Equipment

The Chair of Polymer-based Lightweight Construction (PbL) has the following equipment available for its research work:

- Machine technology

- Additive manufacturing

- Measuring and testing technology

- Fibre composite laboratory

- Software

- ZenaLeb

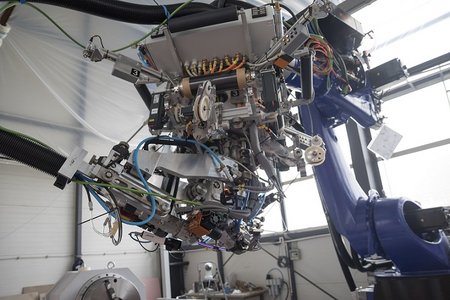

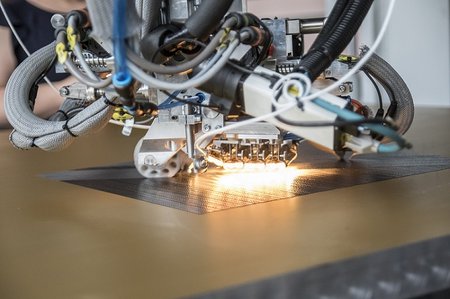

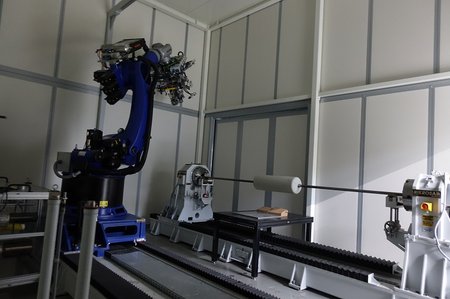

Automated Fibre Placement (AFP) annex

Mikrosam A.D. MRFP - 4T64/2000.2000

- Processing of prepreg slit tapes (thermosets & thermoplastics)

- Flexibility in production → fibre selection, complex geometries

- High fibre volume content (> 60%)

- Laying head with 4 x ¼ " slit tapes

- Tape thickness: 0.1 - 0.25 mm

- Kuka Fortec KR-480 articulated arm robot

- 2 m winding axis, 600 kg load capacity

- Clamping area: 1500 x 1500 mm

Prepreg slitter and parallel rewinding system

Mikrosam A.D. MSR-300D-1P

Parameters of the prepreg slitter:

- min. width of the UD prepreg: 25.4 mm

- Max. width of the UD prepreg: 300 mm

- Max. weight of the UD prepreg: 30 kg

- Inner diameter of the UD prepreg: 152 mm

- Max. outer diameter of the UD prepreg: 500 mm

- Speed of the process: 30 m/min

Parameters of the rewinding system:

- min. width of the unwinding material: 6.35 mm

- max. width of the unwinding material: 12.7 mm

- max. outer diameter of the unwinding material: 420 mm

- max. weight of the UD prepreg: 5 kg

- max. length of the coil core: 120 mm

- Core diameter of the winding spools: 76.2 mm

- Speed of the process: 50 m /min

Fibre winding system

Mikrosam A.D. MAW 20 LS4/1

Flexible fibre winding system for the production of fibre composite pressure vessels and other rotationally symmetrical components using the wet winding process.

- Number of controlled axes: 5

- Maximum product length: 3000 mm

- Maximum clamping length: 3,500 mm

- Maximum spindle weight capacity: 300 kg

- Spindle axis speed range: 0 - 120 rpm

- Slide axis speed range: 0 - 60 m/min

- Speed range of the cross slide axis: 0 - 30 m/min

- Eye rotation stroke range: +/- 180°

- Eye rotation speed: 0 - 120 RPM

Robo Moulding Annex

Autoclave

Italmatic Presse e Stampi S.r.l.

- Working pressure: up to 15 bar

- Max. operating temperature: 250 °C

- Usable inner diameter: 1050 mm

- Usable inner length: 2000 mm

- Vacuum connections: 4 + 4

- Thermocouples (fixed to the component or moulding tool): 6

- Max. load mass (FKV + aluminium): 30 kg + 70 kg

- Heating gradient (with max. load mass): 3 °C/min

- Cooling gradient (with max. load mass): 3 °C/min

Turn-mill centre

DMG Mori, NTX 2000 2nd Generation

- Main/counter spindle 5k rpm

- B-axis, 12k rpm

- Tool turret, 12k rpm

- 6 axes full machining

- Turning diameter (max): 670 mm

- Installation space (X/Y): 1562, 675 mm

- Control: Celos Mapps Fanuc F31iB5

5-axis simultaneous milling machine

Hermle C52 GEN2

- Installation space (X/Y/Z) 1m / 1.1m / 0.75m

- Milling spindle: 18k rpm / HSK

- Control: Siemens SINUMERIK ONE

Injection moulding machine

KraussMaffei Multinject CXZ 65-180/55

- 2-component injection moulding machine

- 2 plasticising units

- 650 kN clamping force

- 13 - 105 g shot weight

- max. barrel heating temperature: 375 °C

- max. mould size: 450 x 700 x 600 mm

Injection moulding machine

Arburg Allrounder 370 S multi-component injection moulding machine

- 2-component injection moulding machine

- 2 plasticising units

- 700 kN clamping force

- Horizontal injection unit 290 with a 35 mm screw, up to 132 g shot weight

- Vertical injection unit 70 with a 22 mm screw, 31 g shot weight

- max. barrel heating temperature: 375 °C

- Max. mould size: 370 x 520 x 450 mm

Hot press

Rucks KV275.09

- Pressing force: 100 - 1,000 kN

- Pressing surface: 600 x 600 mm

- Maximum temperature: 450 °C

RTM annex

WOLFANGEL iJect touch EP

- mobile PLC-controlled injection system

- Discharge rate: max. 1 kg/min

- Dosing ratio: 100:18 - 100:40

Flat film line

Dr Collin 3-roller chill roll type CR 136 - 230 S

- 90° swivelling roller group

- Speed range: 0.5 - 5 m/min

- Roller width: 230 mm

- Temperature control: max. 90 °C

- Cooling capacity: 24 kW

Prepreg system

2 TEACH-LINE extruders type E20T

- Processing of PA6 and PP

- Throughput: max. 3.5 kg/h

- Stroke adjustment: 0° - 30

2 wide slot dies

- Width: 120 mm

- Thickness: 0.1 - 0.4 mm

- IR preheating

Extrusion line

Boston Matthews

Parameters of the extruder:

- Screw diameter: 60 mm

- L:D ratio: 5:1

- Max. temperature: 380 °C

Parameters of the cooling section:

- Length: 5 m

- Capacity: 4.4 l/min

- Circulation system

Precision lathe

Proxxon Micromot PD 250/E

- Spindle speed (min.): 300 rpm

- Spindle speed (max.): 3000 rpm

- Centre width: 250 mm

- Centre height: 70 mm

- Automatic feed optionally 0.05 or 0.1 mm/rev

Sandblasting cabin

UNICRAFT SSK 2.5

- Internal dimensions: 945 x 605 x 605 mm

- Working cabin volume: 310 litres

- Air consumption 200 - 350 l/min

- Working pressure 4.1 - 8.0 bar

- Blasting abrasive grain size: 0.12 - 0.25 mm

- Glass bead blasting media, corundum blasting media, silicon carbide, plastic blasting media and much more.

