Course "International Welding Engineer"

From design to manufacturing, engineers with extensive joining knowledge are needed to handle the extensive design and production tasks in diverse industries:

- Automotive

- Aerospace

- Rail vehicle construction

- Mechanical and plant engineering

- Shipbuilding and marine engineering

- Construction

| Contact |

|---|

| Dipl.-Ing. Cord Hantelmann |

After successful evaluation of the course offer by the Schweißtechnische Lehr- und Versuchsanstalt (SLV) Berlin-Brandenburg, it has been possible since the beginning of 2007 for students of mechanical engineering (Bachelor, Master or Diploma) and industrial engineering with a specialisation in production engineering (Bachelor, Master or Diploma) at the BTU Cottbus to take part of the additional training to become an international welding engineer. The training is carried out according to the guidelines of the International Institute of Welding (IIW), European Federation for Welding, Joining and Cutting (EWF) and the German Welding Society (DVS) and can be taken parallel to normal studies or as a postgraduate course for graduates of technical colleges and technical universities.

The training to become an International Welding Engineer is divided into three modular parts:

| Part 1: Technical fundamentals (83 h) Intermediate examination |

| Part 2: Practical basics (60 h) |

| Part 3: Main course (298 h) |

| Final examination "International Welding Engineer" |

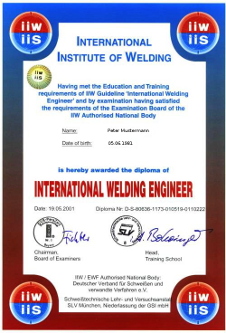

After passing the examination (Part 1 to Part 3), the participant receives a German-language DVS® Welding Engineer certificate and an English-language EuropeanWelding Engineer and International Welding Engineer diploma.

The training in Part 1 "Technical Fundamentals" takes place at the BTU Cottbus through participation in the lectures:

After successful completion of the intermediate examination, the participants are admitted to parts 2 and 3.

The additional qualification "International Welding Engineer" offers excellent career prospects on the national and international job market and qualifies for the assumption of management tasks. The entry or advancement in a company is often connected with the qualification of welding engineer.