Geometry acquisition of turbomachinery components for the modeling of blade mistuning

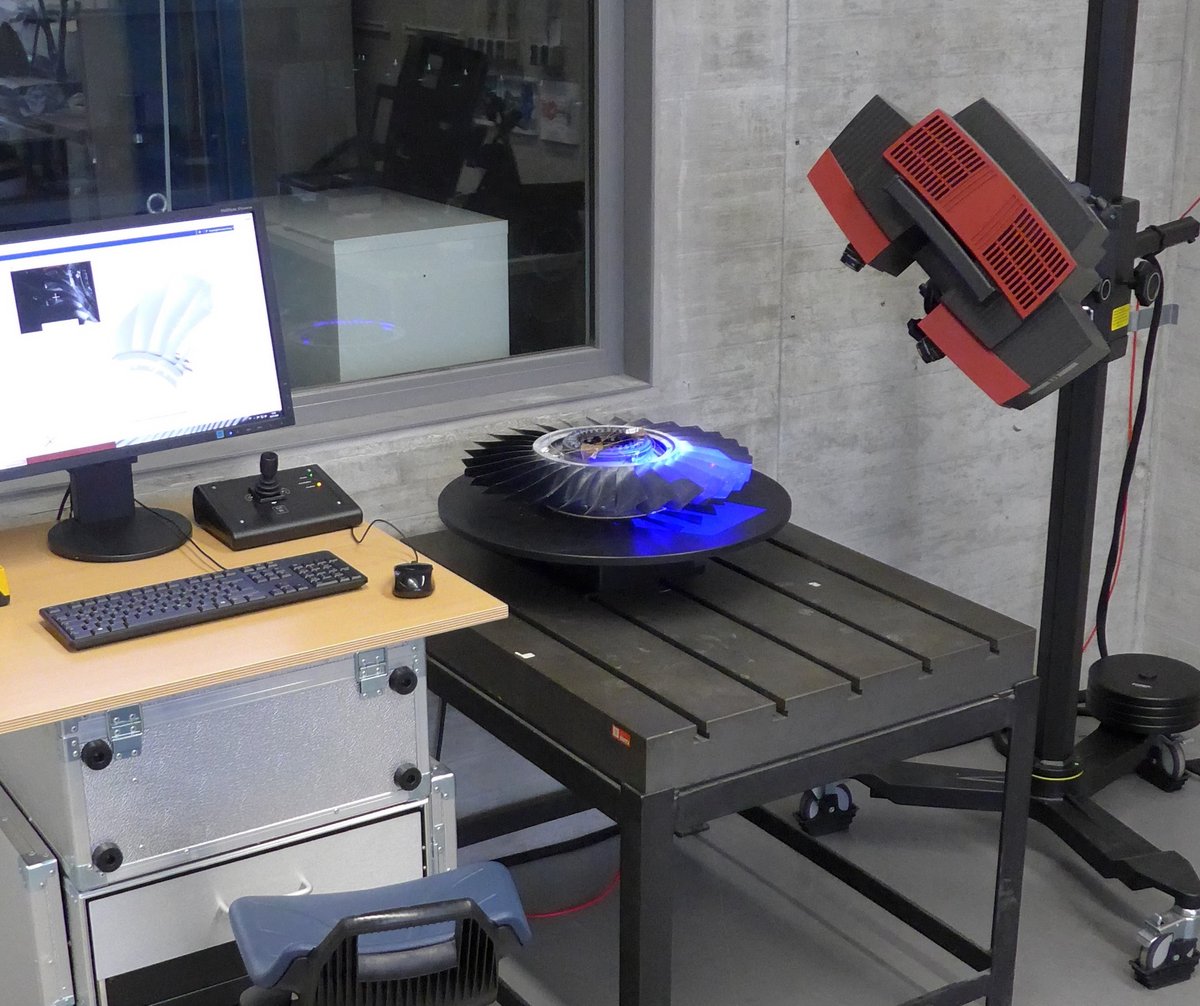

Non-contact optical 3D geometry measuring unit, consisting of:

- Optical 3D-Scanner

- external probe for measuring concealed edges

- Image processing computer

- Control and evaluation software

- Photogrammetry system

Real components always show deviations from the desired design, for example due to tolerances in production. The aim of the project is to investigate the structural dynamic influences of the geometric deviations on compressor and turbine blades.