New Staff Member

Cottbus, July 2nd, 2024

Hello! My name is Nelu Sprater. I hold a university degree (Dipl.-Ing.) in Iron and Steel Metallurgy (TU Bergakademie Freiberg, 2015-2020). Additionally, I have studied Mathematics (2014-2015) and Technical Cybernetics and Systems Theory (2020-2024) at TU Ilmenau. My areas of interest include the modeling, simulation, optimization, control, and automation of technical processes, particularly in the steel industry, thermal process engineering, and electrical energy technology. I have also delved deeply into the analysis and numerical methods of partial differential equations as well as the mathematical systems theory of infinite-dimensional systems. To ensure a high practical relevance of my work, I conducted the majority of my research projects in the industry. It has always been important to me to connect mathematically sound theory with the actual applicability of the results. In this context, I recently focused intensively on system identification, which involves estimating unknown system parameters using data-driven methods. As of July 1, 2024, I have taken up a position as an Academic Staff Member in the Chair of Thermal Energy Technology at BTU. Here, I will be involved in process simulation of electrolysis plants for hydrogen production. This field allows me to optimally combine my acquired knowledge in process engineering, physical chemistry, electrical engineering, materials science, numerical simulation, and cybernetics. Furthermore, hydrogen will continue to gain immense importance in energy technology and the steel industry, which is undergoing the greatest transformation in its history. In addition to my scientific activities, I will also take on teaching responsibilities in the department and will offer the course on Energy Conversion in the winter semester of 2024/25.

New BMDV Project POWER-2-RESCUE

Cottbus, July 1st, 2024

With the participation of BTU, the new BMDV project POWER-2-RESCUE has been launched today. The project, led by the Björn Steiger Foundation and in collaboration with the Brandenburg Institute for Society and Security, examines the impact of the mobility transition on emergency services, fire departments, and disaster management in the 'Health Model Region Lusatia'. This initiative is driven by the impending end of the approval of internal combustion engines in the EU, necessitating the introduction of alternative propulsion technologies for authorities and organizations with security tasks (BOS). This requires new decision-making bases for municipalities and districts, as well as early information for manufacturers about future investment needs. As part of the project, a feasibility study will be conducted to explore approaches for environmentally friendly propulsion systems and the necessary refueling and charging infrastructure for emergency vehicles used by fire departments, emergency services, and disaster management. The foundation will be data and scientific forecasts provided by end-users to develop practical solutions. Two expert workshops with end-users will be held to develop practical and innovation-oriented content, identify needs, and propose solutions. This will form the basis for a subsequent exploratory project. A literature review will support the socio-economic contextualization of the topic, and the findings will be published in a study. Finally, the results will be discussed and evaluated in a workshop with manufacturers and equipment suppliers. The project focuses particularly on the Lusatia region, which faces significant economic restructuring due to the planned phase-out of lignite by 2038. At the same time, the reform of the hospital structure and emergency care requires an adaptation of regional infrastructures to ensure reliable public services. POWER-2-RESCUE is the first nationwide project to comprehensively and openly address the future operational capability of BOS institutions in the face of the energy transition. It provides early decision-making aids for investments in the emergency services of the future.

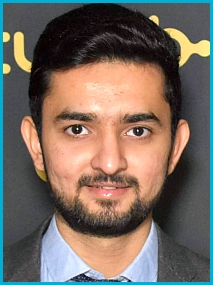

New Staff Member

Cottbus, April 16th, 2024

Greetings! My name is Harshit Sanjaybhai Dhanani, and I recently earned a master's degree in Power Engineering from BTU Cottbus-Senftenberg. Since June 2022, I have been employed as a student research assistant at BTU Cottbus, specifically with the Chair of Thermal Energy Technology. Recently, I successfully completed my master's thesis, which involved modeling, validating, and simulating a PEM water electrolysis system that utilizes renewable energy sources. The Ebsilon Professional Software was used for this purpose. As of April 2024, I am now an academic staff member at BTU at the Chair of Thermal Energy Technology. I am involved in two ongoing research projects, namely H2BAR and CLEANHYPRO. I am committed to acquiring and exchanging further knowledge and expertise in the field of hydrogen, and to achieving experimental and simulation-based progress in implementing sustainable hydrogen-based energy solutions that contribute to a clean environment. I am particularly looking forward to sharing ideas and learning from the existing team participating in the projects assigned to me.

Defence of Harshit Dhanani's master's thesis on March 22, 2024

Cottbus, March 7th, 2024

The Chair of Thermal Energy Technology invites you to present the following master's thesis:

Student: Harshit Dhanani

Topic: "Modeling, Validation, and Simulation of the Proton Exchange Membrane Water Electrolysis (PEMWE) System with Renewable Energy Sources Using the Ebsilon Professional Software"

Responsible professor: Prof. Dr. Lars Röntzsch

Scientific supervisor: Krunal Thummar, M.Sc.

Location: Building FZ3E, Room 0.26

Date and time: Friday, March 22nd, 2024, at 11:00

The defence will be conducted in English.

New Staff Member

Cottbus, December 4th, 2023

Hello! My name is Sayantan Jana and I have recently earned a doctoral degree in Mechanical Engineering from the Indian Institute of Technology Guwahati. My Ph.D. Thesis work was focused on the development of metal hydride based hydrogen storage and cooling systems for off-grid applications. As of 4th December 2023, I joined the department of Thermal Energy Technology at BTU as an academic staff member. In this role, my responsibilities encompass a dual commitment to teaching and research. I will be involved in teaching masters’ degree courses like Hydrogen and Fuel Cells, Power Plant Technology etc. As far as research is concerned, my primary focus is to design and develop novel solid-state hydrogen carrier systems suiting the requirement of simultaneously integrating with fuel cells and electrolysers. Apart from hydrogen storage, I also aim to develop efficient, low-cost hydrogen purification and compression systems with metal hydrides.

