Determination of material parameters

Fields of application

- Determination of temperature-dependent material characteristics in hot tensile tests for numerical simulation

- Characteristic values: proof stress, tensile strength, elongation at break

- Temperature range 20 - 1500 °C by controlled inductive heating

- Fast, joining process specific specimen heating

- Optimal temperature distribution in different specimen geometries by adapted induction coils

- Temperature and strain rate dependent material characteristics

HF generator AXIO 5/450 T for inductive specimen heating

- Power 5 kW

- Frequency range 50 - 450 kHz

- High efficiency due to optimum operating frequency

- Acquisition of all process parameters

High-temperature extensometer for strain measurement on the sample

- Measuring principle: inductive transformer

- Measuring length: 4 - 50 mm

- Measuring path: 10 mm

- Resolution: 0.1 mm - 130 mm

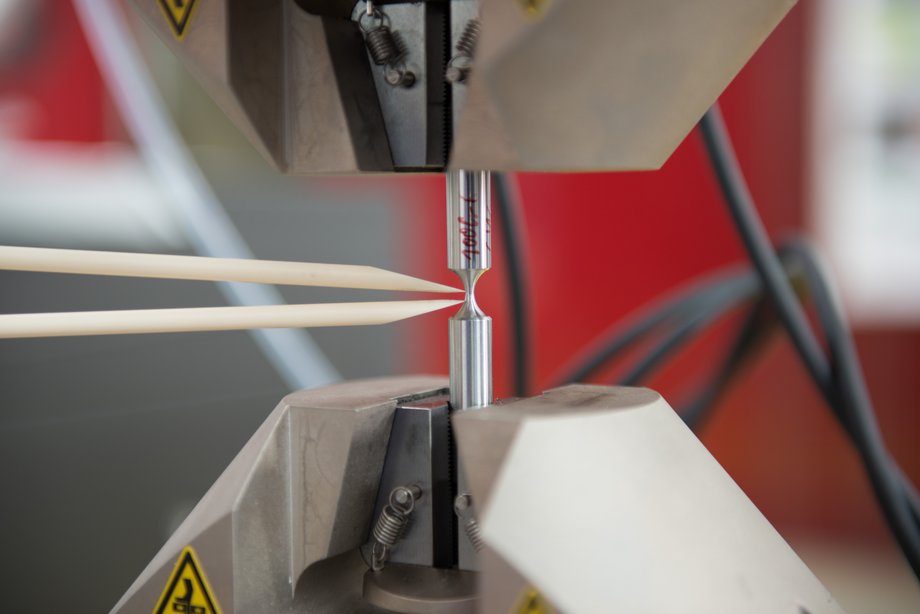

Drop tower CEAST 9350

- For notched bar impact test and puncture test

- As well as device for Tensil Test

- Max test speed 24m/s or 1800 Joule

Walter and Bei universal testing machine

- Servo-hydraulic universal testing machine

- With high resolution digital controller PCS5000 and testing software DION-Pro

- Max test force 150kN

Physical or experimental simulation of manufacturing processes

Fields of application

Processes

- Welding

- Forming

- Forming

- Forging

- Heat treatment

Material processes

- Melting and solidification

- Recrystallization

- Transformation behaviour and plasticity

- Precipitation behaviour

- Mechanical hardening

- Relaxation

- Hot cracking tendency

- Cold cracking tendency

Material testing

- Continuous and isothermal ZTA, ZTU, STAAZ charts

- Thermal expansion

- Stress-strain diagrams (tension/compression)

- Creep curves

- Thermal/mechanical fatigue

- Critical strain rate for hot cracking

Gleeble 3500

Features

- Complex system for physical simulation of thermo-mechanical processes as well as for quasi-static, dynamic and cyclic testing

- Synchronous digital control and acquisition of temperature, displacement, strain and force

- Exact time reproduction of thermal and mechanical loads on specimens and components

- Simulation corresponds to the real loading of the material during the manufacturing process or in operation

Technical data

- Temperature range 20 - 1700 °C

- Heating and cooling rates up to 10000 °C/s

- Maximum force 98 kN

- Maximum test speed 1000 mm/s

- Vacuum and controlled atmosphere

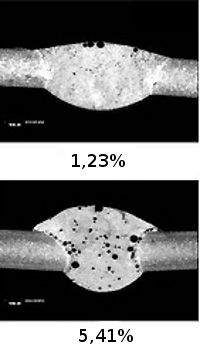

Hydrogen analysis

Areas of application

- Materials: steel, non-ferrous metals, e.g. Al and its alloys, Al die casting

- Welding consumables

- Metal powder

- Welds

- Coatings

- Customer specific analysis requirements

Hydrogen analyzer H-mat 225

- Melt extraction furnace with freely selectable analysis temperature up to

- Approx. 2500 °C for the determination of the total hydrogen content

- Infrared furnace for the determination of diffusible hydrogen by artificial ageing up to 900 °C

