Laboratory for Vibration Measurement Technology and Lightweight Construction Applications

Vibration measurement technology

Measurement methods

- Experimental Modal Tests

- Systemidentification and Model-Updating

- Operational Vibration analysis

- Durability and Fatigue Strength Tests

- Vibration Elimination and Reduction

Measurement equipment and sensors

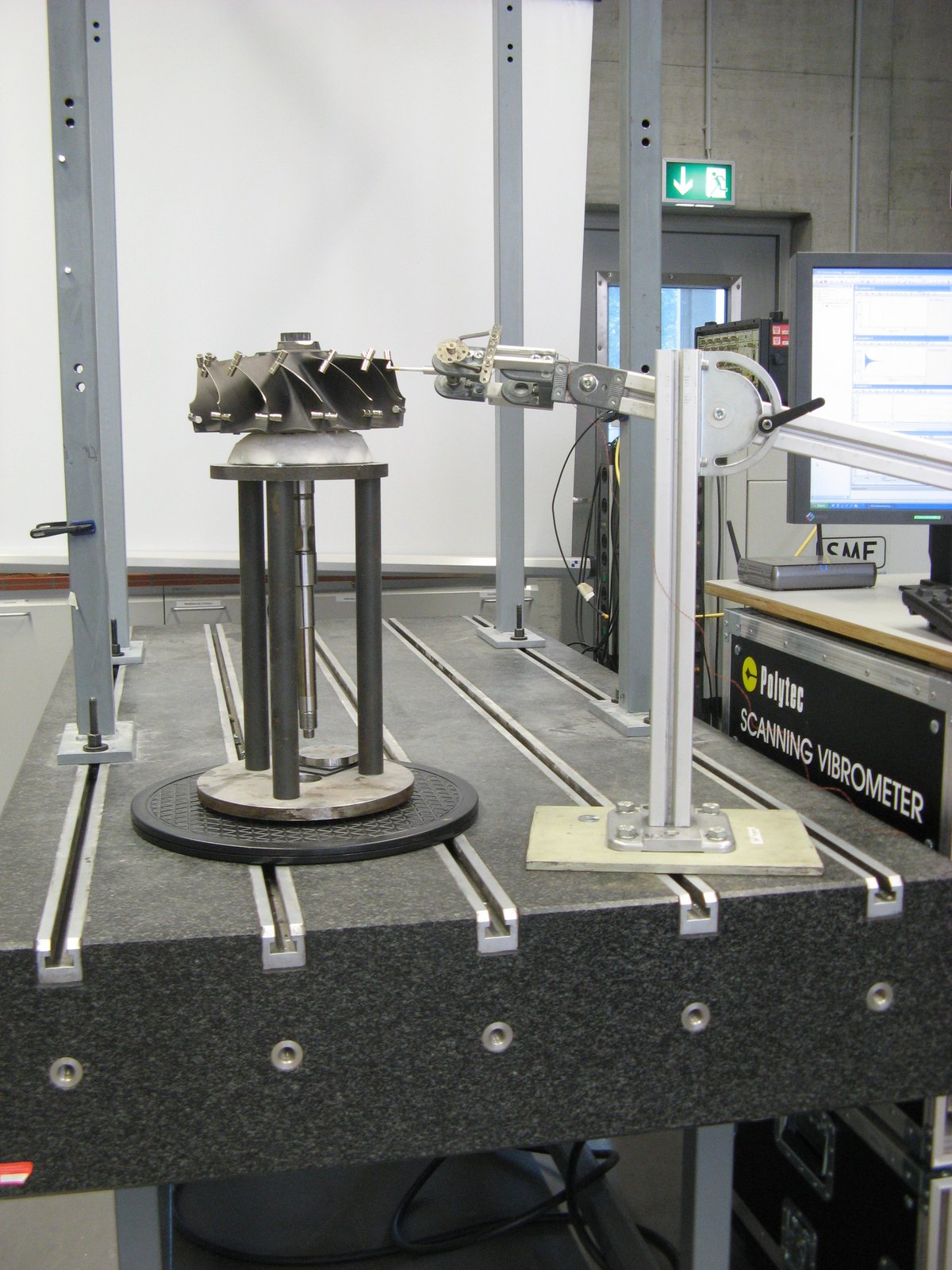

- Laser-Scanning-Vibrometer (Polytec PSV500-B)

- 28-Channel-Frontend (Brüel & Kjaer)

- 5-Channel-Frontend (Brüel & Kjaer)

- 24-Channel-Frontend (Jäger Messtechnik, 16 outp. / 8 input)

- Dynamic Signal Analyser HP35670A

- Laser-Scanning-Vibrometer (Polytec PSV400)

