Overcoming borders with key technologies Development of a cross-border competence network for the Transfer of Knowledge and Technology in the field of application-oriented lightweight construction

Brief description

The aim of the bilateral project is to establish a competence network with stakeholders on both sides of the German-Polish border. In particular, the target groups of students, academic staff and employees are to be involved. As representatives of academic institutions and the regional economy, they are to accompany and organise the Transfer of Knowledge and Technology in the field of application-oriented lightweight construction from the universities to regional companies. The aim is not only to overcome geographical borders, but also to break down linguistic and mental barriers and thus ensure that contacts continue beyond the project. The accelerated and sustainable development of expertise in the field of the key technology of lightweight construction represents an opportunity for the upcoming structural change and the region.

Workshops

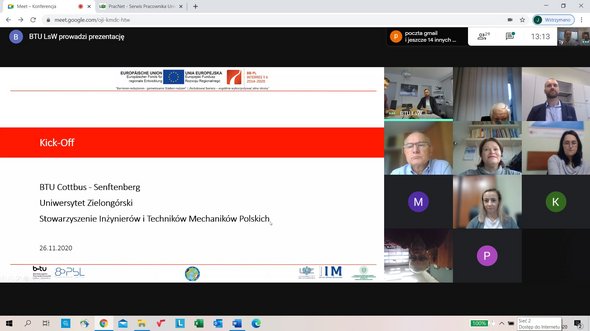

Kick-off event

On Thursday 26 November 2020, the BTU Cottbus-Senftenberg (BTU C-S), as lead partner, hosted the kick-off event for the INTERREG V A Brandenburg - Poland 2014-2020 project "Overcoming borders with key technologies - Sustainable development of a cross-border competence network for the Transfer of Knowledge and Technology in the field of application-oriented lightweight construction". The event was organised by the University of Zielona Góra (UZ), which is a project partner along with the Association of Polish Mechanical Engineers and Technicians (SIMP). Due to the coronavirus, however, the event could not be held on site as planned, but had to be moved to a virtual space. The online meeting was organised and moderated by Prof. Justyna Patalas-Maliszewska, Director of the Institute of Mechanical Engineering (IIM), and Prof. Sławomir Kłos - the Rector's Representative for Academic Entrepreneurship. The Gorzów branch of the Association of Polish Mechanical Engineers and Technicians involved in the project was represented by Mr Włodzimierz Fleischer. BTU C-S was represented by project manager Prof. Holger Seidlitz from the Chair of Polymer-based Lightweight Construction (PbL). During the conference, which lasted around two hours, the more than 30 participants were given details of the project and the project partners involved were introduced in more detail. The project details included both the INTERREG V A Brandenburg - Poland 2014-2020 funding programme of the European Union, with the help of which the project can be implemented, as well as the objectives and measures of the project. A translation from Polish into German and vice versa was ensured by the project partners. In conclusion, all project partners emphasised that they hoped it would soon be possible to meet again in person and thus maintain the intercultural exchange vis-à-vis.

With the help of the funds provided by the European Regional Development Fund (ERDF), the aim is not only to establish a bilateral competence network and thus strengthen the exchange between regional players from business and science, but also to increase cooperation between companies and universities in the field of research and development on both sides of the border in order to strengthen the region's innovation competence and thus provide impetus for the local economy and the labour market. The personal contact between the participants envisaged in the planned events, supplemented by the cultural and linguistic elements of the individual events, should help to reduce fear of contact across borders and break down language barriers. The group of participants should include students and academic staff as well as employees of local companies.

In order to realise the project, the grant agreement between the Investitionsbank des Landes Brandenburg (ILB) and BTU Cottbus-Senftenberg as well as the partnership agreements between the project partners involved were signed in September of this year.

