BMBF-VDI/VDE-Project "FORTUNE" Multi-sensor Condition Monitoring

Motivation

The industrial field encounters a major difficulty linked to the control of the condition of the machines. The machines can deteriorate without being noticed in time due to planned maintenance over long periods. This could cause loss of productivity. The machine status is often assessed on the basis of different sensory impressions, noises, vibrations, etc., the changes of which may not be noticeable individually or have little meaningfulness, but in combination are clear indicators. The real added value results primarily from the combination (sensor, information and data fusion), the information contained in the individual measurements. This vision could be implemented in order to achieve predictive maintenance.

Project description

Multi-sensor and information fusion to reduce wait cycles, i.e. for predictive maintenance, is a technology and a method of the future that lead to huge savings and better quality products in industrial production. New sensors and their combination are used for the first time to determine the status information of a system or its subsystems and to evaluate them. Bulk micromechanics enables cost-effective and energy-efficient sensor solutions for a wide range of frequencies. The special feature of the system will be the flexibility, robustness and energy-efficient connection of the sensors, which allow mobile and almost unlimited use in production machines. Due to the great flexibility of the system and the evaluation algorithms, a product sharing version of the system is possible, which means that even small and medium-sized enterprises can increase their maintenance and the efficiency of their processes at low cost.

Partners

Objectives

- Predictive maintenance for machine tools to optimize maintenance cycles

- Development of a measuring station for the characterization of sensor components

- Development of sensor components for machine diagnosis based on ultrasonic transducers

Challenges

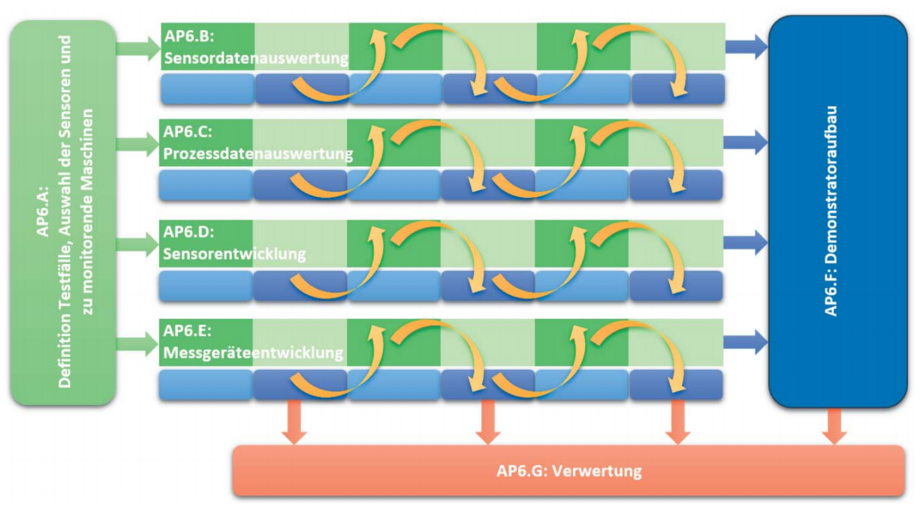

- Definition of test cases, selection of sensors and monitoring machines (A)

- Sensor data evaluation (B)

- Process data evaluation (C)

- Sensor development (D)

- Measuring device development (E)

- Demonstrator setup (F)

- Recovery (G)

For more details, please contact the following personnel: