Completed Projects

5G-Testbed-BB

The goal of this project is the development and testing of 5G applications in the form of testbeds to provide both SMEs and the public sector with practically relevant and innovative concepts and usage scenarios, so called “use case bundles”. For this, new network technologies are being used which fit the needs of the mentioned target audiences and can lead to an increase in innovation in the Brandenburg federal state.

At the chair of automation technology, the following three use cases are being implemented:

- AI-based digital assistance system with data gloves

- Roboter operation through gesture recognition

- Integration of autonomous transport roboters into an assembly line

Project duration

01.05.2023 - 31.12.2024

Funding

The project is funded by the German Federal Ministry for Digital and Transport (BMDV)

Partners

- IHP GmbH – Leibniz-Institut für innovative Mikroelektronik

- Stadt Welzow

- Technische Hochschule Brandenburg

- Technische Hochschule Wildau

- DAKO GmbH

- INNOMANN GmbH

Contact:

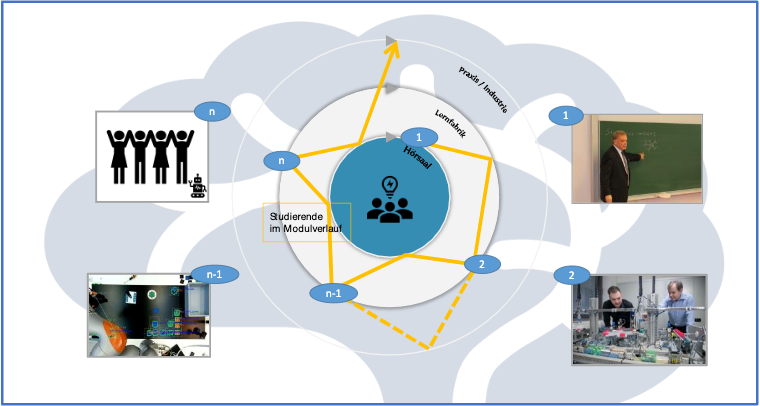

KI@MINT

The sub-project "Practice-oriented teaching concept with an AI learning factory" focuses on the practice-oriented transfer of knowledge for AI solutions to production management problems. The key aspect is the expansion of classic teaching modules to include practical learning elements on a multi-stage production plant and its AI elements. Here, interactions between processes, competing objectives of improvement approaches and various potentials of AI for production processes can be illustrated particularly clearly.

Partner

The project will be implemented with the following disciplines and areas:

- Information, Communication and Media Center / Multimedia Center

- Chair of Graphic Systems

- Chair of Hybrid Constructions - Solid Construction

- Chair of Media Technology

- Department of Applied Mathematics

- Department of Engineering Mathematics and Numerics of Optimization

- Center for Scientific Continuing Education

Further information:

KI@MINT

Project duration:

01.12.2021 – 30.11.2025

Funding:

Funded by the Federal Ministry of Education and Research.

Contact person:

Jürgen Selka

WIR!- WI+R – RepAIreality

Technological, economical and social innovation are keys for a successful structural transformation in the Lusatia region. The subproject RepAIreality provides a foundation for innovation in the areas of maintenance, repair and operations (MRO). On this foundation new scopes of business are becoming possible in the area of MRO which increases the attractiveness of the Lusatia region for both living and working there.

The goals of RepAIreality are the following:

- Development of an AI-based repair-assistance system for the backup of knowledge which can also be used for the training of the workforce.

- Establishing a more attractive image of companies for potential employees in the Lusatia region

- Increasing the effectiveness and efficiency of SMEs in the Lusatia region through digitalization of their processes as well as through the deployment of AR/VR-systems.

This way, RepAIreality is aiming for technological, particularly AI-based, but also economic and social innovations.

Further information: Digitale Reparaturfabrik

Project duration:

01.06.2021 – 31.05.2023

Funding:

“WI+R” is funded by the German Federal Ministry of Education and Research (BMBF) as part of the program "WIR! – Wandel durch Innovation in der Region"

Ansprechpartner:

Mittelstand 4.0 Competence Center

The Mittelstand 4.0 Competence Center Cottbus helps small and medium-sized enterprises in the Brandenburg region to increase their digital competence. The center provides modular offers that support SMEs in the use of digital solutions, depending on their degree of maturity. The human being is the focus. Employees, social partners and executives are, for example through learning partnerships, actively involved at an early stage in order to introduce new technologies and economic systems in an employee-friendly way. The center has special know-how in the following areas:

- Qualification,

- Automation Technology, Digital Factory, Smart Factory,

- Logistics, cyber-physical systems,

- Smart Enterprises,

- IT Security & Privacy.