Photos

Introduction to fibre composites

Contents

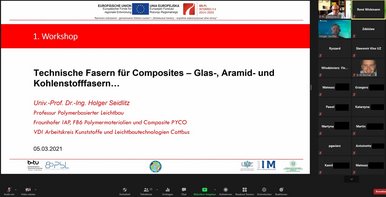

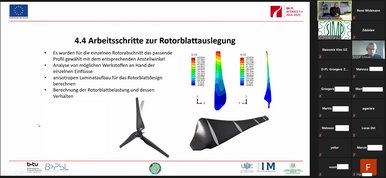

The bilateral project "Overcoming Borders through Key Technologies", which was approved as part of the INTERREG V A Brandenburg - Poland 2014-2020 programme, hosted its first workshop from 4 to 5 March. Due to the corona pandemic, however, the workshop could not take place on site at BTU Cottbus-Senftenberg as planned, but had to be moved to virtual space. Due to the resulting elimination of spatial restrictions, even more than the planned 30 people were able to take part in the varied programme. With the help of the Zoom video conferencing software, which enabled simultaneous interpreters to be easily integrated into the workshop, more than 50 participants attended the event.

Accompanying documents

Additive manufacturing with plastics and metals and the simulation of printed components

Contents

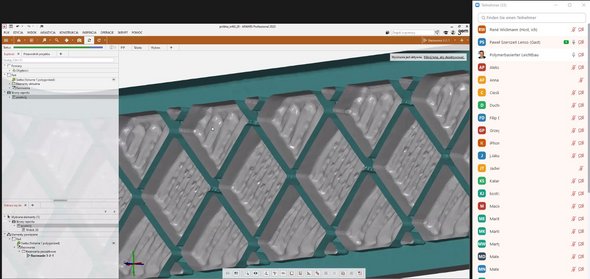

The second workshop of the German-Polish project took place from 21 to 22 April, this time hosted by the University of Zielona Góra. On Wednesday, Prof. Kłos welcomed the participants and familiarised them with autonomous systems for monitoring operating parameters. This was followed by the topic of 3D scanning for the first time for these two days. His practical presentation focussed on the recording of composite elements for the purpose of damage detection. If irreparable damage is detected, the components can often only be disposed of and this was the focus of the following topic, which dealt with the recycling of carbon fibres. The subsequent topics then centred on 3D printing. Before the lunch break, the focus was on 3D printing using metallic materials, while after lunch, additive manufacturing with plastics took centre stage. The Zielona Góra Philharmonic Orchestra provided the cultural contribution and thus the conclusion of the first day of the workshop, unfortunately only in the form of a video recording due to the pandemic. They played the symphony concerto "Peer Gynt" by Edvard Grieg.

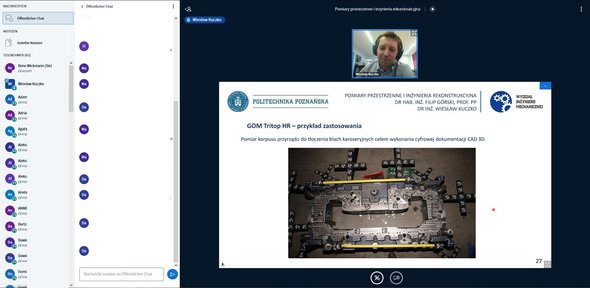

Prof. Patalas-Maliszewska began the second day with an introduction to the topic of Industry 4.0, in which she addressed the needs of manufacturing companies in the border region in particular. The next lecture continued across borders. Mgr inż. Zdzisław Wałęga presented various projects that students at the University of Zielona Góra have realised with the BTU Cottbus-Senftenberg, among others, and the advantages of lightweight construction. Apart from the actual topic, this is also an example of what good cooperation on both sides of the border can achieve. 3D scanning and reverse engineering took up most of the second day of the workshop. Prof. Filip Górski and Wiesław Kuczko used practical examples to show how objects that exist in the real world can be used to create digital models that can then be reproduced using additive manufacturing. This ranged from small items, such as dentures and prostheses, to the digitalisation of an entire substation.

Accompanying documents

- Flyer 2nd workshop (DE/PL)

- Lecture: A layer-by-layer introduction to additive manufacturing (DE/PL)

- Culture: The Zielona Góra Philharmonic Orchestra invites you to the symphony concert "Peer Gynt", Edvard Grieg. (Youtube Video)

Influence of anisotropic material characteristics on fibre composites and printed components

Contents

The third workshop of the German-Polish project took place from 26.05. - 27.05.2021, this time again hosted by BTU Cottbus - Senftenberg. After a short welcome and introduction, the workshop began with the basics of the production and properties of matrix polymers. A brief historical outline was followed by a breakdown of the manufacturing processes and the resulting categorisation into thermoplastics, elastomers and thermosets. The individual types of plastic and their properties were then discussed in more detail until lunchtime. The next topic, "Prepregs", was introduced after the lunch break with a practical example that presented the topic from the perspective of a manufacturer or user. This was followed by an academic approach to the module area. The first day of the workshop concluded with a cultural contribution. Mrs Stock from the Sorbian cultural information centre LODKA presented the history and development of the Sorbs, a minority group that was once widespread in the region.

The second day of the third workshop opened with the topics of bulk/dough/sheet moulding compounds and special compounds. As in the previous presentations, the focus was on how the properties of the materials can be specifically influenced by certain processing steps and thus optimally adapted to the component to be manufactured.

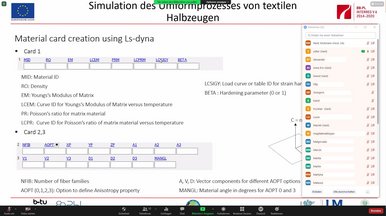

The following section dealt with component-specific design, focussing on the simulation of forming processes for semi-finished textile products. Here, the participants were not only explained the sequence of the individual steps leading to simulation, but this was also illustrated with a practical example. It was pointed out that simulation is an iterative process that may require several runs before the optimum solution is found. The same statement was also made in the practical example that followed the lunch break. Here, however, the participants were shown the entire process chain of component development using continuous fibre-reinforced plastics, of which simulation is a part. Here, too, the anisotropic properties of the materials were discussed and how this can result in advantages for the design. The workshop was rounded off with a language unit in which vocabulary from the first two events was repeated and terms from the current workshop were incorporated. Around 50 people took part in the video conference over the two days of the workshop.

Accompanying documents

- Flyer 3rd Workshop (DE)

- Flyer 3rd Workshop (PL)

- Simulation of the forming process of textile semi-finished products (EN)

- Culture: Sorbs (DE) (provided by the Sorbian Cultural Information Centre LODKA)

- Vocabulary (DE, PL, EN)

Construction methods with fibre composites and additively manufactured materials

Contents

The fourth workshop of the German-Polish project took place from 18 to 19 November under the leadership of BTU Cottbus - Senftenberg. The first of the two workshop days focussed on additive manufacturing and offered an overview of the current processes, both with plastics and with metal. Additive manufacturing using thermoplastics was then explored in greater depth with a practical example. Using a robot arm, plastic granulate is melted in an extruder and used to produce moulding tools. In this case, the thermoplastic material used is reinforced with glass fibres. The following article dealt with the possibility of making pressure vessels lighter and more resistant by using carbon fibres. Here too, the fibres and matrix are applied in layers until the desired component properties are achieved. After the lunch break, the next item on the agenda was photopolymerisation. In this process, resins cured under UV light are used to build up components layer by layer. A "spectacle lens" produced using this process was presented as a particularly impressive example. This was followed by the linguistic and cultural part of the workshop, which included learning new vocabulary for numbers and places and travelling to the Spreewald forest in a presentation.

