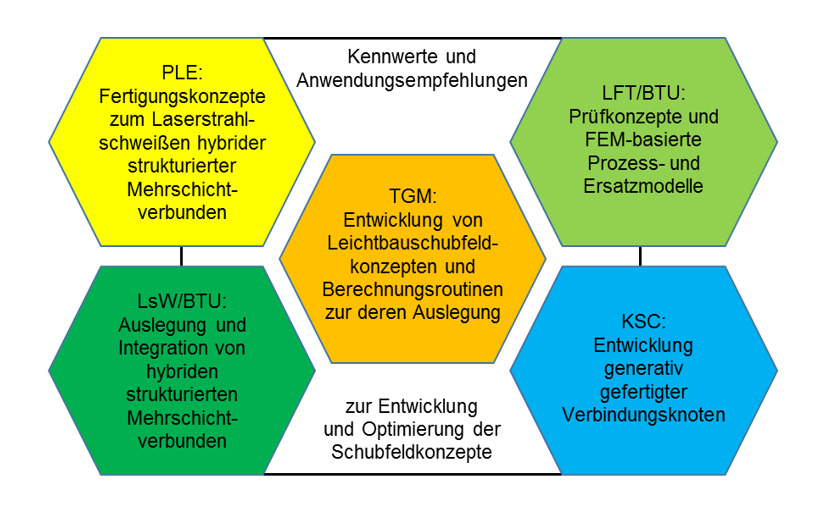

BTU/LsW

The Department of Lightweight Design with Structured Materials at BTU Cottbus - Senftenberg is responsible for the following core tasks within the joint project:

- Construction, design and processing of hybrid multilayer composites

- Development of structured moulds for the production of shear panel shells

- Development of FE replacement models for FRP/metal mixed joints

- Investigations into the damage-tolerant cutting of hybrid multi-layer composites

- Creation of recycling strategies

BTU/LFT

The Chair of Joining and Welding Technology at BTU Cottbus - Senftenberg is responsible for the following core tasks within the joint project:

- Development of simulation models for additive manufacturing as well as replacement models for joined and additively manufactured nodes

- Development of test concepts for generatively manufactured as well as all other demonstrator stages, i.e. test specimens with an increasing degree of complexity

- Testing of components under static, oscillating and dynamic, crash-like loads as well as climatic or corrosive stress conditions

- Development of suitable mechanical joining concepts for additively manufactured components

PLE

Photon Laser Engineering GmbH is responsible for the following core tasks within the joint project:

- Further development of laser beam joining of frame-planking connections in lightweight constructions and mixed construction concepts

- Development of a design and manufacturing concept for the large-scale production of modularised lightweight e-containers

- Development and adaptation of the manufacturing and quality assurance concepts

- Creation of an overall demonstrator

TGM

TGM Lightweight Solutions GmbH is responsible for the following core tasks within the joint project:

- Structural-mechanical analysis and weight optimisation of the modular mechanical shear panel support system for lightweight equipment containers

- Development of the design concept for the overall system

- Development of the manufacturing concept for the push field application

- Creation of a software tool for efficient weight-saving potential assessment

KSC

Kraftwerks-Service Cottbus Anlagenbau GmbH is responsible for the following core tasks within the joint project:

- Development of generatively manufactured connection nodes for integration into shear field systems

- Development of lightweight adhesive joints for the support structure/node interface Economic analysis of the node variants

- Validation of the metallic and plastic-based node solutions on the technology demonstrator