The free information offered by the Mittelstand 4.0 Competence Center includes the following concrete offers:

- information materials and events,

- business talk and company visits,

- seminars, demonstration events, trainings in the training laboratory,

- Training-on-the-job, online seminars, online training modules and video tutorials,

- Learning partnerships

- Support of implementation projects in companies.

Trainings of the competence center are carried out both in the model factory at the Brandenburg Technical University Cottbus - Senftenberg, in the training centers of the project partners as well as directly on site in companies.

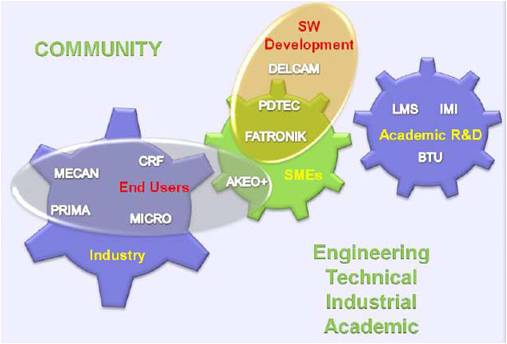

Project partners

Partners of the Mittelstand 4.0 Competence Center Cottbus are the Brandenburg University of Technology Cottbus - Senftenberg (consortium leader), the University of Applied Sciences Wildau, the University for Sustainable Development Eberswalde, the IHP GmbH Leibniz Institute for Innovative Microelectronics Frankfurt (Oder) and the State Working Community of Chambers of Commerce and Industry in Brandenburg, represented by the Chamber of Commerce and Industry Cottbus.

The Mittelstand 4.0 Competence Center Cottbus is one of currently 26 centers of the nationwide initiative »Mittelstand 4.0 - Digital Production and Work Processes« under the umbrella of »Mittelstand-Digital« ('SMEs go digital').

Project duration:

01.11.2020 - 28.02.2023

01.11.2017 - 31.10.2020

What is Mittelstand-Digital?

Mittelstand-Digital informs small and medium-sized enterprises about the opportunities and challenges of digitization. Regional centers of excellence help the small retailer as well as the larger production site with expert knowledge, demonstration centers, networks for the exchange of experience and practical examples. The Federal Ministry for Economic Affairs and Energy enables the free use of all offers from Mittelstand-Digital. Further information can be found at www.mittelstand-digital.de.

Contact person:

Innovation Center Modern Industry Brandenburg (IMI)

Second period of funding

Set up as a central point of contact for small and medium-sized enterprises (SME) in Brandenburg, the Innovation Centre of Modern Industry (IMI) Brandenburg is the first point of contact when it comes to tackling the challenges of automation and digitization.

With a focus on the manufacturing industry, the institution, financed by the European Regional Development Fund (ERDF), accompanies process innovations and helps the responsible staff of the SMEs to understand and exploit the potential of digital technologies.

The support measures developed as part of the project serve the fields of innovation, technology and knowledge. Corresponding formats provide the necessary know-how, network, mediate the right partners and thus pave the way for the successful implementation of their own innovation projects. The following offers and services can be accessed free of charge by small and medium-sized companies in Brandenburg:

Innovation

In close cooperation and through intensive company support, process innovations are accompanied from the first idea through to implementation. The following individual services can be used free of charge:

- Maturity level determination: technological maturity level & benchmarking to the competition

- Potential analysis: relevance comparison & topic prioritization / specification

- Project support: Systematic & coordinated implementation preparation

- Partner acquisition: Search & networking with potential implementation partners

Technology

A model factory is available to illustrate the functional principles and possibilities of various technologies. Among other things, technological solutions from the following areas:

- Augmented & Virtual Reality

- Collaborative Robotics

- Automation with robots

- Digitally supported order processing

- Digitally supported work preparation & quality control

- Internet of Things & Cloud

- Predictive maintenance and repair

The demonstration and test environment is open to anyone interested and is welcome to visit. Extended sightseeing tours with the involvement of other technology partners are possible after appropriate arrangement.