Circular panel saw

MAIKO KKS 1300

- max. saw length: 1310 mm

- Angularity acc. DIN ISO 2768-1: +/- 0° 2` (corresponds to +/- 0.1mm / 30 mm)

- Straightness acc. DIN ISO 2768-1: +/- 0.1 mm / 1000 mm

- Parallelism according to DIN ISO 2768-1: +/- 0.1 mm / 1000 mm

- Saw blades for CFRP and metals

- Chip box

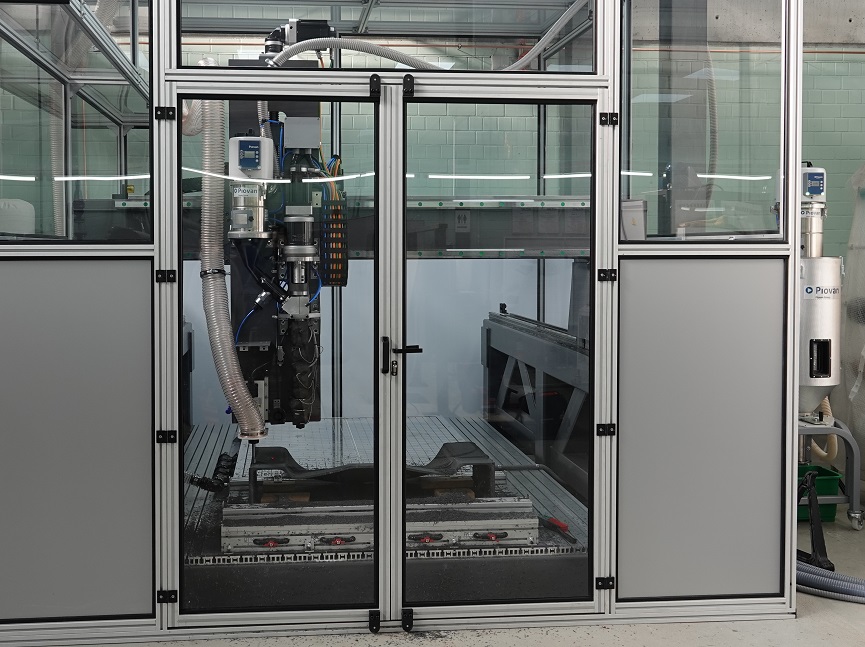

Portal milling machine

BZT-PFE1010-PX

- Repeat accuracy: approx. +/- 0.01 mm

- Clamping surface: x=1000 mm y=1495 mm

- Traverse paths: x=995 mm y=1150 mm and z=250 mm

- Vacuum clamping table: 1000 mm x 1000 mm clamping surface

High-temperature oven

Nabertherm LHTCT 01/16

- Internal dimensions (WxDxH): 110 x 120 x 120 mm

- Volume: 1.5 litres

- Max. temperature: 1550 °C

- Minutes to Tmax: 40

Tube furnace

Carbolite CTF 17/300

- max. working tube diameter: 90 mm

- Heated length: 300 mm

- max. temperature: 1700 °C

- max. power: 4125 W

- Holding power: 2500 W

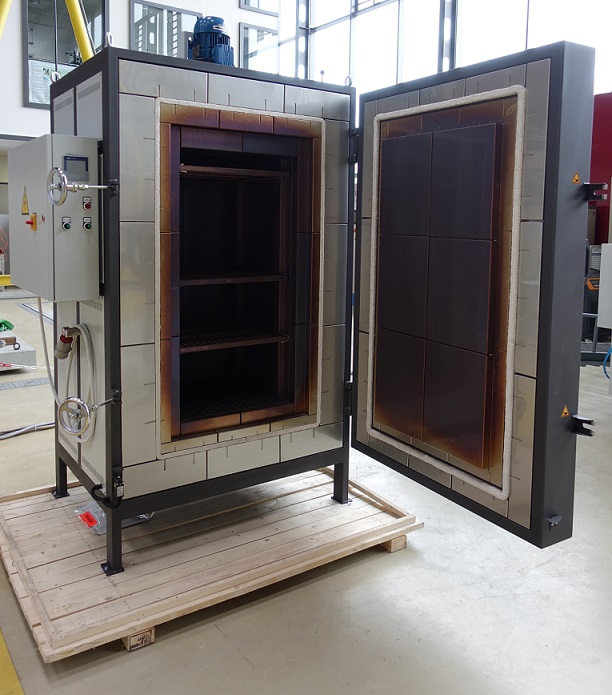

Air circulation and curing oven

ENA 430/500/18

- Temperature operating range: 20 °C - 500 °C

- Temperature stability (without input): ±1°C

- Temperature uniformity (without input): ±6°C

- Oven atmosphere: Air / circulating air

- Internal dimensions (W x D x H): 600 mm x 600 mm x 1200 mm

- Inner lining: Stainless steel

- Opening for vacuum hose 25 mm diameter: 2

- Power: 18 kW

- Voltage: 400 V

Chamber oven (2 pieces)

Nabertherm N 7/H

- Internal dimensions (WxHxD): 250 x 250 x 140 mm

- Volume: 9 litres

- Max. temperature: 1280 °C

- Minutes to Tmax: 180

- Heat output: 3.0 kW3

Planetary mill

Fritsch Pulverisette 5

- Grinding stations: 4

- Grinding tools: Grinding bowls and grinding balls

- Materials of the grinding tools: agate, corundum, sialon

- Grinding bowl size: 500 ml

- Max. feed size (depending on material): 10 mm

- min. Sample quantity: 10 ml

- Max. sample quantity: 900 ml

- Final fineness dry grinding: d50 < 20 µm

- Final fineness wet grinding: d50 < 1 µm

- Typical grinding time: 4 min

- Main disc speed: 50 - 400 rpm

Knife mill

Retsch Grindomix GM 200

- Capacity: 700 ml

- Speed: 2000 - 10000 rpm

- Speed steps: 500 rpm

- Drive: 750 W

- Feed grain size: < 40 mm

Professional laboratory mixer

Ceramic Instruments srl Planetaria LT/10

- both planetary and rotary rotation

- Capacity: 10 litres

- Rotation speeds: 108 rpm, 195 rpm, 355 rpm

Processing centre for additive and subtractive component manufacturing

CNCbárcenas Super Discovery 3D Printer Workstation

Printing:

- Print volume: 1,300 x 2500 x 1000 mm

- Nozzles: 2.5 mm, 4 mm, 5 mm, 10 mm, 15 mm, 20 mm

- Nozzle temperature: 450 °C

- Heating bed temperature: 175 °C

- Process speed: 200 mm/s

- Volume flow: 10 kg/h (with ABS-CF20)