The second day was dedicated to the major topic of construction methods with fibre composites. After the rather theoretical opening lecture on the difference between structural and lightweight material construction, Mr Müller took the participants on a journey from the historical beginnings of rail transport to current high-speed trains and how much this progress was also accompanied and made possible by the development of new materials (e.g. fibre composites). There was so much to report that the programme was extended beyond the lunch break. In consultation, the subsequent topic of structural optimisation was adapted and will be continued in one of the following workshops.

Accompanying documents

- Flyer 4th Workshop (DE)

- Flyer 4th Workshop (PL)

- Vocabulary (DE, PL, EN)

- Vocabulary - Exercise (DE, PL)

- Vocabulary - Solution (DE, PL)

Material mechanical characterisation

Contents

The INTERREG project "Overcoming Borders with Key Technologies" concluded the year with the fifth workshop from 9-10 December. 2021 was again marked by the pandemic, which virtually ruled out face-to-face meetings, which is why the fifth workshop was also held as an online-only event. However, as with the previous workshops, this format enabled a wider audience to participate in the event. Over the two days, more than 70 people accepted the invitation of this year's organiser, the Polish SIMP (Stowarzyszenie Inżynierów i Techników Mechaników Polskich), an organisation comparable to the Association of German Engineers (VDI) in Germany. After a welcome from the head of the branch in Gorzów Wielkopolski, Mr Fleischer, the introduction to the topic of "material mechanical characterisation" began with the characterisation of the mechanical properties of plastic composites and their failure mechanisms. The participants were then given an insight into research into high-pressure tanks made of composite materials, which are used for hydrogen storage, among other things, as well as the results of mechanical tests on fibre composites. The morning session was rounded off with an overview of test methods for determining the shear properties of fibre-reinforced plastics. The lunch break was immediately followed by the linguistic and cultural part of the workshop, in which the participants were first given an insight into the historical development of interaction between Poles and Germans. Historical documents, such as dictionaries, were used to trace and illustrate the development of mutual communication. The Polish Cluster for Composite Technology (Polski Klaster Technologii Kompozytowych) then introduced itself to the participants.

Friday, the second day of the workshop, began with a presentation of the technology laboratories of the Faculty of Technology at the Jakob von Paradise Academy and the opportunities they offer. The participants were then introduced to the testing of composite materials using eddy current testing, before the Centralne Laboratorium Urzędu Dozoru Technicznego, an institution comparable to the German TÜV (Technical Inspection Authority), discussed composite materials as functional materials in modern technology. The following presentations gave an insight into the practical application of fibre composites by means of two project examples. Before the lunch break, the focus was once again on fibre composite testing with a look at different types of fibres. After the lunch break, the programme continued with a practical presentation on the material testing of laminates from worn wind turbine blades and a recycling concept for the construction of a pedestrian bridge based on this. Given the large number of wind turbines that will soon reach the end of their service life, this is not an insignificant topic. The second day also ended with a cultural contribution before the farewell. Against the backdrop of the coronavirus pandemic and with the help of the much-discussed digitalisation, the SIMP took the participants on a virtual tour of the castle in Rydzyna. In addition to interesting facts about the history of the castle and how the SIMP came to own it, there was also information about its current use, such as the possibility of organising celebrations.

Accompanying documents

Photos

Structural analysis of anisotropic composites and design of layered composites and additively manufactured components

Contents

The seventh workshop of the German-Polish project took place from 07.04. - 08.04.2022, this time again hosted by BTU Cottbus - Senftenberg. After a welcome and a brief introduction to the two days of the workshop, the event began with the topic of lightweight design guidelines. The participants were given an overview of the structure of anisotropic composites and the design of layered composites, from the general design strategy to the execution of local structural stiffeners, the design of edge areas and the load-appropriate application of forces. After a break, the topic was deepened specifically for fibre-plastic composites, including an excursion into classical laminate theory and failure assessment. Python programs were also presented, which are used for calculation and visualisation and are made available to participants via the links below. After the lunch break to digest the theoretical knowledge, the participants were given practical examples to illustrate what they had previously seen. The day was rounded off with a linguistic and cultural block in which vocabulary relating to greetings, numbers and nationality was repeated and expanded.

