Current

Project Leader: Tim Franken

Time Period: 08.2022 - 07.2026

Website: Energie-Innovationszentrum

Goal:

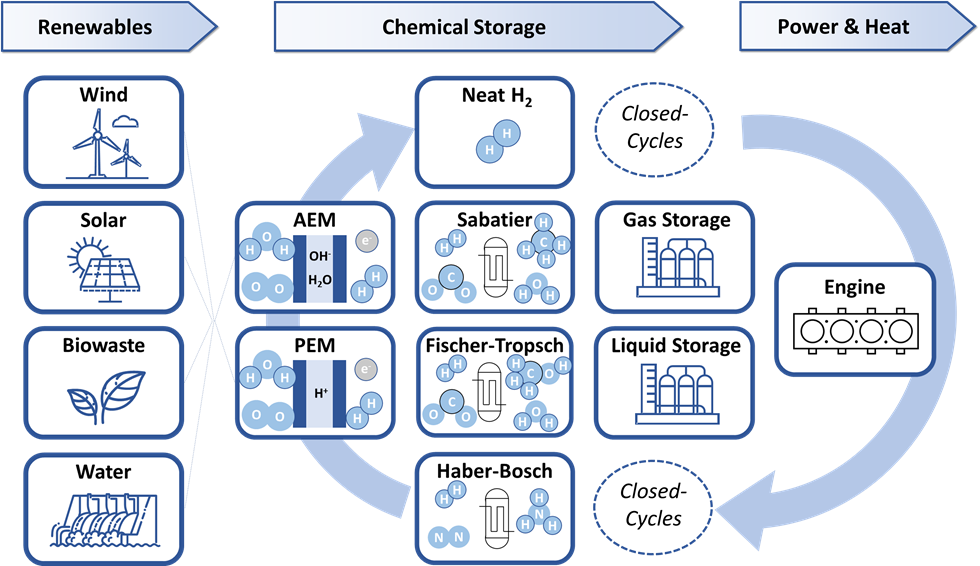

In the ESC Lab, the three levels for sector-coupled energy systems - heat, electricity and mobility - are to be mapped in a CO2-neutral cycle approach based on hydrogen. At all levels, the corresponding elements of the cycle approach will be developed and optimized, starting with hydrogen production at different pressure levels and process technologies according to the desired application (high pressure --> mobility, low pressure --> further synthesis). This is followed by the further processing of the hydrogen into the synthetic hydrocarbons methane and methanol, and their conversion back into electricity in the oxyfuel process for emission-free recycling of the exhaust gases, in the form of highly concentrated and pure CO2, into the material cycle. Each of the three levels is optimized and further developed for use in the cycle system in an understanding-based and simulation-supported development process in close exchange with the EIZ facilities EECON, DIVERSY, Scale-Up Lab, MoWes and SCL.

In the new ESC Lab to be set up, advanced measurement technology will be used to achieve a detailed characterization of the materials, components and process control as well as the optimization of their interaction. For this purpose, a novel model-based simulation and optimization platform will be developed based on detailed experimental analyses, which will enable extensive prototype validation in the early development period.

Project Leader: Hayat El Harrab

Time Period: 10.2022 - 09.2025

Website: BTU-BAM Graduiertenkolleg

Goal:

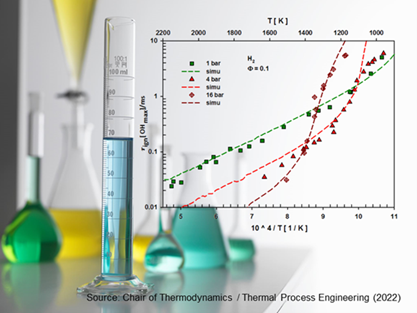

The operation of gas engines with green hydrogen from renewable energy sources is a future technology to achieve CO2-neutrality in the energy and transport sector. To increase the thermal efficiency of such piston engines the increase of compression ratio and charging of the intake air are applied. This leads to higher compression pressures and temperatures during the engine operation cycle. Further, to avoid galling and excess thermal stresses of the piston rings and cylinder surfaces, lubricating oils are necessary.

Due to the higher thermal auto-ignition propensity of engine oils compared to hydrogen, the oil can cause self-ignition under certain conditions, leading to low-speed pre-ignition (LSPI) phenomena. The LSPI creates strong pressure gradients within the combustion chamber, which can destroy the components, such as piston and valves. For example, low oil viscosities and high calcium content could enhance high pre-ignition rates. Hence, it is important to improve the knowledge of the impact of lubricant properties on LSPI in hydrogen engines.

In the joint research project between BTU Cottbus-Senftenberg, Chair of “Thermodynamics / Thermal Process Engineering”, and BAM Competence Centre “H2Safety@BAM”, the lubricating oil self-ignition process within hydrogen/air-mixtures will be investigated. Two approaches will be facilitated to investigate the self-ignition process: 1. An experimental investigation of the influence of lubricant oil properties under engine-relevant conditions, 2. A numerical investigation to understand the effects of physical and chemical processes on lubricant oil self-ignition. The results will contribute to the H2 safety for gas engine operation by proposing optimum lubricant properties to avoid LSPI, while ensuring appropriate lubrication.

Poject Leader: Prof. Dr.-Ing. Fabian Mauß

Time Period: 10.2021 - 10.2025

Website: WIRE

Goal:

By 2030, the bio-based economy is expected to have grown significantly in Europe. One of the pillars of this bioeconomy is the concept of BIOREFINERY, the sustainable processing of several kinds of waste and biomass into a spectrum of marketable products and energy. While in the past many research efforts have been conducted towards understanding, modelling and designing conversion processes that can sustain a true circular economy, this KNOWLEDGE IS QUITE FRAGMENTED and UNEVENLY DISTRIBUTED across Europe. Several countries lack proper policies and public engagement to endeavour the challenges ahead. HARMONIZATION must start on ROBUST KNOWLEDGE, and the ability to cover the WHOLE VALUECHAIN, from source materials up to the markeatable products… and that’s WIRE mission.

The WIRE COST Action broadly organizes into 4 KEY WORKING GROUPS (WG) that bring together experts from ACADEMIA, INDUSTRY and TECHNOLOGY TRANSFER organisations and range (1) Raw Materials, (2) Biorefinery Conversion Technologies, (3) Biorefinery Applications and (4) Communication and Dissemination. These WG will proactively contribute to (i) Promote circular economy, (ii) Promote bioenergy and bioeconomy, (iii) Promote Research & Innovation in the field (iv) Promote applied research towards biorefineries implementation (v) Promote EU-wide harmonisation of the scientific and technical approaches, thus facilitating ENGAGEMENT WITH POLICY-MAKERS and industry (vi) Pave the ground for a more effective link with the relevant INDUSTRY sectors and gathering their interest.

A series of meetings and events are planned to deliver the main aim of influencing positively the future landscape in Science and Technology in this important field of BIOREFINERIES.