- Material form: granulate/pellets

- Supported materials: ABS-CF, ABS-GF, PA6-CF, PP-CF, PPE, PC, PEI, PETG, PEEK, ULTEM, among others

Milling:

- Spindle power: 4.5 kW

- Speed range: 0 - 18,000 rpm

- Vmax (milling): 15 m/min

- Supported materials: CF fibre-reinforced thermoplastics, aluminium 6061 T6

FFF 3D printer

Smart3D MACRO Prototyping Unit - High Temperature

- Print volume: 350 x 350 x 400 mm

- Print head: Dual extrusion

- max. nozzle temperature: 500 °C

- max. chamber temperature: 200 °C

- Layer height: from 0.02 mm

- Accuracy: 0.05 mm

- Nozzles: 0.4 mm, interchangeable

- Extrusion flow: 47 mm3/s- 120 mm3/s

- Filament diameter: 1.75 mm

- Supported materials: PLA, ABS, PEEK, PEKK, PEI Ultem 1010, PEI Ultem 9085, PPSU, carbon fibre reinforced filaments, ...

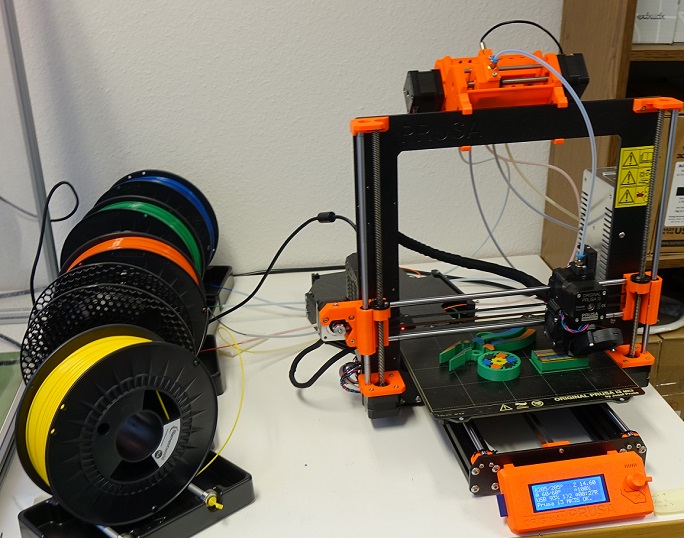

FFF 3D printer

Prusa i3 MK4

- Print volume: 250 x 210 x 220 mm

- Layer height: from 0.05 mm

- Nozzles: 0.25 mm; 0.4 mm; 0.6 mm; 0.8 mm

- Printing: 200+ mm/s

- Max. print bed temperature: 120 °C

- Filament diameter 1.75 mm

- Supported materials: PLA, ABS, PET, HIPS, Flex PP, Ninjaflex, Laywood, Laybrick, Nylon, Bamboofill, Bronzefill, ASA, T-Glase, carbon fibre reinforced filaments, polycarbonates...

- Optical filament flow sensor

FFF 3D printer

Prusa i3 MK3

- Print volume: 250 x 210 x 210 mm

- Layer height: from 0.05 mm

- Nozzles: 0.4 mm, 0.6 mm, 0.8 mm

- Printing: 200+ mm/s

- Max. print bed temperature: 120 °C

- Filament diameter 1.75 mm

- Supported materials: PLA, ABS, PET, HIPS, Flex PP, Ninjaflex, Laywood, Laybrick, Nylon, Bamboofill, Bronzefill, ASA, T-Glase, carbon fibre reinforced filaments, polycarbonates...

- Optical filament flow sensor

Prusa i3 MK3S with MMU2S

- Print with up to 5 different filaments simultaneously

- Printing in single mode like the MK3

- Additional mechanical filament sensor

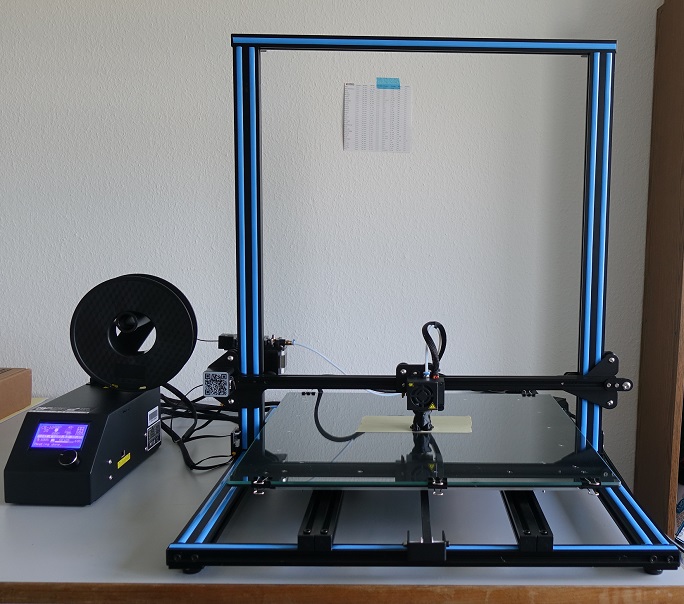

FFF 3D printer

Creality CR-10 S5

- Print volume: 500 x 500 x 500 mm

- Layer height: from 0.1 mm

- Accuracy: ± 0.1 mm

- Nozzles: 0.4 mm, interchangeable

- Printing: 30 - 60 mm/s, max. 180 mm/s

- max. nozzle temperature: 250°C

- max. print bed temperature: 60°C

- Filament diameter: 1.75 mm

- Supported materials: PLA, ABS, TPU, wood-reinforced filaments, carbon fibre-reinforced filaments