Friday started with an introduction to the finite element method before moving on to the mainly practical part of the second day of the workshop. In a live demonstration, the participants were shown how to design, calculate and optimise a useful structure with the help of simulation programs using a practical example - the implementation of a robot arm. The day concluded with another linguistic and cultural unit before looking ahead to the next workshop.

A total of around 30 people took part in the seventh workshop over the two days.

Photos

Connection techniques and force application systems

Contents

The eighth workshop of the German-Polish project took place from 8 to 9 June, once again hosted by the University of Zielona Góra and offering a wide range of topics to those interested. After the opening and the introduction to the two days ahead, the first lecture, which focussed on advanced design methods, provided a link to the last event. This was followed by an insight into thermogravimetric research and its application in engineering. The underlying topic of robotic arms was taken up after the coffee break, in which a concept of a system for determining environmental conditions for controlling a mobile unmanned platform that works together with a robotic arm was presented. Before the lunch break, the participants learnt about the structure and mechanical properties of foundry silicas. The presentations in the afternoon focussed on the processing of steels, giving the participants the opportunity to look beyond plastics and towards metallic materials. The first day of the workshop concluded with a linguistic and cultural block, which gave the participants more information about Zielona Góra and the surrounding area in particular.

The following Thursday was mainly dedicated to test methods for analysing lightweight structures. However, methods for polymer and composite characterisation were the starting point before moving on to various inspection methods. The fourth lecture took a closer look at the effects of production-related defects in fibre-plastic composites using the example of shell structures in sandwich construction, before the next speakers turned their attention to verification and validation methods for composite materials. After the lunch break, the programme continued with optical methods for investigating plastics, before high-frequency electromagnetic methods concluded the second day of the workshop. This was followed by the summary and the outlook.

Accompanying documents

- Flyer 8th Workshop (DE)

- Flyer 8th Workshop (PL)

Photos

Manufacturing technologies for thermoplastic and thermoset composites

Contents

The ninth workshop in the series took place on 13 October 2022 on site at BTU Cottbus - Senftenberg and on 4 November 2022 in the usual setting. After around one and a half years of workshops in online format, the participants were now able to meet face to face for the first time and engage in dialogue. After a welcome from Prof. Seidlitz and a briefing on the organisational process, the participants were divided into groups to take a closer look at the manufacturing technologies for thermoplastic and thermoset composites available at the chair. The first group began with a visit to the Automated Fibre Placement (AFP) annex, which can deposit both thermoplastic and thermoset tapes and additively manufacture almost any geometry. With the large-scale 3D printer located in the same hall, the participants learnt about another additive manufacturing option. In contrast to the familiar desktop 3D printers, plastic granulate is moulded layer by layer into the desired shape of the component, including the shape of a pressure vessel, which will be revisited at a later date. At the next station, the group learnt where the granulate for the 3D printer comes from. In addition to the injection moulding machine and the flat film line, the compounder could also be seen in action, producing a new granulate from several components. At the hot press, the participants were able to see how a "2D" tape composite deposited with the help of the AFP was moulded into a 3D bicycle saddle. We moved on to the third station, where the winding system was explained to each group. As the name suggests, this is used to wrap liners with carbon fibres in order to produce lighter pressure vessels, for example. At this point, we came full circle to the first station, where the printed liners were presented, which are currently being used for experimental testing. After going through the three stations, there was a get-together of all participants before they went to lunch together. After refreshments, the cultural part of the workshop began. After brief excursions to Prince Pückler in previous workshops, the participants were now able to gain their own impression of the Prince's work. The Prince Pückler Museum Park and Branitz Palace Foundation gave the group a bilingual guided tour of both the palace and Branitz Park, providing interesting insights into the period. The tour and the workshop day ended with a look at and information about the pyramid in the park, the final resting place of Hermann von Pückler-Muskau.