Knowledge forum

In addition to imparting methodological and technological expertise at specialist and networking events, workshops and information tables at trade fairs and exhibitions, IMI Brandenburg provides information online under the heading "Knowledge Forum" about the range of events offered by relevant players in the region, specialist topics and success stories from SMEs, as well as current announcements and helpful information on digitization and automation topics.

Project Duration:

24 Months (2021 – 2022)

Contact Person

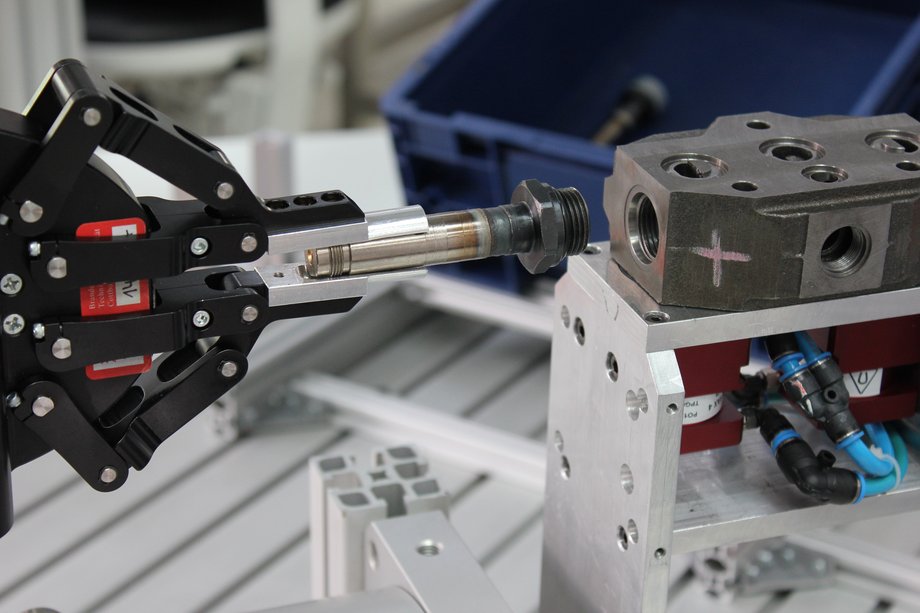

Cockpit 4.0

The joint project COCKPIT 4.0 researches innovative automation solutions for small series assembly in the aviation industry.

For this reason, prototypical solutions are developed and implemented in research demonstrators. Complex products with high quality demands on components and production processes as well as a high variety of variants characterize the tasks.

The use of novel assistance systems in communication between people and the work environment, cooperating, adaptive robot systems as well as qualification methods that can be adapted to the respective task are central subprojects that lead to a uniform system solution.

Human-centred penetration of real components in the assembly network based on computer-aided implementation techniques is enhanced by advanced digital twinning techniques. As result of this modern technology is the realization of digital twins.

Project Objectives

- Exploring the interface between humans and the work environment in small batch assembly with a focus on planning and programming functionalities

- Development of technology-assisted systems for complex components and assembly processes

- Preparation of procedural knowledge on assembly processes and return to upstream areas such as design and assembly planning

Technologies

- Methods of digital twinning in small batch assembly

- Selected methods of artificial intelligence, such as neural networks in the interface between human and work environment

- Human-robot cooperation in small batch assembly

Grant

The European Union grant the project COCKPIT 4.0 through the Innovation Bank of the State of Brandenburg within the framework of the program for the promotion of research, innovations and technologies (ProFit Brandenburg)

Project partners

The project partners are Rolls-Royce Germany Ltd & Co KG in Dahlewitz, the Brandenburg Technical University Cottbus-Senftenberg and the Fraunhofer Institute for Production Systems and Design Technology (IPK) Berlin

Project Duration

01.01.2018 – 31.12.2020, 3 Years

Contact Person

Carsten Wedemeyer

Innovation Center Modern Industry Brandenburg (IMI)

First period of funding

Project Innovation Center of Modern Industry (IMI) in Brandenburg

Set up as a central point of contact for small and medium-sized companies (SME) in Brandenburg, the Innovation Center »Modern Industry Brandenburg« supports innovations in the field of automation and digitization.

In addition to offering general information and awareness-raising activities, the facility also operates a model factory where can be demonstrated the possibilities of digitization and automation with examples to the entrepreneurs. In addition, in a four-step process, SME will be assistance in the development of approaches, the concretization of concepts and the implementation of resulting innovation projects.

