Metal Hydride Technology

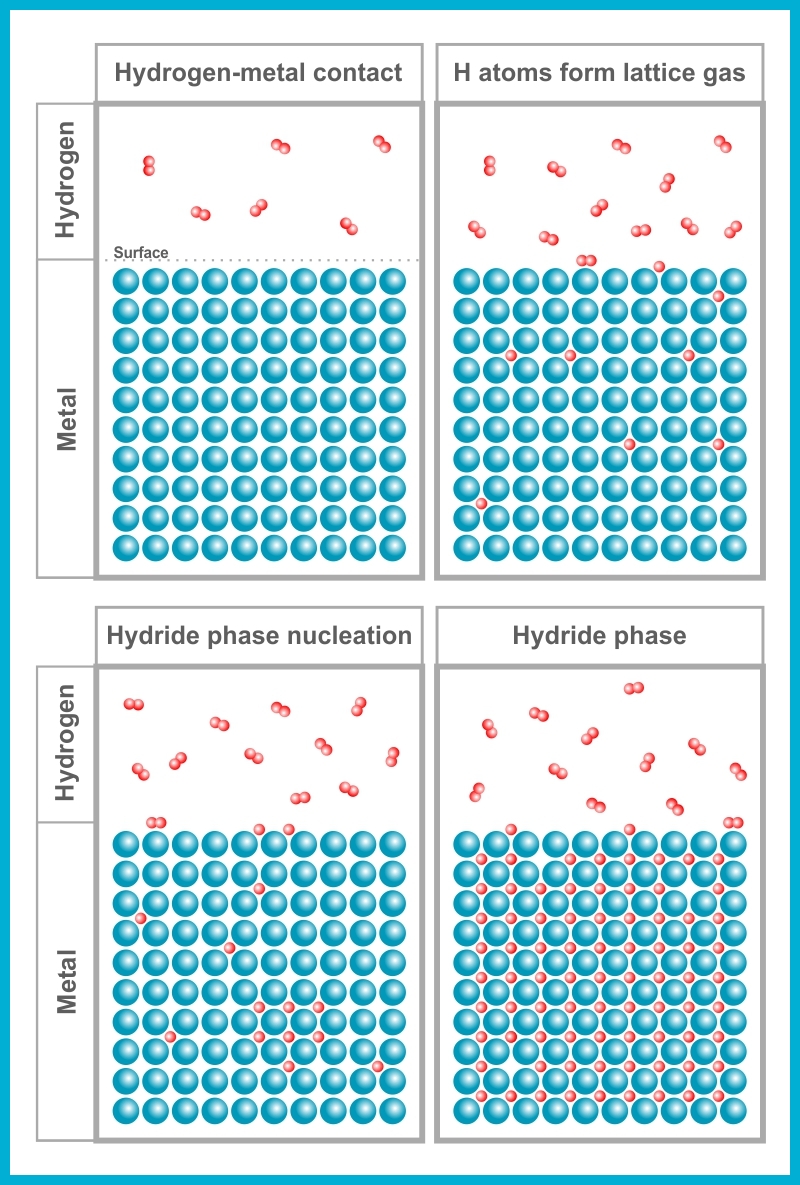

In the evolving landscape of the hydrogen economy, the Hydrogen Research Center at BTU is at the forefront of advancing storage, distribution, and dispensing technologies. Among the promising alternatives to traditional compressed gas or liquid hydrogen storage are metal hydrides as solid hydrogen carriers. Metal hydrides present numerous advantages:

- Safety: They enable the secure storage of hydrogen at moderate operating pressures (typically 1 to 25 bar).

- Efficiency: Offering a compact storage solution, they can hold up to 150 kg-H2/m³ (material-baed) without experiencing boil-off or blow-off losses.

- Intrinsic Safety: Hydrogen is chemically bound within metal hydrides, ensuring that any unintended leaks result in a gradual H2 release rather than a sudden discharge, enhancing safety.

- Energy Storage Efficiency: These thermochemical systems can offer an energy storage efficiency of 80% and more.

- Purity: They release hydrogen gas at a purity of 7.0 and better.

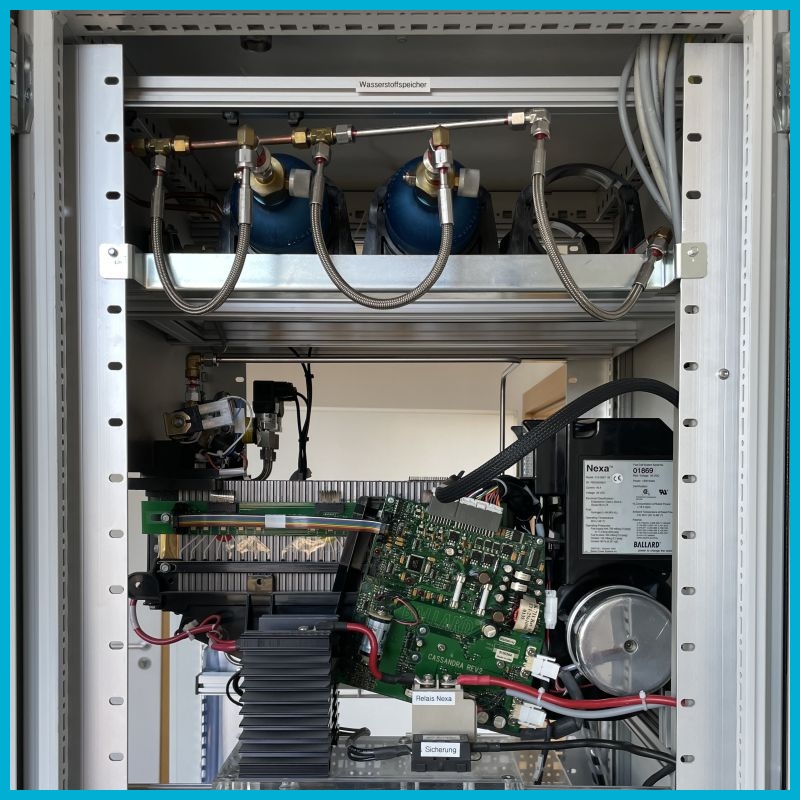

Over the years, various industries have harnessed the potential of metal hydrides. They have powered everything from fuel cell-driven submarines, railed vehicles, and stationary power systems to portable electronics. Moreover, their versatility extends to applications like thermochemical hydrogen compressors, heat pumps, H2 purification systems, actuators, sensors, battery electrodes (Ni-MH), and the selective removal of hydrogen from gas mixtures.

Our Research Focus

At BTU’s Hydrogen Research Center, we are committed to advance metal hydride technology through a blend of experimental and computational approaches. Our research encompasses:

- Advancing hydrogen-absorbing metal alloys tailored for specific pressure and temperature parameters.

- Enhancing the rapid activation of metal hydride-forming alloys through optimized microstructures or catalytic species.

- Boosting the durability and reliability of metal hydride mixtures and composites.

- Analyzing and refining heat and mass transfer mechanisms within metal hydride systems.

- Innovating metal hydride vessel designs for optimal performance.

- Designing storage devices with superior storage capacity and dynamic loading/unloading capabilities.

- Creating sensors and monitoring techniques for metal hydride devices, emphasizing non-intrusive methodologies.

Our Vision

BTU's overarching mission is to propel metal hydride energy systems towards widespread use. This involves integrating metal hydride storage devices with cutting-edge energy conversion technologies like electrolyzers and fuel cells, paving the way for efficient hydrogen energy systems. Join us in shaping the future of hydrogen energy technology.