system in which the powder and sheath material as well as the concentration and size of the CNS can be variably dimensioned. The main goal of the development is a strength increase compared to conventional AlSi-based materials. With the development, a new class of Al material will be available for the additive production of lightweight components, which has a superior strength-to-density ratio. Due to the significant increase in strength, lightweight construction components with reduced wall thicknesses and cross sections can be produced.