- Filament detector

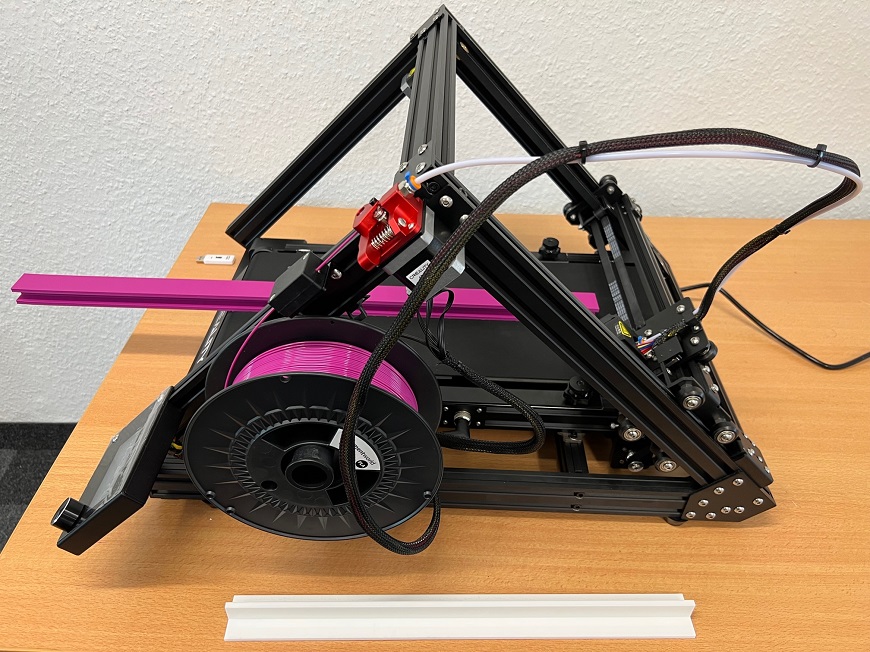

FFF 3D printer

Creality CR-30

- Print volume: 200 × 170 × ∞ mm

- Layer thickness: 0.1 mm - 0.4 mm

- Accuracy: ± 0.1 mm

- Nozzle: 0.4 mm, interchangeable

- Max. nozzle temperature: 240°C

- max. print bed temperature: 100°C

- Filament diameter: 1.75 mm

- Supported materials: PLA, TPU, PETG

- Filament detector

DLP 3D printer

Anycubic Photon M3 Plus

- Print size 245 x 197 x 122 cm

- LCD screen: 9.25-inch monochrome screen

- Resolution: 6K (5,760 x 3,600 pixels)

- Accuracy: 34µm

- Light source: Parallel matrix light source (40 LED beads) ≤ 44,395 lux light intensity

- Contrast ratio: up to 350:1

- Print speed ≤ 10cm/hour

- Smart Resin Filling

Anycubic Wash & Cure Plus

- Washing and curing

- Cleaning size: 192 mm x 120 mm x 235 mm

- UV light: 405 nm

- Curing size: 190 mm x 245 mm

- Time selection: 1-60min

- Rated power: 40W

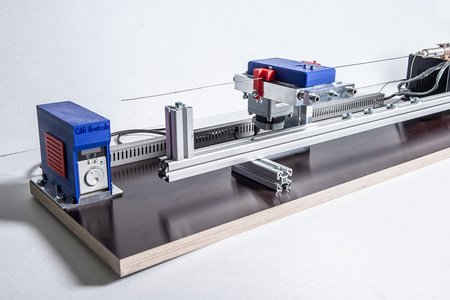

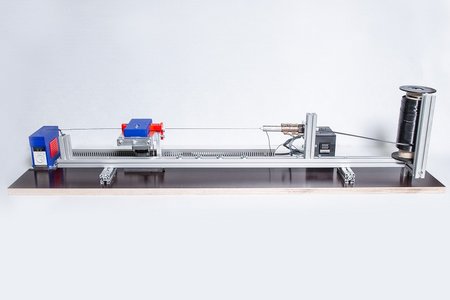

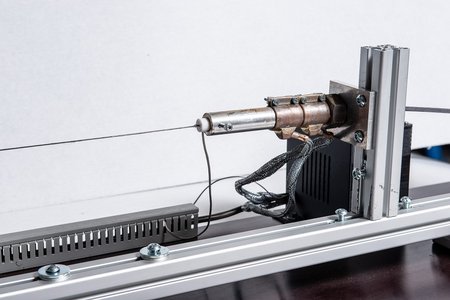

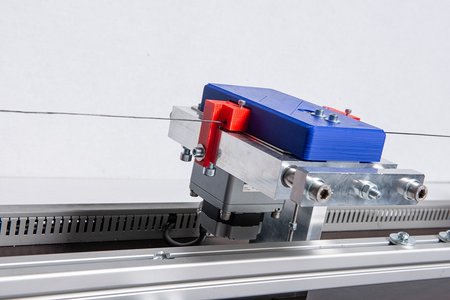

Pultrusion line

Extrusion system for the flexible production of continuous fibre-reinforced FDM/FFM filaments

- Materials: PP-CF, PA6-CF, PP-GF, PA6-GF, etc.

- Tape width: ¼" (number of tapes depending on the nozzle cross-section)

- Tmax preheating section: 400°C

- Pull-off speed: 0-300 mm/s

- Pull-off force: <100 N

- Nozzle cross-sections: 0.5-3 mm circular cross-section

- Air cooling

Hydrogen container test centre

MAXIMATOR - Burst and cycle test bench

- Burst test bench (max): 2500 bar

- Cycle test bench: variable (on request)

- Maximum tank size (max): 3 m

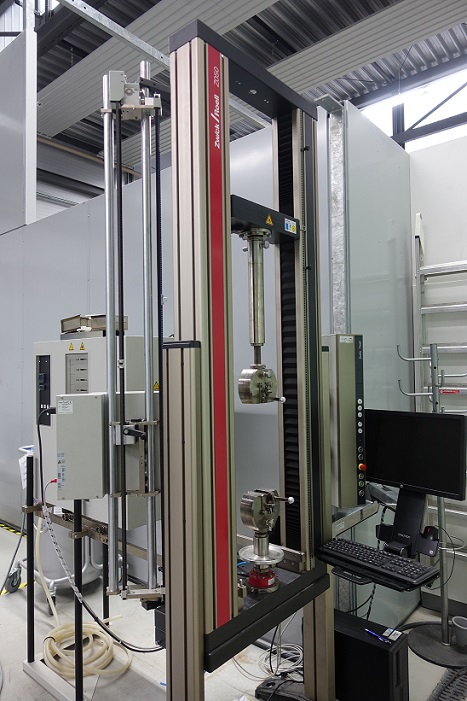

Tension/compression torsion machine 1MN

ZwickRoell Z1200E

- Universal testing machine

- Compression / tension: 600 kN (depending on fixture)

- Torsion: 4k Nm (also combined)

