PROJECTS Other Applications

Perspectives in Stochastic Optimization and Applications

Abstract

In powder-bed additive manufacturing, a laser beam melts a thin layer of metallic powder, which solidifies during cooling and bonds to the already processed solid material. After finishing one layer, the surface is covered with a new thin powder layer, and the melting process iterates, until an entire three-dimensional object emerges. Due to the uneven heat distribution created by the laser beam, the part is usually under stress during the production which can lead to significant warping after cooling. Here, we study whether the order in which each layer is processed can be used to reduce warping in the finished product. As warping is difficult to model and predict, we use several approaches to approximate this effect, such as computing heat gradients and expansion through heat. These approximations are used to generate different objective functions for the mixed-integer linear program.

Main project results

- In a first step, we developed a numerical simulation of the SLM printing process. This model was supplemented with machine-learning techniques to evaluate the geometries of the printed shapes, as well as the properties of the cooling process.

- Building on these results we devised automated methods for optimizing the printing orders using mixed-integer programming.

- Furthermore, we designed new algorithms which can be used for automated quality control in an on-line setting.

- These results were tested in practical experiments by our project partners from engineering using state-of-the-art printing machines at the BTU Cottbus - Senftenberg.

References

| [1] | Bambach, M., Fügenschuh, A., Buhl, J., Jensch, F., & Schmidt, J. (2020). Mathematical modeling and optimization for powder-based additive manufacturing. Procedia Manufacturing, 47, 1159-1163. |

| [2] | Beisegel, J., Buhl, J., Israr, R., Schmidt, J., Bambach, M., & Fügenschuh, A. (2021). Mixed-integer programming for additive manufacturing. Submitted. |

| [3] | Bähr, M., Buhl, J., Radow, G., Schmidt, J., Bambach, M., Breuß, M., & Fügenschuh, A. (2021). Stable honeycomb structures and temperature based trajectory optimization for wire-arc additive manufacturing. Optimization and Engineering, 22(2), 913-974. |

| [4] | M. Breuß, J. Buhl, A. M. Yarahmadi, M. Bambach, P. Peter (2020). “A Simple Approach to Stiffness Enhancement of a Printable Shape by Hamilton-Jacobi Skeletonization”, Procedia Manufacturing 47, 1190-1196 |

| [5] | C. Hartmann, A. M. Yarahmadi, M. Breuß (2021). “Learning Laser Beam Trajectories for Optimization of Powder Bed Fusion Printing using a Multi-Phase Nucleation Model Coupled with Heat Simulation”. Submitted |

Duration

01/2020 - 12/2021, 24 months

Mission statement

To improve the production quality of powder-bed additive manufacturing using mathematical optimization tools to find optimal printing paths.

Researchers:

Armin Fügenschuh

BTU, Ingenieurmathematik und Numerik der Optimierung

T +49 (0)355 69 3127

fuegensc(at)b-tu.de

Carsten Hartmann

BTU, Stochastik und ihre Anwendungen

T +49 (0)355 69 4150

carsten.hartmann(at)b-tu.de

Michael Breuss

BTU, Angewandte Mathematik

T +49 (0)355 69 2904

breuss(at)b-tu.de

Projektleiter:

Prof. Dr.-Ing. Sebastian Härtel

BTU, Hybride Fertigung

Konrad-Wachsmann-Allee 17, 03046 Cottbus

haertel(at)b-tu.de

Dr. rer. nat. Jesse Beisegel

BTU, Ingenieurmathematik und Numerik der Optimierung

Platz der Deutschen Einheit 1, 03046 Cottbus

beisegel(at)b-tu.de

M.Sc. Johannes Schmidt

BTU, Ingenieurmathematik und Numerik der Optimierung

Platz der Deutschen Einheit 1, 03046 Cottbus

Johannes.Schmidt(at)b-tu.de

Dr. rer. nat. Ashkan Mansouri Yarahmadi

BTU, Ingenieurmathematik und Numerik der Optimierung

Platz der Deutschen Einheit 1, 03046 Cottbus

ashkan.mansouriYarahmadi(at)b-tu.de

M. Sc. Mahmoud Eltaher

BTU, Angewandte Mathematik

Platz der Deutschen Einheit 1, 03046 Cottbus

Mahmoud.Eltaher(at)b-tu.de

Dr.-Ing. Johannes Buhl

BTU, Hybride Fertigung

Konrad-Wachsmann-Allee 17, 03046 Cottbus

johannes.buhl(at)b-tu.de

Prof. Dr. Markus Bambach

Neue Fertigungstechnologien, ETH Zürich

Technoparkstrasse 1, 8005 Zürich, Schweiz

mbambach(at)ethz.ch

Funded by

EFRE

SENSOR-AKTOR-KI

Abstract

The aim of the project is to evaluate the use of customized sensor-related or actuator-related signal preprocessing using AI-based methods (focus: TinyAI/Embedded AI) using the example of IPMS sensors and actuators in combination with the IPMS RISC-V computing platform EMSA5. Existing IPMS sensors and actuators are to be analyzed and categorized with respect to local preprocessing. Likewise, suitable AI methods are to be defined, practically implemented and analyzed. Furthermore, an AI library for the RISC-V platform will be ported. Finally, the complete AI process chain for embedded systems can be implemented for selected sensors/actuators on RISC-V basis. Demonstrator setups will exemplify AI-based signal processing with real-time data from sensors and actuators.