In July 2015 was the IMI Brandenburg officially launched, located at the Chair of Automation Technology at the BTU Cottbus-Senftenberg, under the direction of Prof. Dr.-Ing. Ulrich Berger. A successful extension of the project, after a positive assessment of the first funding period will be further by the European Regional Development Fund (ERDF) financed.

During the first two and a half year project period, the IMI Brandenburg team was able to gather valuable experience from the close cooperation with the Brandenburg companies. Based on this, the already existing offer will be tailored to the specific needs of small and medium-sized businesses and give more practical relevance. In addition to the model factory at the IMI in Cottbus, further a locally distributed center created for the exchange of knowledge and experience. In the sense of a "company for company" concept, either implemented digitization and automation projects or projects, which are planned, could be viewed directly on site.

An additional focus based on the intensification and expansion of the existing cooperation and partner network. An establishing of an internet platform will support SME providing them with innovative and technical solutions.

Overall considered, aim all activities at making the subject of digitization and automation as well as all related offers, measures and services available across the area of Brandenburg.

Project Duration:

36 Months (01.01.2018 – 31.12.2020)

Contact Person

Innovation Center Modern Industry Brandenburg (IMI)

Within the framework of the project 'Innovation Center Modern Industry Brandenburg' a consulting center for small and medium sized enterprises in Brandenburg was created. The application of new technologies is demonstrated in a 'model factory' using realistic setups. Furthermore, entrepreneurs can learn about reference projects offering approaches and ideas for the improvement and optimization of their own processes. Through talks, discussion groups and workshops knowledge and Best-Practice-experiences about different areas related to Industrie 4.0, such as technologies, methods and processes, are imparted. Moreover, an analysis of the improvement potential regarding the actual state in the respective company is conducted based on a separate conversation and distinct aims are determined. Subsequently, an individual strategy for the implementation of the expansion, modernization or automation of the particular manufacturing processes is developed. In order to realize the required actions potential integration partners are introduced and cooperations and projects initiated. Also, the opportunity to get informed about possibilties for grants is provided.

Run-time

36 months (2015-2017)

Graduate School "dependable systems" (ZUSYS)

Dependable Hardware/Software Systems

Project ZUSYS

The Graduate School ZUSYS offers trainings for highly qualified professionals in the field of reliable HW/SW systems. The skills required in leading positions are generally not covered in traditional doctoral studies. Hence, the graduate student is able to gain specific knowledge in all basic technologies by taking part in tutorials, workshops, research projects and courses of ZUSYS. To ensure a high quality of education the BTU Cottbus-Senftenberg cooperates with the Universities of Liberec, Tallinn and Poznan.