- Clamping tools for a variety of different tests

- Thermal chamber: -40°C to 250°C

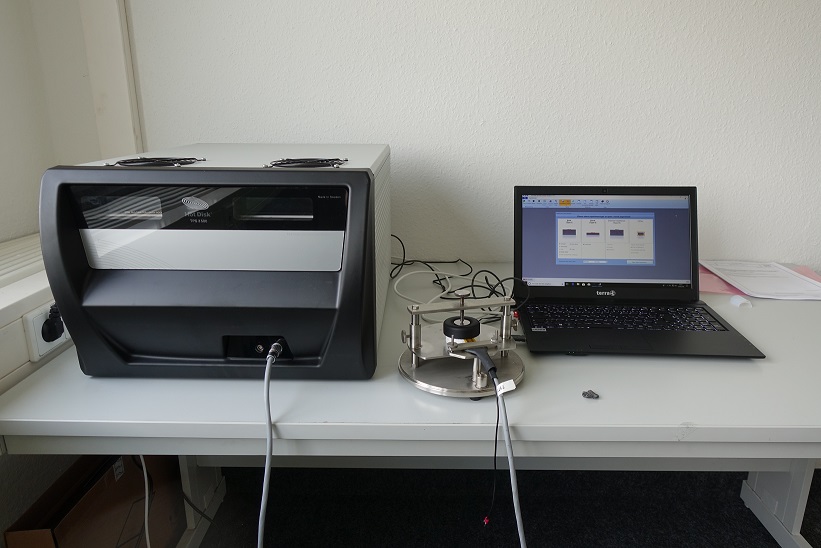

Thermal conductivity measuring system

Hot Disk TPS 3500

- Thermal conductivity: 0.005 - 1800 W/mK

- Thermal conductivity: 0.01 - 1200 mm2/s

- Specific heat capacity: up to 5 MJ/m3K

- Measuring time: 0.1 - 2560 s

- Sensor radius: 2.0 mm and 6.4 mm

- Specific heat capacity sensor with gold cell sample holder

- Isotropic and anisotropic determination

- Complies with ISO 22007-2

Digital microscope

Keyence VHX-7000

- Magnification: 10 - 5000x

- Extension to large stitching images

- Travelling table

- Surface 3D scan

- Sample preparation: possible (on request)

Mobile ultrasonic phased array testing device

OmniScan SX 16:64PR (mobile version)

- Phased array probe

- 5 Mhz line array

- 64 piezo elements on 32 x 10 mm

- Cable length 10 m

- Probes for conventional ultrasonic testing

- Angle probes ABSA-5T (-45°, -60°, -70°)

- Dual probe DL4R-3.5X10

- Flaw detection from 0 mm

- VERSAMOUSE displacement encoder

- 2D raster scan

- Magnetic wheel set

- Possible defect inspection:

- Production (pores, bonding defects, resin accumulations, etc.)

- Operational damage (e.g. crack propagation)

- Consequences of an impact (e.g. damage propagation (in x, y, z)

- Centre of gravity test

- CFK, GFK, AFK, NFK

- Hybrid laminates

- Joints (bondings, overlaps, shafts, etc.)

Universal tensile and compression testing machine

Zwick/Roell Z050

- Test load: max. 50 kN

- Test area height: 1380 mm

- Test area width: 440 mm

- Positioning repeatability on the crosshead: ± 2 μm

- Crosshead speed: 0.0005 mm/min - 600 mm/min

- Cycle time: 1000 Hz

- Travel resolution of the drive: 0.31789 nm

- Maximum torque: 200 Nm

- Angular speed up to 12 °/s

- Temperature chamber: -40°C to +250°C

- Closable openings for strain measurement

Universal tensile and compression testing machine

Zwick Z030

- Test load: max. 30 kN

- Test area height: 1380 mm

- Test area width: 440 mm

- Positioning repeatability on the crosshead: ± 2 μm

- Crosshead speed: 0.0005 mm/min - 1000 mm/min

- Cycle time: 1000 Hz

- Path resolution of the drive: 0.31789 nm

Contact angle measuring device

Dataphysics OCA 20

- 3 electronically controlled syringe modules for liquid dosing

- CCD (charge-coupled device) camera with a resolution of 768 x 576 pixels

- Data transfer rate video system: 132 Mbyte/s

- Digitising speed of video system: 50 measured values/s

- Electrical thermostatic device with TEC 350 temperature controller (up to 350 °C)

- Sample table: 100 x 100 mm

- Fast and precise manual positioning of the sample stage

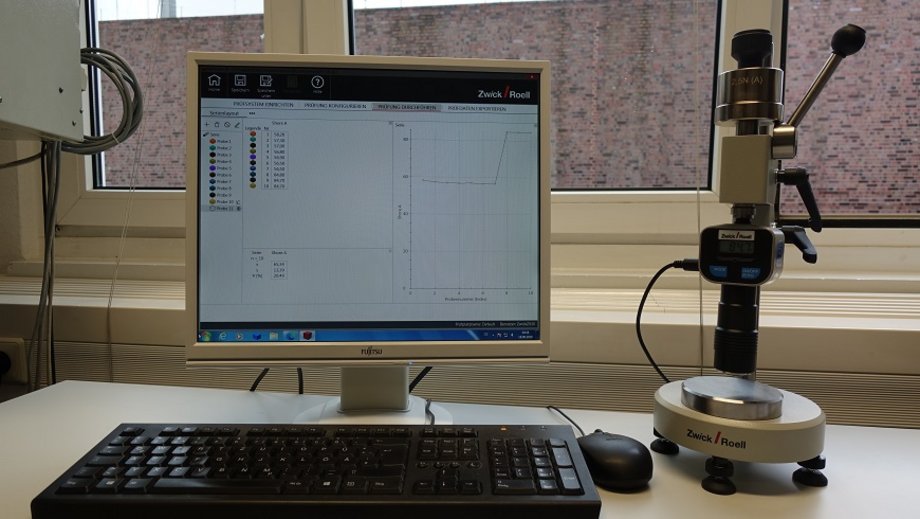

Shore hardness tester - digital

Zwick/Roell 3130 / 3131

- Hardness test according to Shore A, ISO 48-4, ASTM D 2240

- Area of application: Soft rubber, elastomers, natural rubber

- Hardness test according to Shore D, ISO 48-4, ASTM D 2240

- Area of application: Hard rubber, rigid thermoplastics

Permeability measuring cell In-house development

- Experimental determination of the planar permeability (K1, K2) of reinforcing textiles

- One-dimensional measuring method

- Max. Injection pressure: 5 bar

- Optical flow front detection

- In-situ temperature measurement

- Variable preform thickness (2-5 mm)

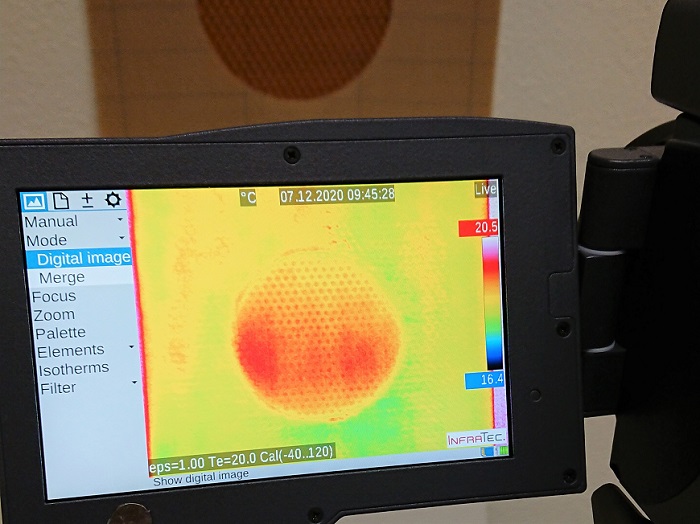

Thermography system

InfraTec VarioCAM HDx 645

- Mobile or stationary use

- Measuring range: -40 °C to 600 °C

- Resolution: 640 x 480 pixels

- Thermal resolution @ 30 °C: 0.03 K

- IR image frequency: 30 Hz (full screen)