Main project results

- Approach validated for embedded AI projects with IPMS sensors

Use cases: predictive maintenance and composition of liquids investigated - Tensorflow Lite library ported to EMSA5 RISC-V processor

- Implementation of demonstrator hardware and software

Duration

01/2021-12/2021, 12 months

Mission statement

Customized sensor and actuator related signal preprocessing using AI-based methods (TinyAI/Embedded AI) for RISC-V platforms

Researchers:

Sebastian Meyer

Fraunhofer IPMS

Institutsteil Integrated Silicon Systems ISS

T +49 (0)355 69 3210

sebastian.meyer(at)ipms.fraunhofer.de

Projektleiter

Andreas Weder

WMS

Maria-Reiche-Str. 2, 01109 Dresden

andreas.weder(at)ipms.fraunhofer.de

Funded by

FHG/IPMS (EFP)

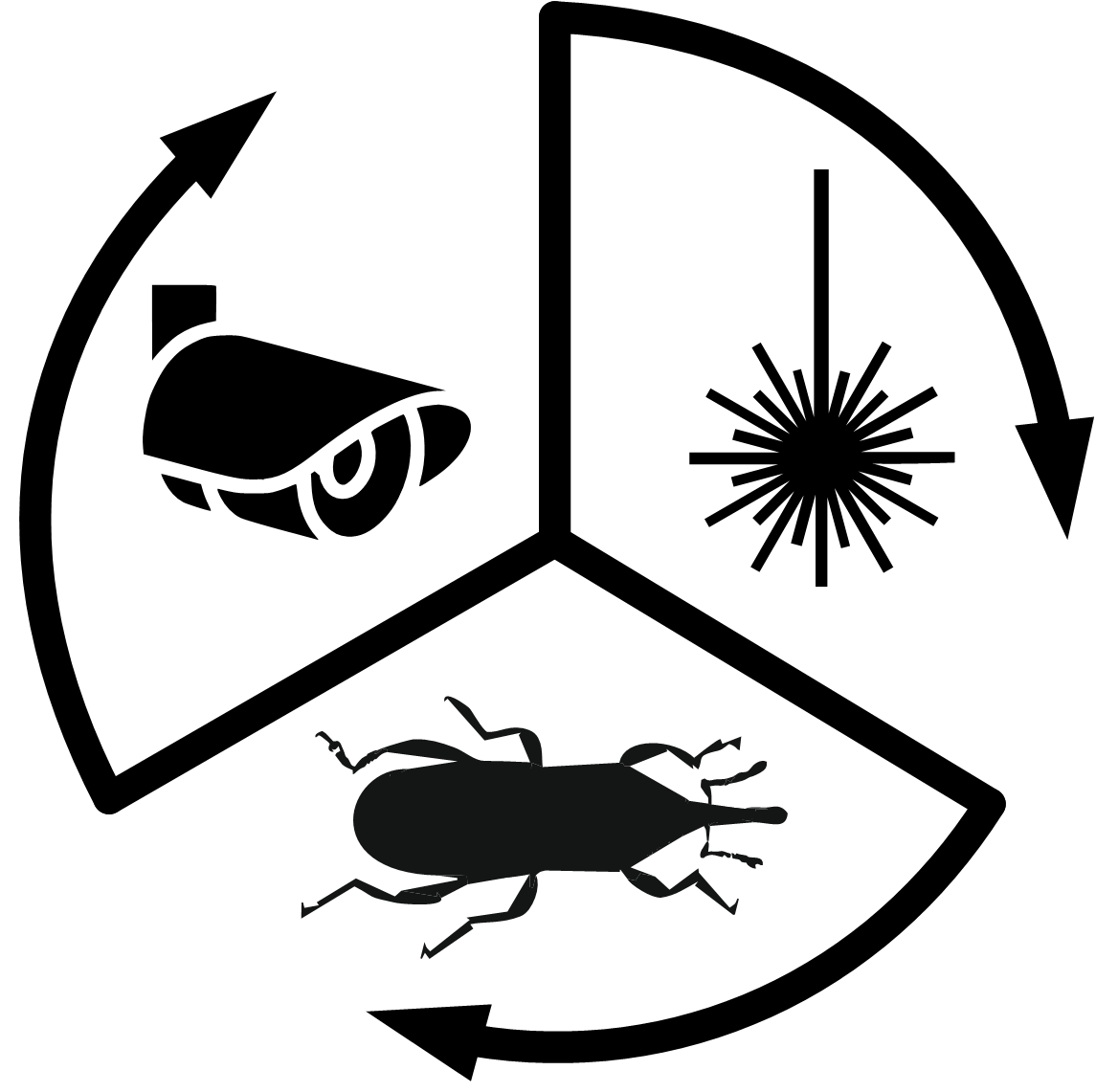

New methods of optical early detection and pest-free control of insects harmful to stocks using laser beams (insect laser)