State Secretary Michael Kellner Explores the Energy Innovation Center and Emphasizes the Significance of Hydrogen

On October 17, 2023, State Secretary Michael Kellner from the Federal Ministry for Economic Affairs and Climate Action (BMWK) paid a visit to the Energy Innovation Center (EIZ). The central theme of his visit was the successful transformation of the entire region and the strategies to enhance public acceptance of renewable energy.

During his stay, State Secretary Kellner gained insights into the work of the EIZ team at BTU Cottbus-Senftenberg. He was warmly welcomed by BTU President Prof. Dr. Gesine Grande, Prof. Dr.-Ing. Johannes Schiffer, the project leader of the EIZ, and Dr. Jakob Pohlisch, the operational project manager of the EIZ. After a brief introduction to the EIZ, the delegation proceeded to the research laboratories, where two of them showcased their work.

State Secretary Kellner was particularly impressed by the research findings presented by Dr. Shiva Kumar Sampangi in the ESC-Lab of the Hydrogen Research Center, which is under the supervision of Prof. Dr. Lars Röntzsch in the field of Thermal Energy Technology. In his remarks, Kellner underscored the high relevance of this project and BTU's role in the successful regional transformation, extending its importance beyond the immediate region. Thus, the State Secretary's keen interest in hydrogen and its applications takes center stage in this visit to the Energy Innovation Center.

New Staff Member

Cottbus, October 9th, 2023

Greetings, I'm Hesham Mahfouz, and I'm excited to introduce myself as a research scientist at the Department of Thermal Energy Technology, where I've been engaged in the EU project PEACE (Pressurized Efficient Alkaline Electrolyser) since October 2023. The primary objective of the PEACE project is to advance the development of an efficient alkaline electrolysis system (AEL) that excels under high-pressure conditions, specifically targeting an operational pressure of up to 90 bar. My role encompasses a range of responsibilities, including optimizing the balance of plant, assembling, operating, and demonstrating this innovative technology to validate its ability to meet its performance benchmarks.

New EU Project CLEANHYPRO

Cottbus, October 1st, 2023

With the participation of BTU, the new EU project CLEANHYPRO (Open Innovation Test Bed for Electrolysis Materials for Clean Hydrogen Production) has been launched today. CLEANHYPRO brings together some of the most esteemed research institutions in Europe in the field of water electrolysis. CLEANHYPRO aims to provide several key resources:

Production Pilots: The project offers access to promising and groundbreaking production pilots.

Advanced Characterization Techniques and Modeling: Advanced techniques and modeling capabilities are available for characterization.

Non-Technical Services: In addition to technical resources, CLEANHYPRO also offers non-technical services.

This Open Innovation Test Bed serves as a central hub for stakeholders and has the potential to involve companies on an international scale. Within the scope of CLEANHYPRO, various innovative materials and key components of the four main electrolysis technologies are covered. CLEANHYPRO creates a single entry point for industrial partners, especially SMEs, reducing investment costs and minimizing risks associated with technology transfer. It also provides opportunities for material and component demonstrations (TRL7) to accelerate the market entry of these new products. In Showcase #1, dedicated to alkaline electrolysis, BTU provides test capabilities for relevant industrial partners to evaluate novel electrode materials, separators, or cell designs for pressurized operation.

Summer School ENGAGE

Salvador, Bahia, August 2023

Professor Lars Röntzsch was invited to deliver lectures on "Hydrogen for Energy Technology" during the ENGAGE Summer School ("Engineering Low-Carbon Processes and Emitting Technologies"), which took place at the prestigious Universidade Federal da Bahia in Salvador. This collaboration contributes to further enhancing educational and cooperative ties between Brazil and Germany, with a particular focus on promoting the exchange of doctoral and postdoctoral students.

Perspective Forum "Hydrogen"

Cottbus, September 2023

At BTU, young individuals had the opportunity to explore the foundations of a green hydrogen economy during a Perspective Forum organized by "Jugend forscht" (Youth Science). Through workshops and discussions with hydrogen experts from the business, scientific, and hydrogen research network sectors, they gained insights into research and development. This event, initiated by "Jugend-forscht" alumni, received support from the BMWK (Federal Ministry for Economic Affairs and Climate Action). Led by Professor Lars Röntzsch, the forum aimed to inspire young researchers and ignite their enthusiasm for studies in renewable energy and hydrogen technology.

New Staff Member

Cottbus, July 13th, 2023

Greetings! I am Dr. Shiva Kumar Sampangi. I completed my doctoral (Ph.D.) degree in the field of hydrogen production through water electrolysis in 2020. After my Ph.D., I gained three years of research experience as a postdoctoral researcher and industrial experience as a Deputy Manager-Team Lead for Hydrogen projects. Starting on July 13th 2023, I have been working as a Postdoctoral Researcher and Project Manager at the Department of Thermal Energy Technology and the Hydrogen Research Centre, BTU, in the EIZ-ESEW Project. In this project, my responsibilities include designing and developing single-cell and 5-10 cell stacks of AEM water electrolyzers with an active area of up to 360 cm2, operating at high temperature and pressure. Additionally, I will be designing and developing novel non-precious metal-free catalyst materials and membrane electrode assemblies (MEAs) for anion exchange membrane electrolysis (AEMEL). These materials will be investigated to contribute significantly to the technology's development, from laboratory scale to industrial implementation. Furthermore, my research work involves investigating and optimizing the physical and electrochemical properties of the electrolyzer system. This includes determining optimal design parameters for long-term stability, as well as operating parameters at higher pressure and current densities.