Simulation and evaluation of joining processes

Application areas

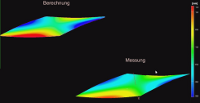

- Distortion prediction and minimization for large and complex weldments

- Microstructural changes (hardening) during welding and local heat treatment - prediction and prevention

- Residual stresses - prediction and evaluation

- Evaluation of cold crack resistance considering changes in microstructure, stresses and hydrogen content

- Prediction of property changes due to nitrogen redistribution

- Evaluation and design of joints under static, oscillating and dynamic loads

Simulation software

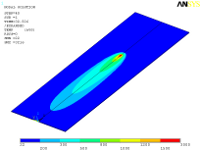

- Simulation tool for microstructure simulation for the general FE program ANSYS®.

- Routines for coupled process and structure simulation for the welding-specific FE program SYSWELD®.

- Cold crack tool for the weld-specific FE program SYSWELD®

- Fast analytical programs for the calculation of the temperature distribution during welding

- Own developments for gas diffusion during joining

- Software for the verification of the application according to DVS Merkblatt (No. not yet assigned): Download