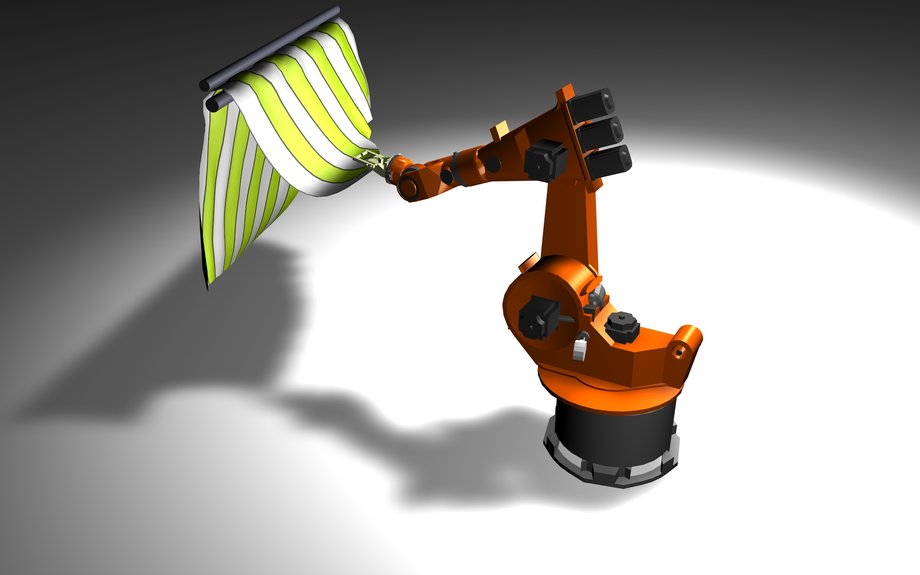

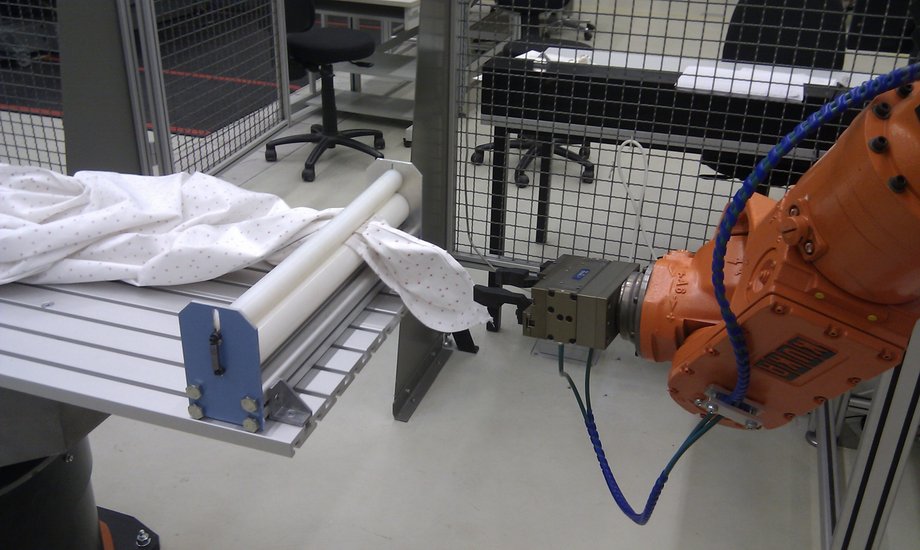

Laundry Robotics Co-Techno/RFID-System

Project Laundry Robotics

Development of a fully automated system for drying and smoothing of flat laundry

Research Projects

The development aims to significantly minimize the energy expenditure in the smoothing process by optimizing the combination between defined air and contact drying. At the same time productivity is to be increased by an automatic feeder the flat linen.

Tasks of the Chair

- Separating the washed laundry parts

- gripping and transferring the laundry article

- development of a defined hot air system

Run-time

(2014-2016)

Contact Person

COMET

"Plug and Produce" components and methods for adaptive control of robots in the factory of the future.

Projekt COMET (FP7-2010-NMP-258769)

Plug-and-produce COmponents and METhods for adaptive control of industrial robots enabling cost effective, high precision manufacturing in factories of the future

Research Projects

- Signature system for the characterization of industrial robots

- CAM-System for industrial robot application

- Adaptive Tracking System for Milling path tracking

- Highly dynamic compensation mechanism to increase the work piece surface quality

Tasks of the Chair

- Work Package management, technical coordination

- Modeling of robot behavior

- Analysis of the miling process

- Experimental validation of the results

Partner/Runtime

14 Partners, 30 Monath term (2010-2013)

eCUSTOM

System for web-based interaction for iteration of customer requirements in product design

Projekt eCUSTOM (EU-FP7-2010-NMP-ICT-FoF-260067)

A Web-based Collaboration System for Mass Customization

Research Projects

- User Adaptive Suspension System for the integation of customer requirements in product design (Open Innovation)

- Concept of production planning in the decentralized production system

- Ecological evaluation module for measuring the impact of different variants in production development on the environment

Tasks of the Chair

- Work Package management

- Development of a decetralized production planning module for optimizing distributed manufacturing process

- Construction of a multilayer data infrastructure for interoperabilty between different stakeholders

Partners/Runtime

11 Partners, 36 Month Term (2010-2013)

Project LASA

Investigations of the transition of Bachelor graduates to the professional environment

Project LASA

Transition of Bachelor graduates into the professional environment

Research Projects

- Study of the impact of the engineer gap between the academic environemt and the professional environment in Brandenburg

Tasks of the Chair

- Project coordinationand control

- Development of solution recommendations for universities based on survey results of the empirical survey

- Special considertaion of MINT graduates within 2 years after the graduation

(MINT: Mathematik-Informatik-Naturwissenschaften-Technik)

Partner/Runtime

Hochschule Lausitz, 21 Month Term (2011-2013)

Project AiF

Development of a fully automated system for drying and smoothing of flat layered laundry

Projekt AiF

Development of a fully automated system for drying and smoothing of flat layered laundry

Research Projects

The development aims to significantly minimize the energy expenditure by optimized combination between a defined air and contact drying during the process. At the same time productivity is to be increased by an automatic feeder of the flat linen.