- Integrated 8 megapixel digital camera

- Option: Active thermography

- Comprehensive software package (IRBIS 3.1)

Thermography system

InfraTec VarioCAM high resolution

- Mobile thermographic camera

- Measuring range: -40 - +2000°C

- Resolution: 640 x 480 pixels (resolution enhancement to 1280 x 980)

- Temperature resolution @ 30 °C: 0.08 K

- Measuring accuracy: ± 1.5 K

- IR image frequency: 50/60 Hz

Thermography system

FLIR T420

- Mobile infrared handheld camera system

- Measuring range: -20 °C to 1200 °C

- Resolution: 320 x 240 pixels

Integrated 3.1 megapixel digital camera

FLIR software package for processing and analysing the measurement data

Thermography system

FLIR C5

- Very compact thermal imaging camera

- Measuring range: -20 °C to 400 °C

- Resolution: 160 x 120 pixels

- Integrated 5 megapixel digital camera

- Dimensions: 138 x 84 x 24 mm³

- FLIR software package for processing and analysing the measurement data

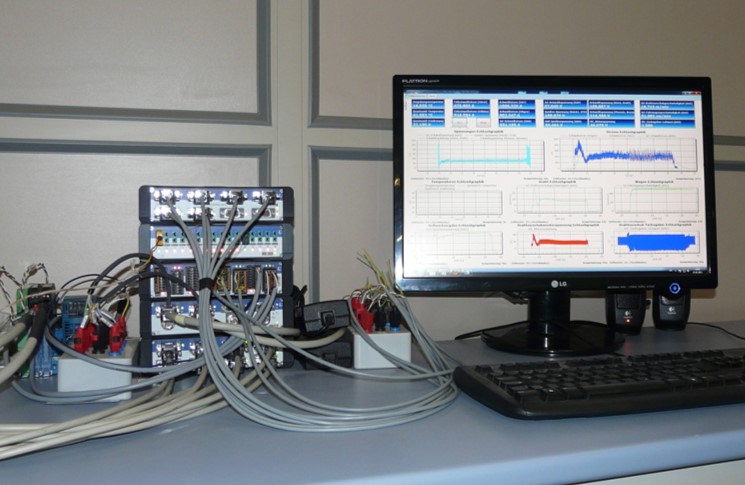

HBM Quantum X measuring systems

MX840B

- Universal measuring amplifier

- 8 individually configurable measuring channels

- Connection of more than 16 transducer technologies per channel

- Measurement rates up to 40 kS/s

- 24-bit A/D converter per channel

- Automatic channel parameterisation (TEDS)

- Supply voltage for active transducers (DC): 5 - 24 V

- CAN bus input or output (port 1)

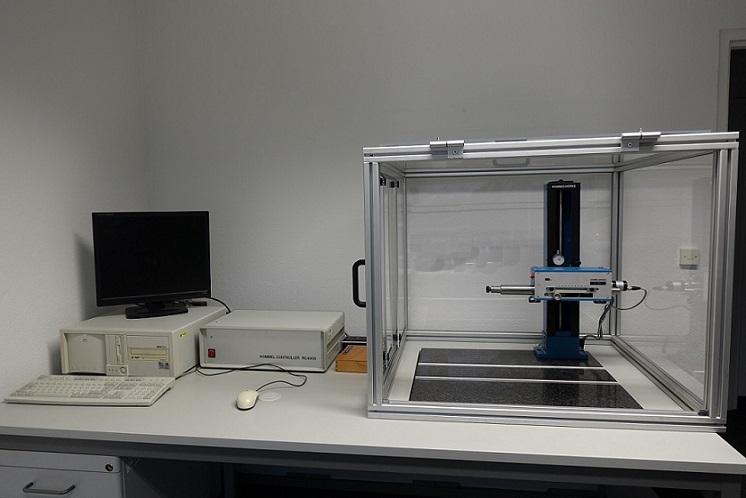

Roughness, profile and form measuring station

Hommelwerke RC 4000

- Profile measurement with Hommel probe PM 2000

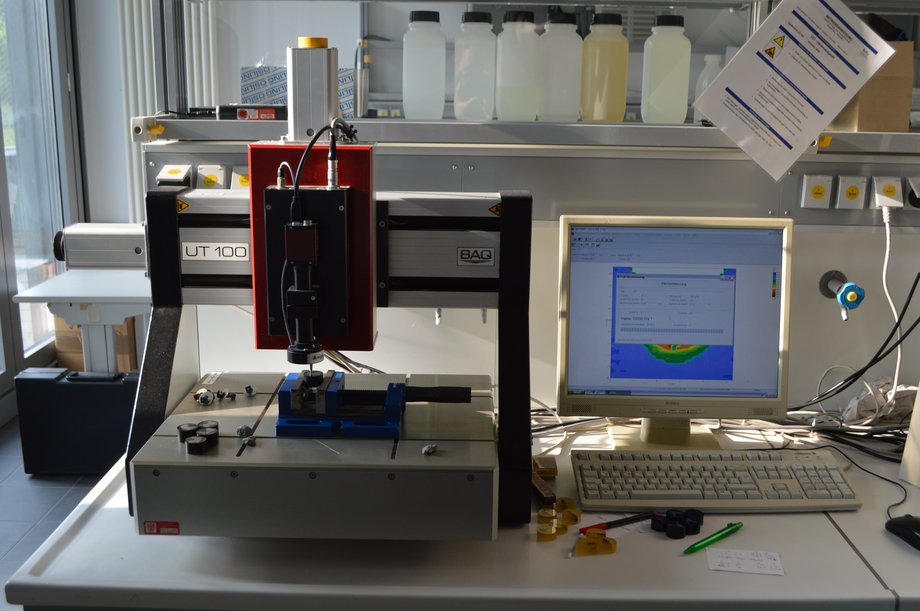

Area hardness measurement

BAQ UT100

Macro thermobalance

HTM Reetz GmbH LK 1100-100-300-1

- max. sample size: 50 x 50 x 50 mm

- max. sample weight: approx. 50 g

- max. temperature: 1100 °C

Light microscope

Carl Zeiss Axiotech 100HD-3D

- UK1275 CMOS digital camera for Comef43 digitisation and image analysis software

- 4 magnification optics (1.25x; 5x; 10x; 50x)

- Sample stage: 190 x 250 mm

Light microscope

Leica DM 2500 M

- Magnification: 5x, 10x, 20x

- FoV: 20 mm

- 2 incident light axes (4x and 5x axis)

- 3 objective nosepieces

- Sample sizes up to 100 x 100 mm

- Sample heights up to 80 mm

- All microscopic contrast methods available

Stereomicroscope

Leica M80

- Magnification: 7.5× - 60×

- Eight switchable, latching zoom levels

- Optics with excellent contrast for detailed visualisation of the sample

Rotational rheometer

RHEOMETER RHEOTEST RN with heating plate

for rotation tests (in shear rate or shear stress controlled mode / CR/CS) as well as shear stress or deformation controlled oscillation tests (OSC)

