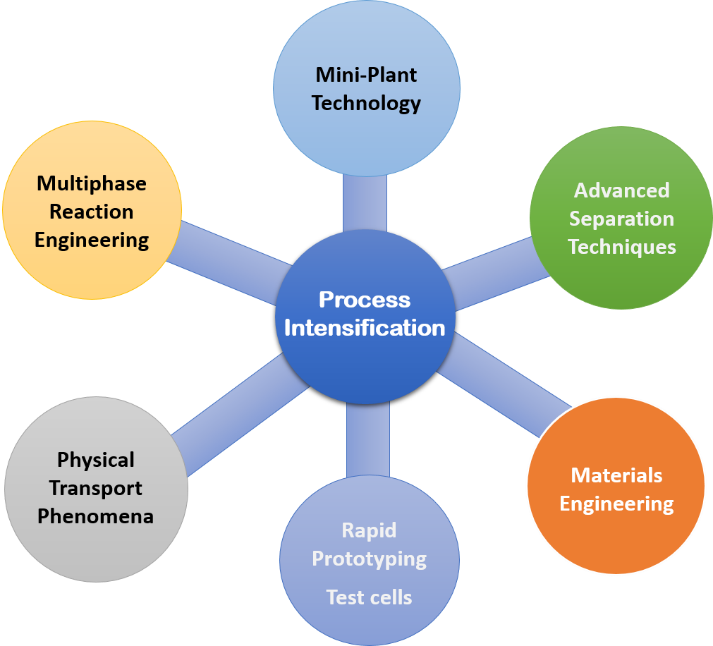

Process Intensification

The multidisciplinary research activities are concerned among others with the application of force field driven separation techniques (electrical, magnetic, ultrasound, microwave, light) while optimising the driving forces at every scale and maximising the specific surface area to which these forces apply. This will lead to the development of new improved concepts of processing methods and equipment for chemical and energy conversion systems. The activities will contribute towards understanding and modelling the dynamics of complex process systems as well as their systematic integration from functional units. The research on separation processes targets also advanced integrated technologies, such as reactive and hybrid separations in batch and continuous systems.

To test the performance and the applicability of results obtained under lab conditions, flexible modular and transportable mini-plants are designed, built and tested at the University. The use of this technology enables experimental investigations on a continuous mode, and thus allowing studies on the influence of recycle streams, catalyst performance, economic feasibility of the overall process and process stability in general. This systematic approach embodies undoubtedly a significant benefit which diminishes considerably the process development in the chemical and process Industry.

The multidisciplinary research activities propose to apply field driven separation techniques (electrical, magnetic, ultrasound, microwave, light) while optimizing the driving forces at every scale and maximizing the specific surface area to which these forces apply (Fig.). This will lead to the development of new and improved concepts of processing methods and equipment for chemical, biological, and energy conversion systems. The activities will also contribute towards understanding and modelling the dynamics of complex process systems as well as their systematic integration from functional units.