Tasks of the Chair

- Separating the washed laudry articles

- Gripping and transferring the laudry articles

- Development of a defined Hot air system

Partners/Runtime

Vogler und Vogler GmbH, Waretex, WÄTAS, Kannegiesser,

27 Months Term (2011-2013)

Befund 4.0

This project aims to use innovative technologies, espacially digital media, to identify and diagnose technical parts of complex modules more easily. MTU Maintenance Berlin-Brandenburg and the Brandenburg University of Technology have therefor designed the project BEFUND 4.0.

Considering highly specialised working processes with very low fault tolerances different concepts for supporting the maintenance staff in different domains of their work are being developed. Additionally the concepts aim to reduce errors and their causes, increase process speed, precision and quality. Those improvements will result in lower costs for maintaining turbines.

The tasks of the BTU are focused on three topics:

- Technologies of image recognition are supposed to support the process of identifying components efficiantly. Additionally necessary documents for handling, inspecting and repairing turbines should be provided from the data system.

- Different approaches for the depiction of information in a suitable form for the processes at MTU are studied. Information must be presented in an understandable form. Therefor the most important information should be emphasized appropriatly.

- Digital transmission of defect information will enable MTU to save information about the process of the inspection as well as transferring those information to other employees in a comprehensible presentation. The digital procedure of the information transfer will be more accurate and efficiant. The technology will also improve the documentation in a components life cycle and reduce paper work.

Funding

The project Befund 4.0 is funded by the European Union with the programm „ProFit Brandenburg“.

Project partner

Project partner are the MTU Maintenance Berlin-Brandenburg GmbH (consortium leader) and the Brandenburg University of Technology.