The second day of the event served on the one hand to deepen the technologies presented on the first workshop day, but on the other hand also offered an introduction for those who could not participate on site in Cottbus to familiarise themselves with the various manufacturing technologies. After the welcome and organisational information, Prof. Seidlitz gave an overview of various basic processes, focusing in particular on injection moulding and extrusion. After a coffee break, the presentation continued with the hand lay-up process, prepregs and autoclave technology, as well as liquid composite moulding (LCM) and the pressing of components. The first item on the agenda after the lunch break followed on from the morning's topic of injection moulding and expanded on this in detail with the area of multi-component injection moulding. The production technologies of winding and braiding as well as automated lay-up processes in the form of Automated Tape Laying (ATL) and Automated Fibre Placement (AFP) concluded the workshop day. A total of 55 people took part in the online event, meaning that a larger group of people could be reached via this format than would have been possible through the face-to-face event alone.

Accompanying documents

- Flyer 9th Workshop (DE)

- Flyer 9th Workshop (PL)

Photos

Mould making for high-performance composites

Contents

The anniversary workshop of the German-Polish project took place from 16 to 17 November 2022. In order to enable the widest possible audience to participate, the 10th workshop was also held as a hybrid event. The BTU Cottbus - Senftenberg was once again the host for the topic "Toolmaking for high-performance composites". As always, 16 November 2022 began with a welcome and briefing on the course of the next two days before the topic of concepts and strategies for moulding tools was discussed. The concepts were first discussed against the background of the production technologies used, such as the press, the autoclave or automated fibre placement, before a second unit dealt with the materials to be processed and the specification of release agents, a basis for ensuring that the tool mould and component can be separated again after production. The topic was continued after the lunch break in the form of the design of demoulding chamfers and ejectors. This was followed by a practical session in which the participants were able to create their own moulds in CAD software under supervision. The first day of the workshop was rounded off with another linguistic unit designed to consolidate what had been learned so far in the form of dialogues.

On the second day of the 10th workshop, the participants met in presence this time in the teaching building 3A in Cottbus and received a briefing on the day's programme and the division into groups, in which they then went to various stations within the campus. By lunchtime, the participants were able to gain an impression of the manufacturing technologies presented the day before on site at the machines and how they are used to manufacture components. After lunch together, they walked from the university to the Cottbus town hall. The city guide was already waiting for the participants there. Starting from the town hall, the tour then took around an hour and a half through Cottbus' historic city centre. The route led past the Japanese tea house, Klosterplatz, Altmarkt, Tuchmacherbrunnen, Amtsteich and Goethepark, as well as the banks of the Spree. The stops on the tour were presented by the city guide in both German and Polish and the participants were able to ask her questions about them and the history of Cottbus. Afterwards, the group returned to the university and said goodbye to the guests.

Accompanying documents

Realisation of the subcomponents for the lightweight robot arm

Contents

The eleventh workshop took place from 23 to 24 November 2022 at two locations and this time entirely in person. The first day was organised by the University of Zielona Góra. After a welcome and a briefing on the organisational process, the participants were given an overview of the university's manufacturing technologies and laboratories. From 3D-SLM printers and optical measuring devices to a laboratory for aerospace equipment, the tour offered exciting insights that went beyond the necessary requirements for manufacturing a robotic arm. After the lunch break, the participants were given a cultural tour of Zielona Góra. One of the highlights was a visit to the Palm House, from where there was a wonderful view over the city. Another was the question of how many of the more than 60 Bacchus figures could be discovered on the tour.