- Rapid analysis, automatic sequence

- Highly stable detection system with automatic measuring range selection

- Optical temperature measurement and control

- Measuring range: 0.1 - 1000 ppm

- Resolution: 0.01 ppm

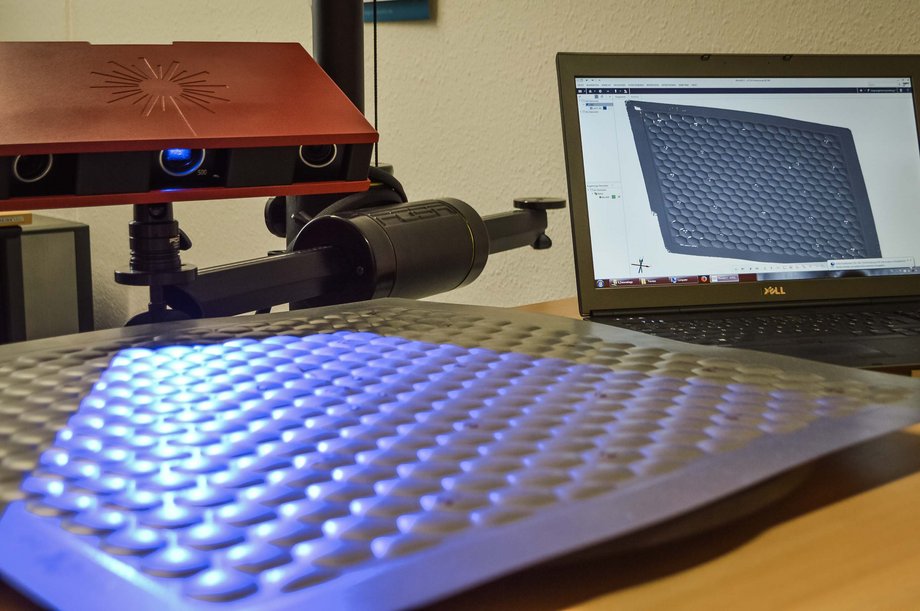

Three-dimensional distortion measurement

Application areas

- Deformation measurement on complex real components during the manufacturing process

- Manufacturing process, e.g. during joining

- Material testing

- Strength assessment

- Verification of FE simulations

- Analysis of the deformation behavior of homogeneous and inhomogeneous materials

- Materials, e.g. weld seams

- Strain calculation

Surface deformation measurement system ARAMIS®

- Surface with stochastic pattern

- Online image recording with digital 3D camera system

- Recordings in defined time intervals

- Offline evaluation or calculation of displacements

- Surface and graphical representation of the measurement results in the three-dimensional result space with high measurement point density. The graphical representation of the measurement results enables an optimal understanding of the component behaviour

Area hardness measurement

Areas of application

- Hardness scans of surfaces, e.g. welding seams

- Line scans

- Hardness of indentation, edge hardness and nitriding hardness

- Depth measurements according to DIN 50190

- Serial measurements

- Multiple measurements (several Eht, Rht, Nht or line measurements are carried out one after the other)

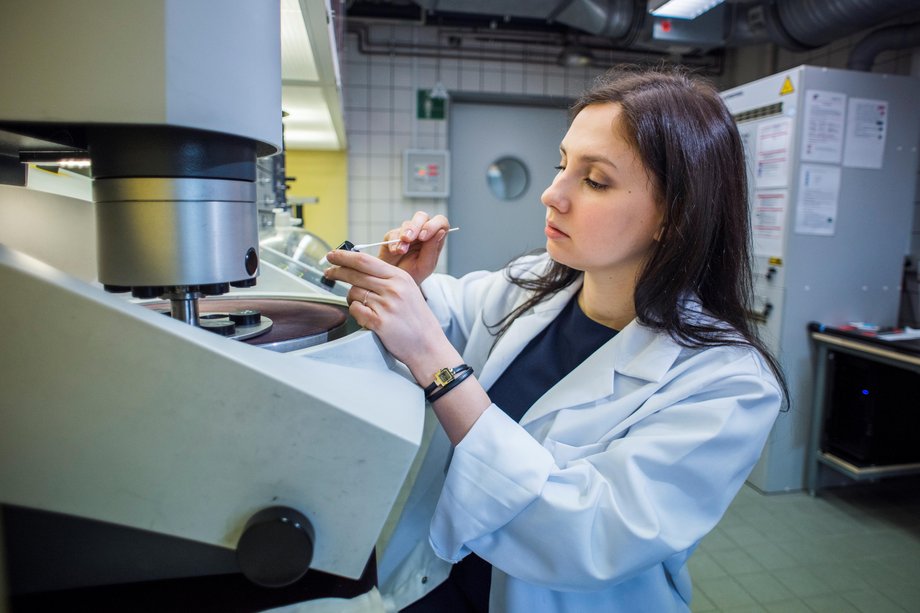

Hardness scanner UT 100

- Test load from HV 0.1 to HV 2

- Vickers hardness measurements according to DIN 50133

- Vickers hardness measurements with the UCI method according to VDI/VDE guideline 2616

- Hardness values in HV, HRC, HB or tensile strength (conversion according to DIN 50150)

- Positioning accuracy 0.01 mm

- Travel 270 x 290 x 130 mm

Area temperature measurement

Application areas

- Measurement of temperature fields during joining

- Temperature measurement

Thermography system "Vario CAM hr research

- Wavelength: 7.5 - 14 µm

- Measuring range: -40°C ... +1200°C

- Measuring accuracy: ±1.5K (0°C ... +100°C, otherwise ±2K or 2%)

High-speed systems

High speed camera

Photron Fastcam SA5 with Cavilux HF laser light

- 1024 x 1024 pixel up to 7.000 frames / second

- Up to 1.000.000 frames / second at reduced resolution

- 16GB memory