Chair profile

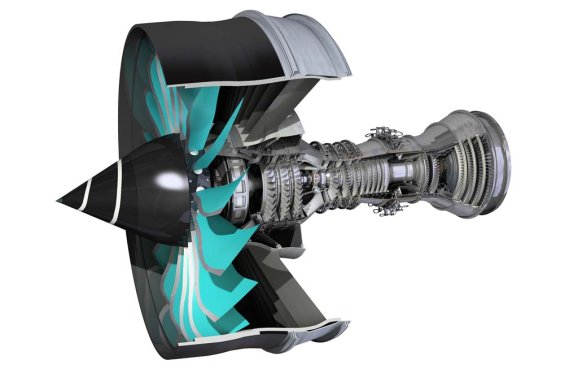

Today gas turbines are the standard engine for many airplanes, designed as turbofan-engine or a turboprop-engine with the help of propellers. The high power density of a gas turbine gives it an advantage over a reciprocating engine, which enables the transport of many passengers or cargo over long distances. The demands of the operators on aero-engines are very high. Low pollutant- and noise-emissions contribute to the protection of the enviroment and residents near airports. Furthermore, a low fuel consumption helps to maintain competitiveness when faced with rising kerosene costs and landing fees. In addition, aero-engines should be affordable, easy to maintain, save and reliable. Safety aspects have such a high priority that development, production and operation of aircrafts and engines are strictly monitored by public authorities.

The enormous progress which was achieved during the last 50 years in terms of fuel consumption, noise emission and reliability is still not sufficient.The increase of the annual global air traffic (nearly 5%) requires a further substantial increase in efficiency as well as the reduction of pollutant- and noise-emissions in order to minimize the impact on the environment. Besides the improvements on aircrafts and air-traffic-control, there is a focus on improving aircraft engines, which determines central research and development goals for decades.

The chair of aero-engine design is part of these various research activities. Besides the increase of gas turbine-efficiency, future aero-engines will be much stronger integrated into the aircraft system. Improvements are not only achieved by the optimizations through the single disciplines such as aerodynamics, combustion, strength and manufacturing, but also through their coordinated, integrative interaction in the exploration of new concepts and principles. The field of conceptual and detailed design is assigned a central role. It brings together the contributions from the single disciplines which are part of a development process, to a manufacturable and by the authorities certifiable concept or component and determines the optimum compromise for a given task.

In the field of research, the chair is concerned with various questions of design development, design planning and the optimized sequence of such processes, as well as with the design of new concepts. Special importance is attached to the fact that the economic aspects such as component- and maintenance costs are considered straight from the beginning. Furthermore safety and reliability aspects, which are especially in aviation a high demanding task, are involved in the design process. System engineering supported by modern analysing programs (FEM, CFD, CAD) and optimization routines are used for the design of new concepts or the development of existing components and concepts. The existing expertise in the fields of design, thermal-, strength- and lifing analyes as well as optimization, but also aspects of airworthiness, safety and reliability are used purposefully.

Despite the existing focus on aircraft engines there are synergies that can be transferred to other areas of the 'hot' mechanical engineering. In particular, this concerns methods of a safe and reliable design of components.

The curriculum of the Department of flight engine design includes all the areas that lay the foundations for the design of safe and reliable components. Next to the engine design, the engine integration, the life cycle calculation and fracture mechanics, the chair includes methods for the design of safe and reliable systems as well as system- and cost-engineering. Social competence and the essential methods for component development within teams (e.g. planning, requirement- and risk-management, validation, presentations) are studied within an exercise to the 'aero-engine design lecture'.