Current Projects

Efficient calculation of shell structures from highly complex CAD models

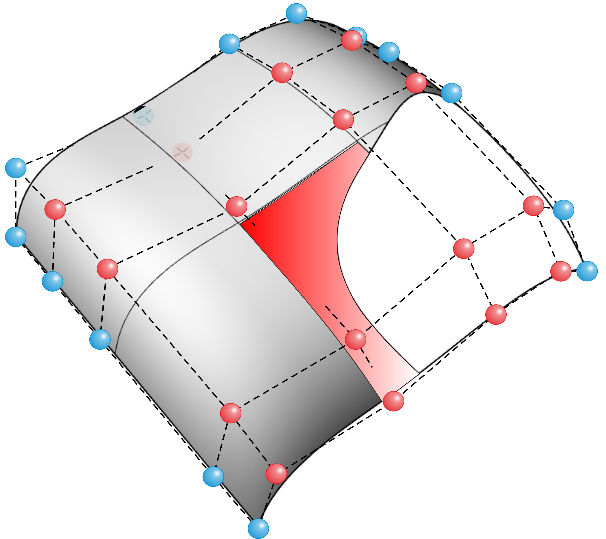

Abstract Over the past decades, a divergence between design and computation has developed in the field of engineering. While the design in computer-aided design (CAD) programs is mostly based on Non-Uniform Rational B-splines (NURBS), and thus the majority of the geometries used can be represented exactly, the finite element method (FEM) with linear Lagrange basis functions dominates in the field of computation. The use of the latter method for computation leads to a faceted approximation of the geometry, and thus requires model conversion, which is often time-consuming and costly. This problem is the main motivation for isogeometric analysis (IGA), which has been researched worldwide since the mid-2000s, and is increasingly finding its way into computational practice as well. Numerous research papers have already proposed successful adaptations of elements and methods to isogeometric analysis, and found highly efficient formulations. One area that continues to require a great deal of research is the efficient and robust computation of highly complex CAD models, which can consist of thousands of individual domains. Although there are already a large number of publications on this topic, no satisfactory solution has yet been found.

In the project Efficient Computation of Shell Structures from Highly Complex CAD Models, which is funded by the German Research Foundation (DFG), this problem is to be researched and solved. For this purpose, a combination of the approach functions of the spectral element method with a NURBS geometry description is developed in order to completely avoid the problem of very small carrier areas in trimmed structures. Since the sub-area structure given in the NURBS geometry model is maintained and the individual sub-areas are meshed independently, the meshing procedure is trivial and requires very few resources. The individual sub-areas are connected using the Mortar method, which enforces equality of deformations along common edges in the weak form.

Author

Dr. Nima Azizi

Funding Institution

DFG, Project number: 503246947

Keywords

spectral element method, trimmed NURBS, area coupling; shell formulation.