Abstract

In this joint project, the optical early detection of insects that are harmful to stocks and their pest-free control with laser beams was investigated. To detect the pests, a camera image scanning a grain surface is evaluated by an artificial neural network. The coordinates of the detected pests are then transferred to a laser control unit, which moves a laser to the coordinates and kills the insects using a laser beam. For detection, a YOLOv4-Tiny network was trained to traverse the 2048 x 2048 pix camera image sequentially, at 512 x 512 pix. The subframes are evaluated at 25 fps, achieving a detection accuracy of 93%.

Main project results

- We have successfully developed an AI system to detect the grain weevil on a grain surface.

- Furthermore, a low-cost laser was determined to kill the insects without permanently affecting the stored material.

- Detected insects can be saved as sample images with coordinates, time and object class to build a database for further training data for the artificial neural network.

Duration

09/2017-8/2020, 36 months

Mission statement

Development of pattern recognition based on weak AI for insects harmful to stocks (grain weevils) and their subsequent pest-free control.

Researchers:

Christian Hentschel

BTU, Medientechnik

T +49 (0)355 69 2128

fg-medientechnik(at)b-tu.de

Projektleiter

Dr. Cornel Adler

Julius Kühn-Institut

Königin-Luise-Str. 19, 14195 Berlin

cornel.adler(at)julius-kuehn.de

Kirko Große

Lehrstuhl Medientechnik

Siemens-Halske-Ring 14, 03046 Cottbus

kirko.grosse(at)b-tu.de

Funded by

BMEL

AI Summarizer

Abstract

The AI summarizer is useful for summarizing longer texts to get a quick overview. Be it long legal texts, documentation or manuals, the possible applications are diverse.

The AI method used comes from unsupervised learning and is called "Unsupervised Multilingual Sentence Boundary Detection". This AI method is part of the so-called "Natural Language Processing (NLP)", i.e. the processing of natural language by a computer.

Main project results

- Public usable demonstrator for the application of the AI method NLP

References

| [1] | Kiss, T., & Strunk, J. (2006). Unsupervised multilingual sentence boundary detection. Computational linguistics, 32(4), 485-525. |

| [2] | Voekler, S. (2021). Machine-Learning-Verfahren in der Produktlinienoptimierung - Simulationsrechnungen und Robustheit, Doktorarbeit, BTU Cottbus – Senftenberg. |

Duration

05/2021 - 08/2021

Mission statement

To sensitize the public, especially SME, for the application of AI systems.

Researchers:

Projektleiter

Sascha Vökler

Mittelstand 4.0-Kompetenzzentrum Cottbus, LS Automatisierungstechnik

Siemens-Halske-Ring 14, 03046 Cottbus

sascha.voekler(at)b-tu.de

Funded by

BMWK

Quantum Information Access and Retrieval Theory

Abstract

QUARTZ (Quantum Information Access and Retrieval Theory) is an Innovative Training Network (ITN) that aims to educate its Early Stage Researchers to adopt a novel theoretically and empirically motivated approach to Information Access and Retrieval (IAR) based on the quantum mechanical framework that gives up the notions of unimodal features and classical ranking models disconnected from context.

The current state of the art of IAR is not sufficient to address the challenges of a dynamic, adaptive and context-aware user-machine interaction and to make a major breakthrough in the overall effectiveness of retrieval systems, and that a genuine theoretical breakthrough is on the contrary necessary.

Main project results

Website

Duration

01/2017-12/2021

Mission statement

To devise a ... / To build aWe believe that this breakthrough can be provided by quantum theory which can integrate abstract vector spaces, probab ...

Researchers:

Ingo Schmitt

BTU, Datenbank- und Informationssysteme

T +49 (0)355 69 2039

ingo.schmitt(at)b-tu.de

Projektleiter

Massimo Melucci

University of Padova, Italy

Via Gradenigo 6/b 35131 - Padova Italy

massimo.melucci@unipd.it

externe Partner

Christina Lioma

University of Copenhagen, Denmark, Department of Computer Science

Nørregade 10, PO Box 2177 - 1017 Copenhagen K

c.lioma(at)di.ku.dk

Dawei Song

The Open University, The United Kingdom, Department of Computing and Communications

Walton Hall, Milton Keynes, MK7 6AA, UK

dwsong(at)tju.edu.cn

Funded by

Horizon 2020, European Training Networks (MSCA-ITN-ETN)

*completed