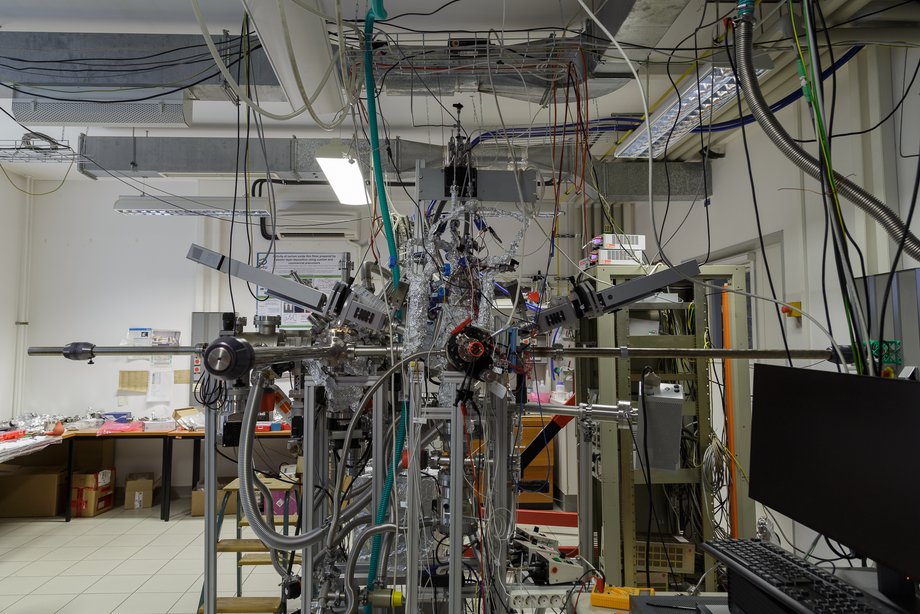

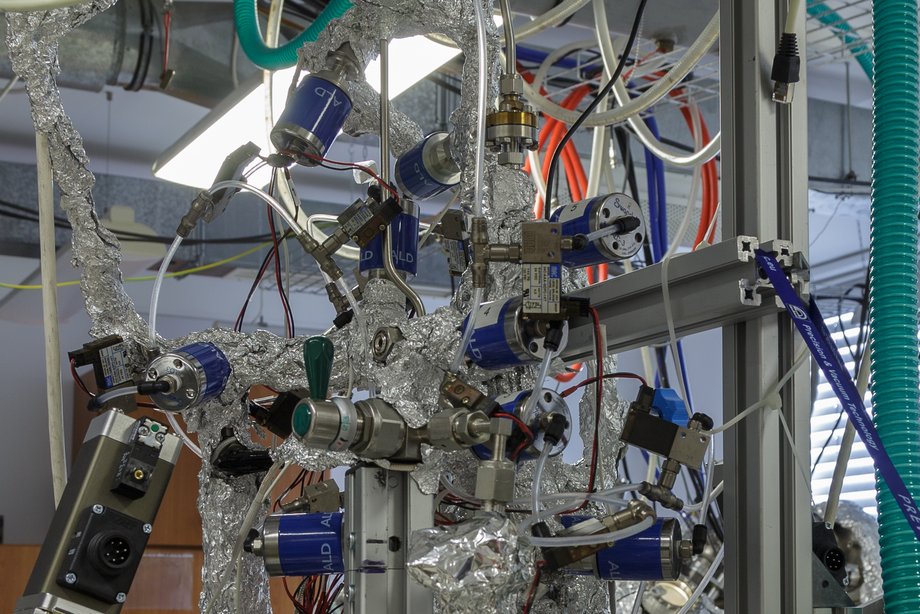

in-situ ALD cluster

System for atomic layer deposition (ALD) with integrated

- in-situ photoelectron spectroscopy (XPS)

- operando spectroscopic ellipsomtry (SI)

- operando quadrupol mass spectrometry (QMS)