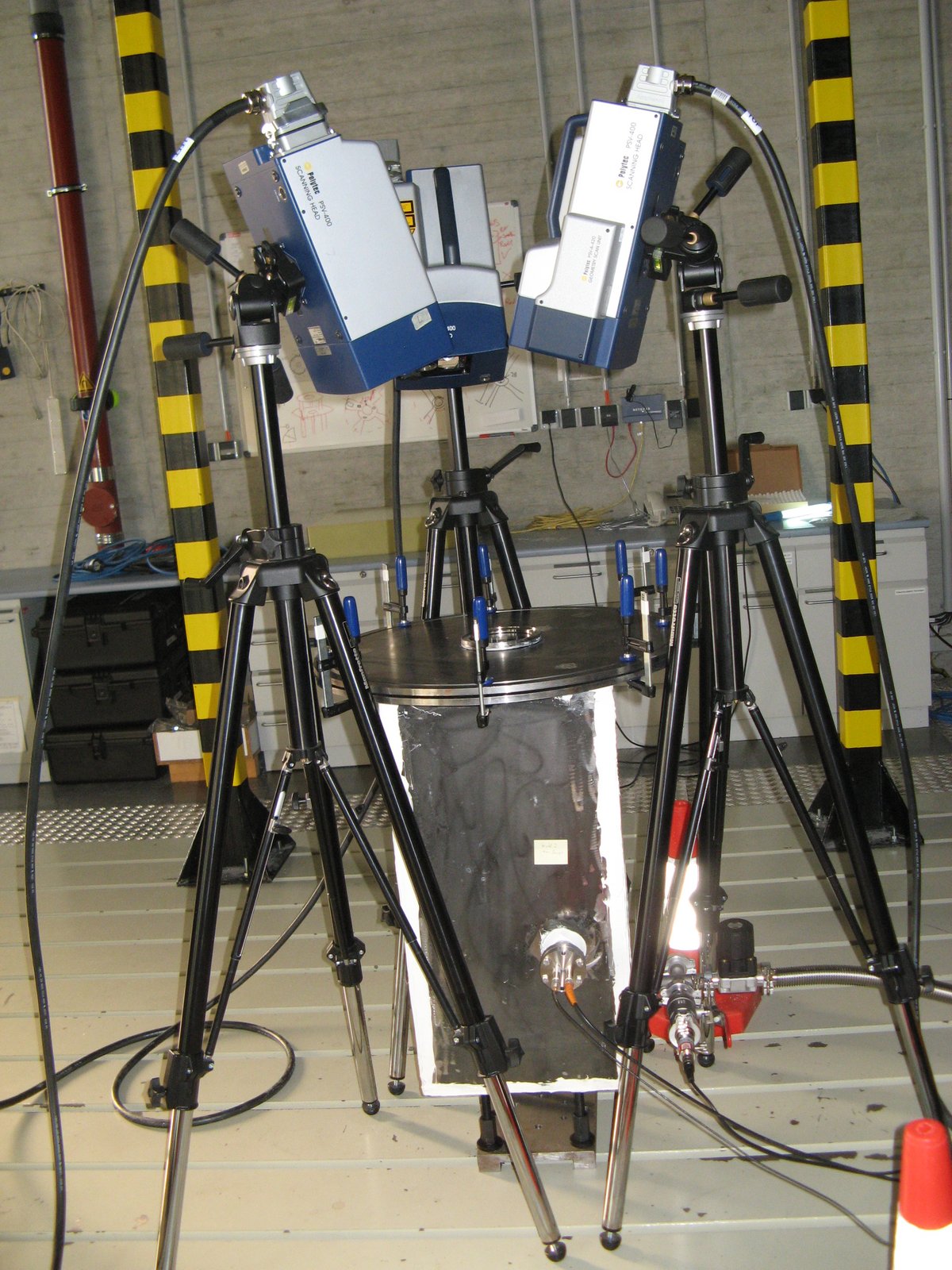

- 3D Laser-Scanning-System (Polytec PSV400-3D)

- Laservibrometer (OFV2500 and Ometron VH300+)

- Strain Gauges Amplifer

- Multi-Shaker Excitation up to 16 channels

- accelerometer and force sensors

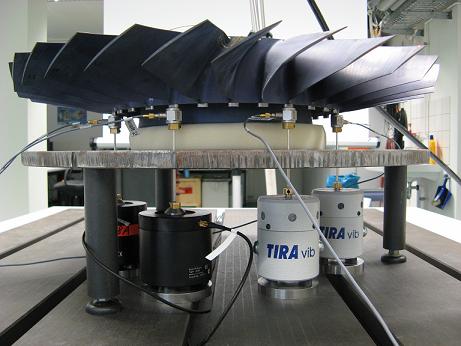

- elektrodynamic Shaker (10, 45 und 200 N)

- Impact Hammers (2 - 450 g)

