Anion Exchange Membrane Electrolysis

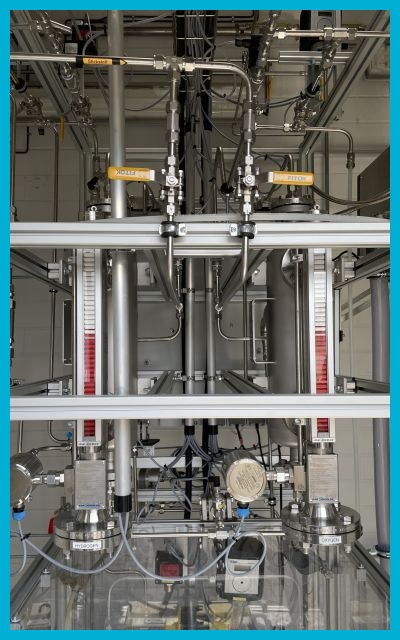

The generation of hydrogen by anion exchange membrane electrolysis (AEMEL) of water is an emerging technology for the furture high-power density and low-cost production of hydrogen. With an AEMEL test rig, we conduct research on the following topics:

- Component tests (electrodes, catalysts, membranes, end and bipolar plates, cell frames, sealings)

- Investigation of different dynamic modes of operation

- In-operando analysis at single-cell level and at short-stack level

- H2 purity analysis

- Multi-scale simulation models (incl. model verification)

Technical specifications

- Operational pressure: atmospheric

- Operational temperature: max. 80 °C

- Usable electrolytes:

- DI water

- Max. 1 M KOH

- Adjustable volume flow rate in electrolyte circle: max. 3 l/min

- Electrolyte feed mode: simultaneous on cathode and anode side

- Operating current (DC): up to 200 A extensible up to 340 A)

- H2 production rate: up to 83 Nl/h (at 200 A)

Cell configuration

- Single cell or short-stack

- Frame material: PMMA

- Active catalyst area: up to 100 cm2

- Testable electrode substrates

- Carbon papers or cloths

- Foams

- Meshes

- Distance electrode-membrane: zero-gap

- Distance electrode-flowfield: zero-gap up to 1 mm

- In-operando investigations: Electrochemical impedance spectroscopy (EIS) and further electrochemical measurement methodes (GAMRY potentiostat & booster)