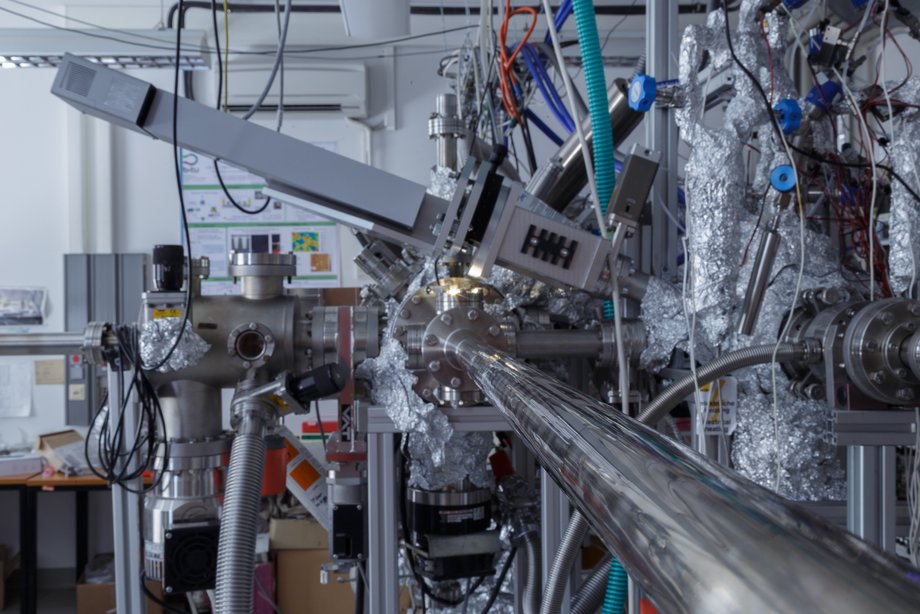

ALD Reactor

- UHV compatible stainless steel chamber

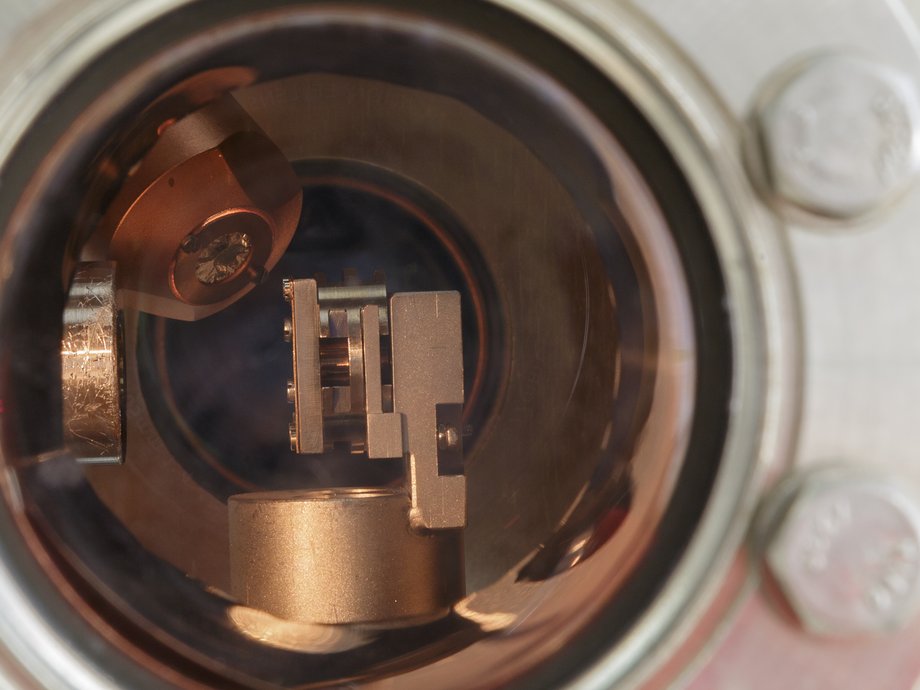

- Heatable sample holder (up to 1000°C) with SiN heater

- 3 axis linear manipulator with θ rotation

- Pump- or flow-type mode of ALD

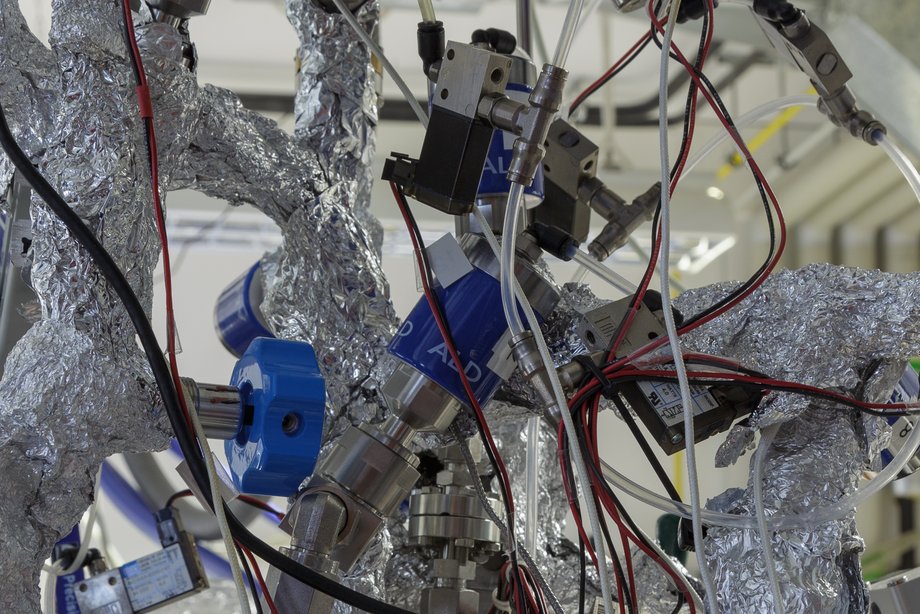

- Gas mixing and supply:

- VCR-based

- 3 main lines contrpolled via mass flow controllers (Bronkhorst)

- 3 precursor lines (for high, medium, and low vapor pressure)

- 3 oxidant/reactant lines (H2O, O3/O2...)

- 1 purge line (N2)

- Lines heatable up to 120°C

- Pneumatic ALD valves

- Ozon generator (Oxidation Technologies)

- Control software: Lab-View

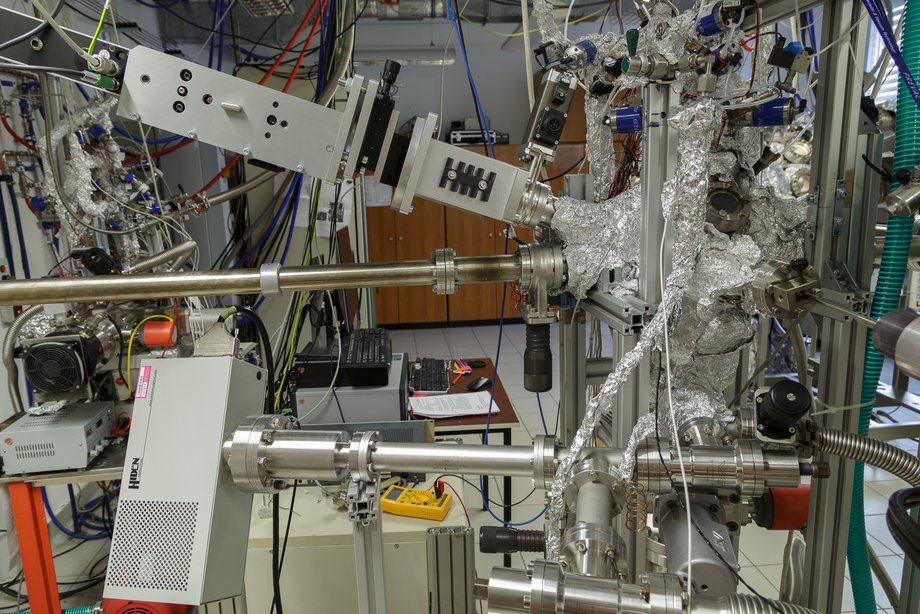

XPS (in-situ)

- Load-lock chamber with sample storage

- Preparation chamber (thermal or gas traetment before and after the ALD growth)

- Gas analysis via mass spectrometry (MKS)

- Additional deposition by thermal or e-beam evaporation

- Analysis chamber

- Al/Mg twin anode (non-chromatized)

- Hemispherical electron analyzer: Omicron EA125

- Detector: 5 channeltron

SI (operando)

- Spectroscopic ellipsometer SER 801 (SENTECH Instruments GmbH)

- 240 nm to 1000 nm (UV-VIS)

- Installed at 70° to the sample surface normal

- Protection of viewports by pneumatic valves to avoid undesired depositions

- Software: SpectraRay/4

QMS (operando)

- Quadrupol mass spectrometer HAL/3F 301 RC (Hiden Analytical)

- Adaption at ALD reactor via blind flange with an aperture (⌀=500mm) and differential pump station