- Measuring principle according to DIN 53019

- Torque range: 0.1 - 150 mNM

- Torque resolution: 0.001 mNm

- Measuring angle range: 0 - 5 *106 µrad

- Measuring angle resolution: 11.87 µrad

- Speed range: 0 - 2000 rpm

- Speed resolution: 0.015 rpm

- Viscosity range: 1 - 1010 mPas

- Angular frequency range: 6.28 * 10-5 - 628 rad/s

- Frequency range: 0.001 - 100 Hz

- Normal force range: -30 - 30 N

- Normal force resolution: 0.01 N

- Temperature range electrical heating: +35 - +300 °C

- Temperature resolution: 0.01 °C

- Temperature accuracy: <= 0.5 K

- Heating speed: 60 K/min (temperature jumps)

- 30 K/min (linear temperature ramps)

- Rheotest RN 5.1

Rotational rheometer

RHEOTEST RN 4.1

- Measuring principle according to DIN 53019

- Torque range: 0.1 - 150 mNM

- Torque resolution: 0.002 mNm

- Speed range: 0 - 1000 rpm

- Speed resolution: 0.015 rpm

- Viscosity range: 1 - 3*109 mPas

- Phase angle range: 0 - 90

- Frequency range: 0.001 - 10 Hz

Viscometer

PCE-RVI 2 V1L (PCE Instruments UK ltd.)

- Measuring principle: Rotational viscometer ATSM/ DIN ISO 2555

- Rotational speed: 0.3 - 200 rpm

- Viscosity range: 3 - 2000000 mPas

- Accuracy: +/- 1%

- Temperature: -15 - +18 °C

- Resolution: 0.1 °C

Plasticity tester according to Pfefferkorn

Toni technique

- Determination of the plasticity index according to Pfefferkorn

Workplace for hand lamination

Vacuum infusion

Vacuum pump Edwards XDS 10

Rotary vane vacuum pump D.V.P: LC.4

- Minimum ultimate pressure: 2 mbar

- Maximum flow rate: 4.02m3/h

Vacuum pump Büchi V-600

- Minimum ultimate pressure: 1.5 mbar

- Maximum delivery rate: 3.1m3/h

- Three-stage vacuum pump with PTFE-coated diaphragm

- Remote operating interface I-300

Wet separator

ATIKA ST 300

- Diamond cutting disc

- water-cooled

- swivelling up to 45

- 1500 W / 3000 1/min

- Application for laminate and sample cutting

Freezer

Beko HSA 47520

- Useful capacity: 451 litres

- Freezing capacity (kg/24h): 20

- Ambient temperature: -15 - +43 °C

- Energy efficiency class: A+

Stud welder

AS ISO 66

- Material: (stainless) steel, aluminium, brass

- Welding range: ∅2 - 8 mm (isonails, disc pins, threaded studs, pins, internally threaded bushes)

- Welding time: 1 - 20 ms

- Welding sequence: 17 - 60 pcs/min

- Capacitor capacity: 66 mF

- Charging voltage: 60 - 220V DC, infinitely adjustable

Construction

- SolidWorks

- Rinoceros 7

- RhinoCAM

- PTC Creo

- Autodesk Inventor

Calculation and simulation

- Abaqus

- ANSA

- Ansys with additional module nCode Designlife

- LS-DYNA

- optiSLang

- HyperWorks

- MathCAD

- Mathematica

- Origin Pro

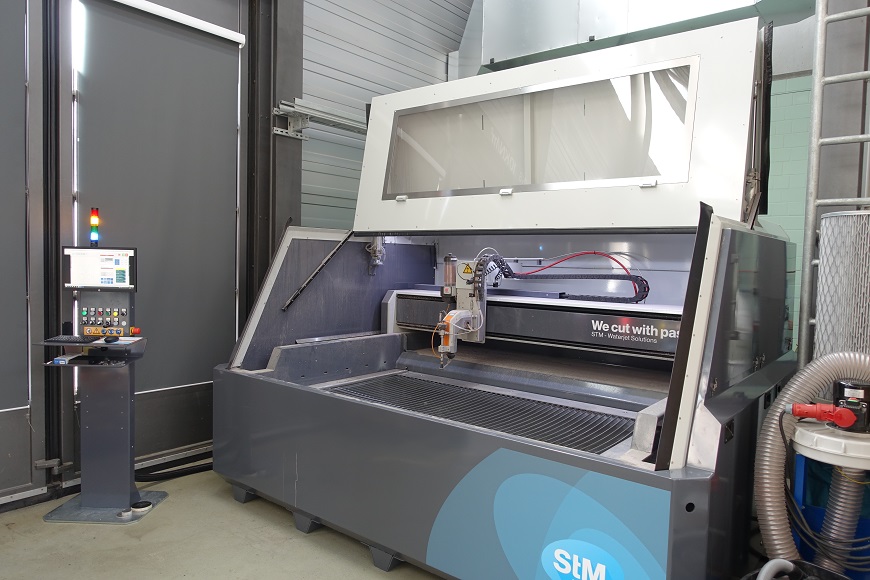

Water jet cutting system STM Waterjet GmbH Germany - STM 1020 Cube

For precise, CNC-controlled cutting of a wide range of materials using a pure water or abrasive water jet.

- Materials that can be cut: Steel, aluminium, plastics, wood, glass, etc.

- CNC working area: 1000 x 2000 x 100 mm

- Positioning accuracy: ± 0.08 mm

- Repeat accuracy: ± 0.05 mm

- Max. feed rate: ± 15 m/min

- infinitely variable pressure adjustment: 50 - 400 MPa

- max. continuous pressure operation: 380 MPa

- Delivery rate: 1.9 l/min

- abrasive quantity: 0 - 200 g/min

- Positioning laser

- Full enclosure

Compounding centre COLLIN Lab Line Compounder ZK25E-42D

Mixing and dispersing of pigments, mixing of fillers and other additives into polymers, mixing of fibre strands, mixing of polymers or pastes, degassing of volatile components, continuous reaction extrusion

- Co-rotating screws

- Screw diameter: 25 mm

- Length: 42 D

- Volumetric twin-screw feeder for granules and powders for main and side feeding

- SF 20 twin-screw side feeding system

- Lab Line strand granulator: Throughput approx. 20 kg/h

- Granulate length: 0.8 - 5.0 mm

- Granule size: 3 mm Ø x 3 mm

- Water bath: 2000 mm

FFF 3D printer Bambu Lab X1E incl. AMS

For the additive manufacturing of components, models and demonstrators using (fibre-reinforced) thermoplastics.

- Print volume: 256 x 256 x 256 mm

- Max. nozzle temperature: 320 °C

- max. chamber temperature: 60 °C

- Layer height: from 0.02 mm

- Accuracy: 0.05 mm

- Nozzles: 0.2 mm; 0.4 mm; 0.6 mm; 0.8 mm, interchangeable

- Extrusion flow: 32 mm3/s@ABS

- Filament diameter: 1.75 mm

- Supported materials: PLA, PETG, TPU, ABS, ASA, PC, PA, PPS, fibre-reinforced filaments, ...

