Strong industry is the basis of Brandenburg's economic success. Small and medium sized companies in particular are faced with the challenge of building digital infrastructures in order to remain competitive. The Brandenburg Innovation Centre for Modern Industry is a new advice and consultation centre for companies that want to meet the challenges of increasingly integrated production and information technologies. The Chair of Automation Technology, lead by Prof. Dr.-Ing. Ulrich Berger, works together with regional partners in order to develop intelligent production units.

Central to the platform's work is the offer of 'innovation check-ups'. Scientists at the Innovation Centre examine the need for modernization in factories. The recommendations can then be implemented with the support of Brandenburg universities and other non-university institutions. In addition, companies can experience the possibilities of digitization and automation through examples demonstrated at a model factory in Cottbus.

The core of the work of this BTU – area of expertise is to adapt existing basic technologies to the specific changing demands of production and automation techniques for the purposes of industry 4.0. Scientists develop customized technological solutions for application-related issues – particularly for small and medium enterprises – in the following areas:

- Continuous digitization of business processes and supply chains

- Adaptability and flexibility of production and service by mechanization and automation

- Design of fast and secure data transmission

- Intelligent manufacturing cells and assistance systems

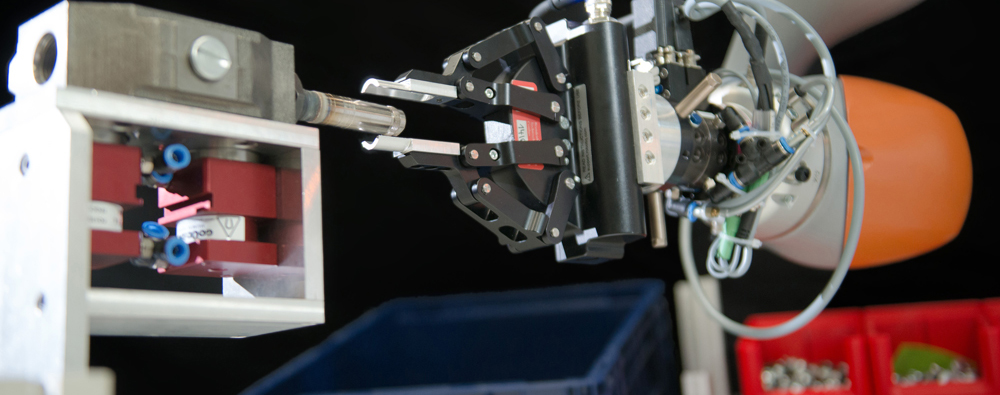

There are several laboratories, equipped with modern facilities and with industry-compliant technical specifications, which have machines and equipment for research and development work in the areas of control and automation technology, robot systems and numerically controlled machine tools. These form the basis for the development of digitization concepts for production and manufacturing, for the integration and networking of heterogeneous control systems for industrial automation and for the conception of innovative human-robot cooperation models.

Industry 4.0 – Digital Networking of Industrial Processes

From the idea through to production and delivery to the customer – digital networking of industrial processes allows the development of optimized standards in production and logistics. Industry 4.0 combines electrical engineering, information technology and mechanical and plant engineering in the Internet of Things. The intelligent networking of robot arms automates all production lines and conveyor belts transport goods over the visitors' heads.

The Federal Ministry of Education and Research (BMBF) and the Federal Ministry of Economic Affairs and Energy (BMWI) are keeping abreast of these developments and have launched the 'Future Project Industry 4.0' programme to provide subsidies for SMEs for implementation, development of standards, IT security and the upgrading of enterprises.