Project's duration

01.01.2018 – 31.07.2018

Contact

Marc Gebauer

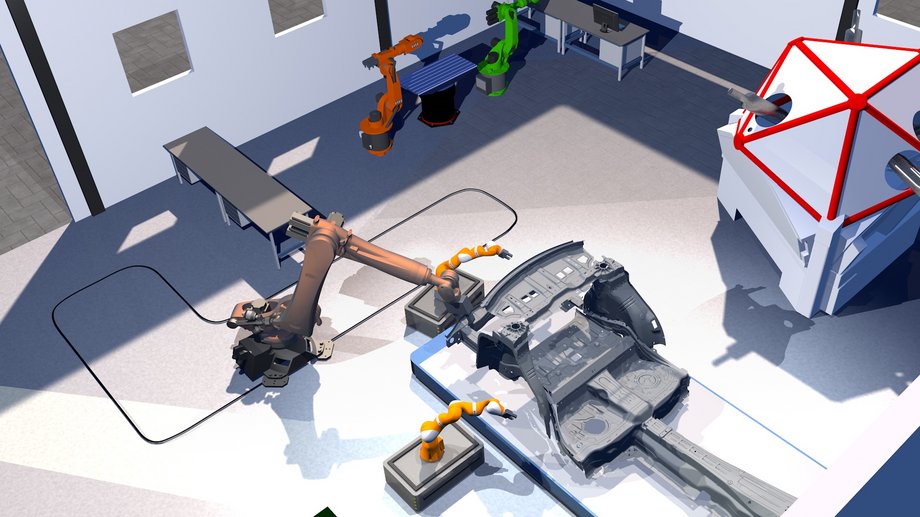

SmartBodySynergy

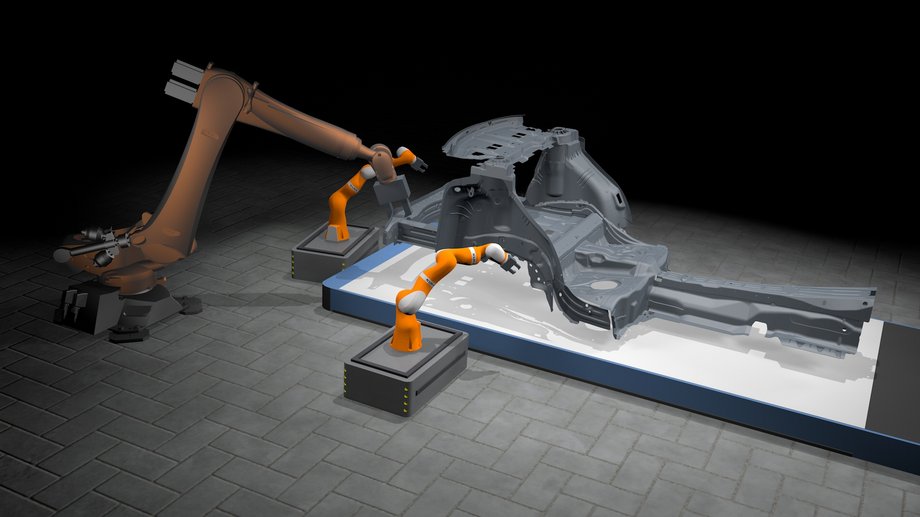

Smart body cells for a synergetic ramp-up of electrified vehicles

Development of modular bodyshell cells by an economic mix of flexibility and adaptability in a position to manufacture all derivatives of vehicle architecture and therefore maximum synergies with existing production

Research Projects

- flexible and versatile Powertrain plant and construction process

- plug&produce capable and geometry flexible grippung and clamping systems and replaceable Joint heads

- modulare, inline capable measuring and testing technology

- scalable quality strategies

Tasks of the chair

- Draft of CHR cell

- Development of a security concept for the demonstrator

- Hedging and acceptance of the CHR employees

- Exemplary adaptation of flex joint heads on demonstator

Partner/Run-time

6 Partners, 36 Month term (2016-2018)

Contact Person

Graduate School Dependable Cyber Physical Systems (DCPS)

as part of the DAAD program "Strategische Partnerschaften und thematische Netzwerke"

Projekt DCPS

The graduate school DCPS pursues a multidisciplinary approach enabling the postgraduate students to promote innovations in small and medium sized companies even beyond the limits of their own area of expertise. Therefore, a sound understanding of the overall system is essential, which is provided by interdisciplinary research areas and the cooporation with various universities.

Run-time

2013-2016

Contact Person

Graduate Research School "Lokale Produktion durch smarte Wertschöpfungsketten"

Currently, manufacturing procedures conducted locally are predominantly considered as Stand-Alone-processes. The central hypothesis of the granted Graduate Research School Cluster is, however, that the application of these manufacturing processes will increase significantly in order to compensate the lack of scalibility in mass production concerning the manufacturing of small batches, individual parts and individualized product variants. Thus, locally conducted manufacturing procedures have to be acknowledged as a part of new, 'smart' production and value chains.