- Air cleaning

- Automatic material system with up to 4 filaments

LSPc 3D printer Nexa 3D XiP Pro

For additive manufacturing of components, models, injection moulding tool inserts made of photopolymers (resins) with a high level of detail.

- Print size 292 x 163 x 410 mm

- LCD screen: 13.6-inch monochrome screen

- Resolution: 7K (6480 x 3600px)

- Vertical speed (with full build platform): 240 mm/h

- XY resolution: 46 µm

- Z resolution (layer thickness): 25 - 200 µm

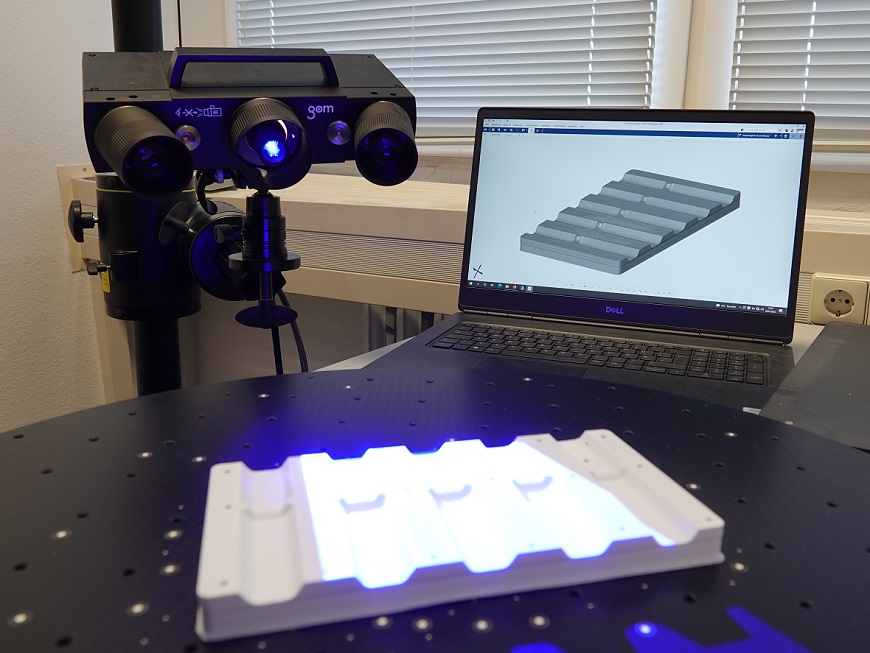

Optical 3D measuring system GOM ATOS Q 8M

For non-contact 3D measurement and inspection tasks to precisely capture and analyse the geometric shape of objects and components, e.g. for quality assurance.

- Measuring points per scan: 8 million

- Measuring range: 100 x 70 mm2, 500 x 370 mm2

- Point spacing: 0.04 mm, 0.15 mm

- Working distance: 490 mm

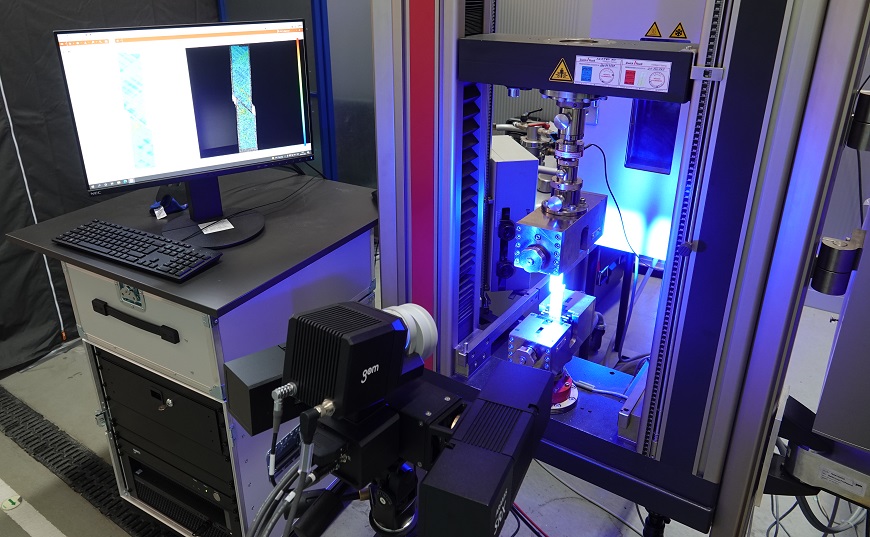

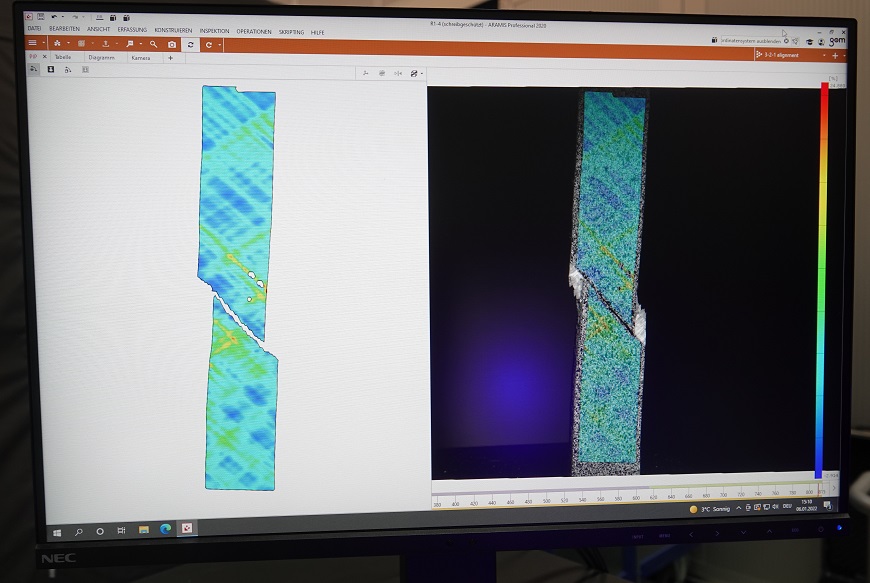

Surface deformation measuring system GOM ARAMIS SRX

For carrying out full-surface and point-based measurements for the precise recording of three-dimensional movements, deformations and strains of materials or complete components under load - for both static and dynamic tests.

- 2x 12 megapixel cameras

- Resolution: 4096 x 3068 pixels

- Frame rates:

- at 4096 x 3068 pixels: 75 fps

- at 4096 x 2000 pixels: 115 fps

- at 4096 x 1000 pixels: 230 fps

- at 4096 x 480 pixels: 480 fps

- at 1920 x 1100 pixels: 490 fps

- Measuring field: 165 x 1250 mm (MV170)

- Working distance: 700 mm