On the second day, the BTU Cottbus - Senftenberg invited us back to its premises. The focus was on continuing the implementation of the fibre composite component started in the previous workshop. After repeating the LSAM process with subsequent milling at the combination centre for additive and subtractive manufacturing, the final manual preparation of the mould for the vacuum process was carried out. The mould was sanded smooth using fine sandpaper. At lunchtime, the cultural part of the day was followed by a visit to the Cottbus Christmas market, so that work could continue in the afternoon. Now that only the mould had been made, it was time to produce the actual component. Carbon fibre fabric was cut to size and draped in the mould. This was followed by vacuum drawing and soaking the fabric with resin. This marked the end of the second day of the workshop and the participants travelled back. Once the reaction time was complete, the component could be demoulded and then trimmed and will be presented at the next event.

Accompanying documents

- Flyer 11th Workshop (DE)

- Flyer 11th Workshop (PL)

Photos

Final workshop with test, trial and symposium

Contents

The twelfth and final workshop of the German-Polish project "Overcoming borders with key technologies - Sustainable development of a cross-border competence network for the Transfer of Knowledge and Technology in the field of application-oriented lightweight construction" took place from 7 to 8 December 2022. The project, which was realised as part of the Interreg V A Brandenburg - Poland 2014 - 2020 programme, brought together around 300 people from the German-Polish border region over a period of two years to discuss various topics. The initiators of the project were the Chair of Polymer-based Lightweight Construction (PbL) at the Brandenburg University of Technology Cottbus - Senftenberg (BTU C-S), the Institute of Mechanical Engineering (IIM) at the University of Zielona Góra (UZ), and the Gorzów Wielkopolski branch of the Association of Polish Mechanical Engineers and Technicians (SIMP - Stowarzyszenie Inżynierów i Techników Mechaników Polskich), which started developing the project with initial ideas back in 2018 and submitted the application in summer 2019. However, almost a year was to pass before the grant agreement was signed on 18 September 2020, during which the COVID-19 pandemic also took its course and led to the first border closures since reunification. In light of the quarantine regulations now in force and the changing labelling of risk areas, the project also had to be rethought and adapted to the circumstances. Nevertheless, the kick-off meeting was held on 26 November of the same year and the project was presented to an interested audience. Like the following events, this meeting was organised as an online event. The first workshop in the series was held purely digitally in March 2021. Even here, both advantages and disadvantages of the online format became apparent. While interaction was limited to technical matters, the online platform offered more people the opportunity to take part in the individual events than would have been possible in person due to space constraints. With an average of roughly 50 participants per workshop, the number of people was increased by around 2/3 from the target of 30. The next seven workshops were also held online and were organised alternately by the project partners. With the ninth and tenth workshops, there was a further change in the method of implementation and thus a move towards the originally planned concept, as both workshops were held in hybrid form. On one day, the online format was retained, thus relying on the tried and tested format, and on the second day, the format was changed to face-to-face, so that the participants had the opportunity to meet in person and actually experience practical elements on the machine. The eleventh workshop then returned to its roots and took place purely in person, both on this side and on the other side of the border. With the symposium as part of the 12th workshop and just under 50 participants, the series now came to a crowning conclusion, with an overview of the topics covered once again through presentations and a small exhibition. Looking back over the last two years, the workshops have reached a larger group of people than originally assumed, with around 300 participants, and with a proportion of women of around 26.5 %, they have exceeded the national average in Mechanical Engineering. Apart from these successes, which were not to be expected due to the bad omens, the first ideas for new projects to further strengthen co-operation on both sides of the border were already developed during the workshops. It was also possible to establish contacts between the research institutions and local companies in order to expand co-operation at this level too. Finally, the organisers would like to thank all the officers, interpreters, participants, the Joint Secretariat, the Marshal's Office of the Lubuskie Voivodeship and the Brandenburg Investment Bank (ILB) for their cooperation and contribution to the success of this cross-border and cross-border project!

Accompanying documents

- Flyer 12th Workshop (DE)

- Flyer 12th Workshop (PL)