Run-time

2016-2018

Contact Person

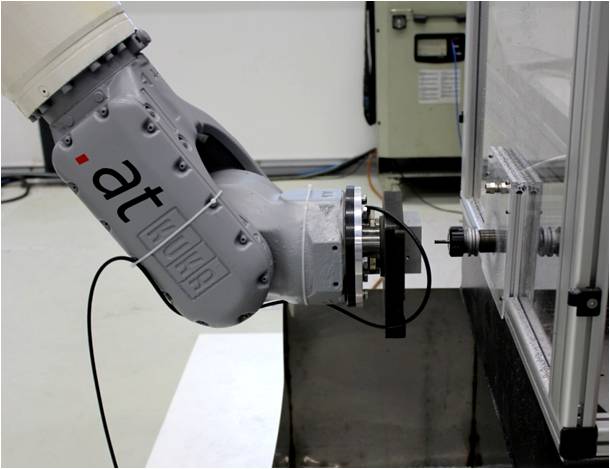

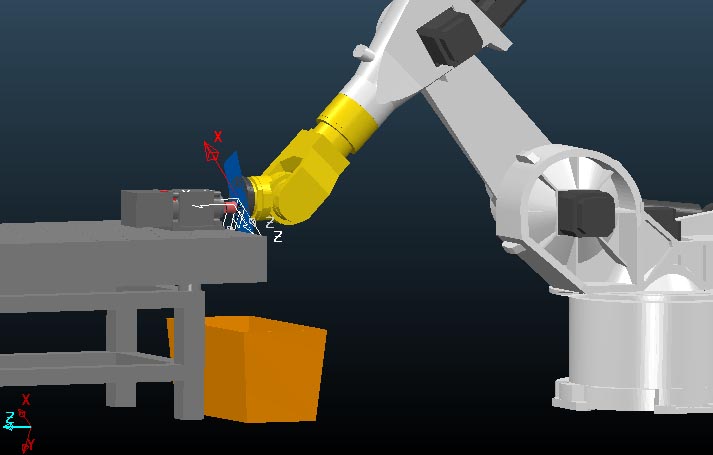

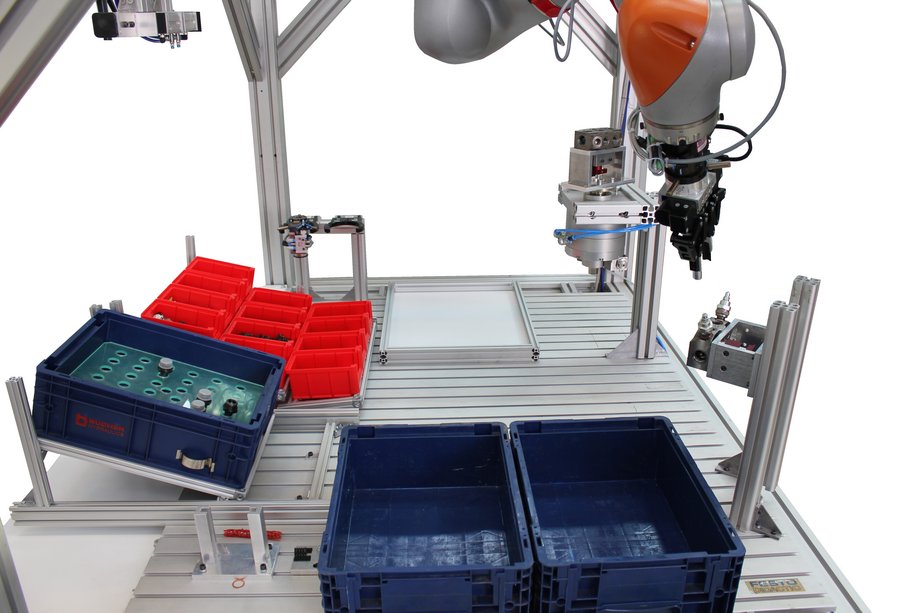

EU SMErobotics

Supplemental Demonstrator - HyLight: Assembly with sensitive compliant robot arms

Projekt EU SMErobotics (EU-FP7-2012)

Create SME-suitable robots that assist in managing uncertainty by symbiotic Human-Robot-Interaction (HRI) and embedded cognition going beyond flexibility by semantic integration

Research Projects

- Assembly of components with small tolerances

- process integrated quality control

- all-in-one solution for the separation of the various components

Tasks of the Chair

- Design and construction of Demonstation cell

- Development of a concept for onsite programming

- Develpoment of identification and localization system for the components

Partner/Run-time

3 Partners, 42 Months (2012-2016)

Contact Person

If you activate the integrated Youtube videos, you consent to the transfer of personal data to the provider and to the use of cookies to save the setting. Information of the BTU on data protection

BMBF KATHAROS

Prevation of Contamination by autonomous transport and handling robots in laundry systems

BMBF KATHAROS Project

Design of a novel service robot system for logistic processes in the field of application of industrial laundries

Research Projects

- Development of operating autonomously, linked transport, separating, sorting and Commission modules

- Investigation of adequate Identification Technologies

- Prototypical implementation of the concept and evaluation in real application scenarios

Tasks of the Chair

Development of mechanical components for handling, avionics, robotics for laundry sorting (dirty side) and transport robot

- Experimental validation of the demonstrators (in laboratory environment)

- Inclusion and integration of the separating and sorting robot in process and environment

Partners/Run-time

5 Partners, 36 Month term (2013-2016)

Contact Person

Other Projects

PCK Raffinerie Schwedt

Feasibility study for the automatic filling of tank cars

TSB Inpro

Study on the use of physics engines in the virtual planning of production processes

ZAB Waretex

Process simulation of managing laundry containers for automatic storage

HYMOLD (EU-FP6-COOP-CT-2006-032931)Development of a Hybrid Machine Tool Concept for Manufacturing of Freeform Surface Moulds

FUTURA (EU-FP6-2004-NMP-NI-4-026621)

Multi-Functional Materials and related Production Technologies integrated into the Automotive Industry of the Future

DFG-HBFG

Production laboratory with 5 -axis milling center