- Impendance Measuring Head

Software

- Modalanalysissoftware ME'Scope (Brüel & Kjaer)

- LabView, Diadem (National Instruments)

- Operational Modal Analysis Software / OMA (Brüel & Kjaer)

Other Equipment

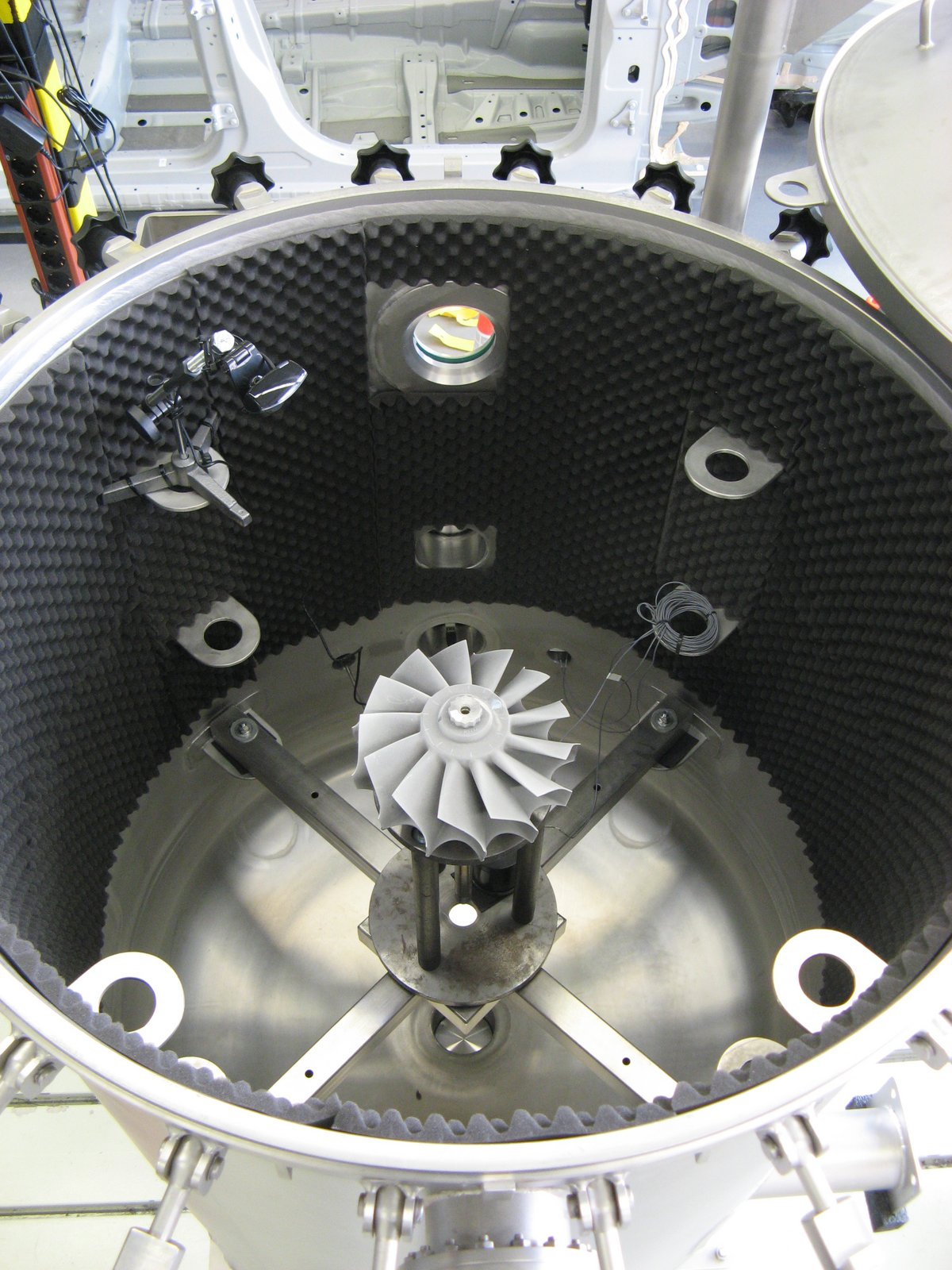

- Pressure and Vacuum Measuring Chamber

- stationary facilities for the construction of test stands

- vibration-insulated foundation

- Stroboscope

- GPIB Interface

A vehicle bodyshell is available for practical training.

Measurements on rotating structures can be performed at the rotation test facility of the Gesellschaft für Entwicklung und Versuch Adlershof mbH (GEVA).

Lightweight applications

The main focus of the chair is the analytical/computational treatment of lightweight structures (fiber composite structures, sandwich structures). In the laboratory there is the possibility to produce lightweight structures (hand lamination) and to carry out some component tests.

All common types of fibres (glass, aramid, carbon fibres) can be processed.