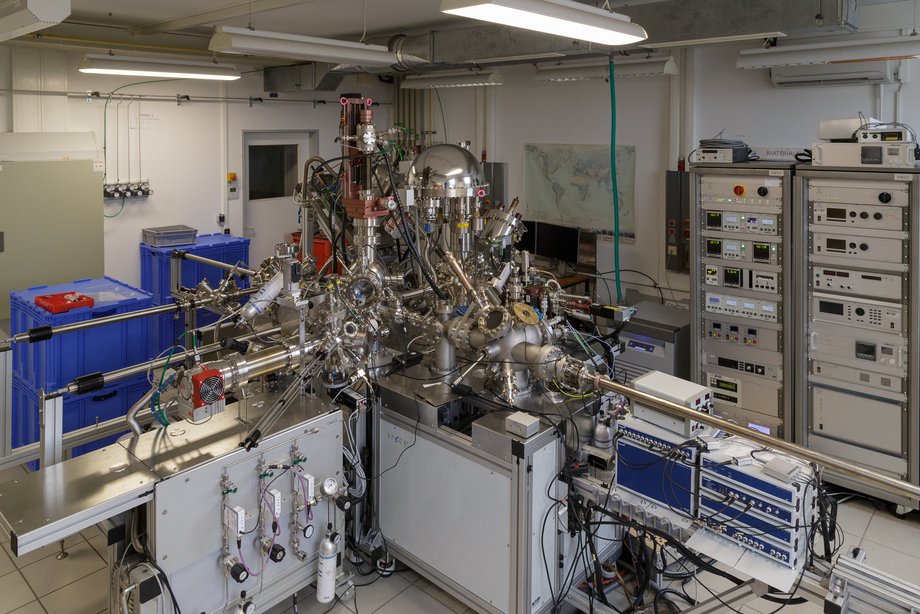

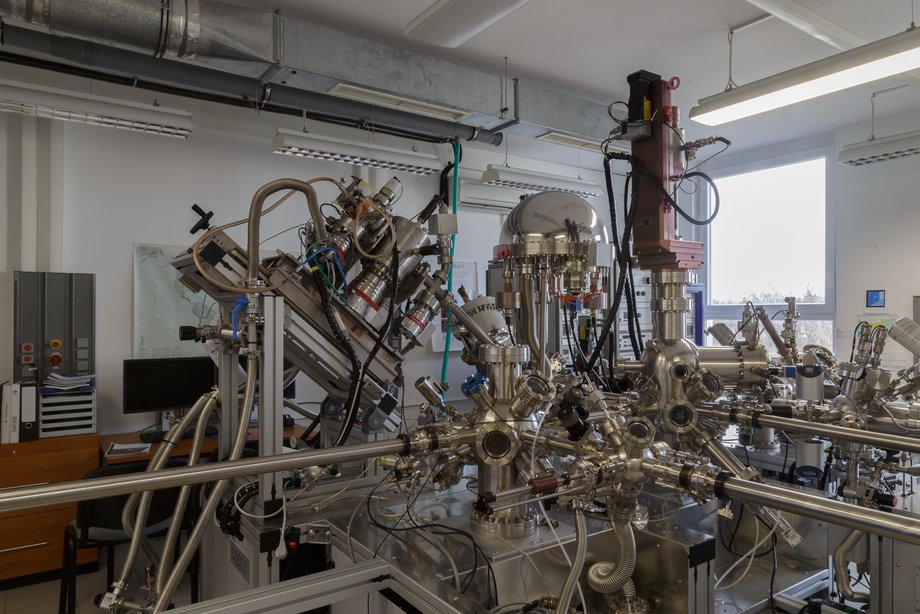

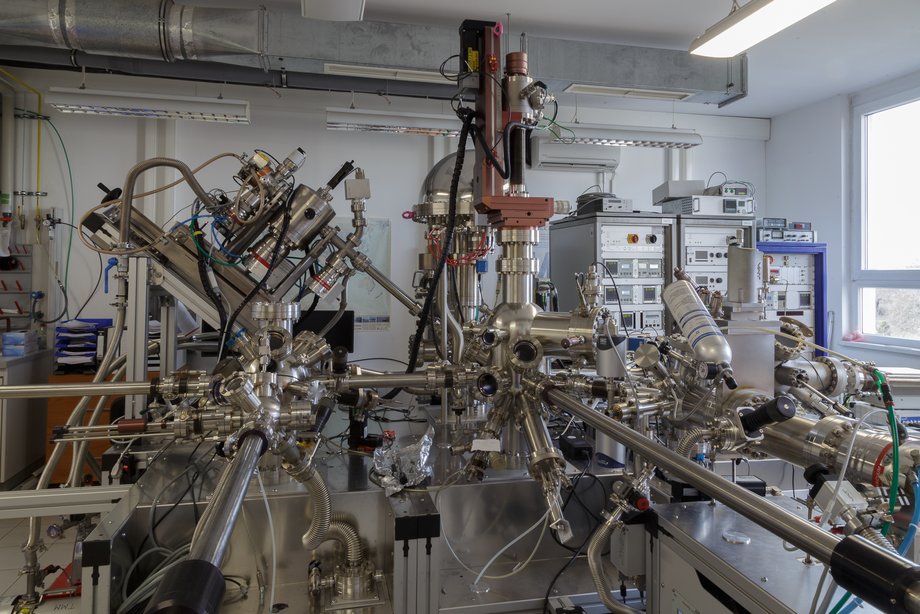

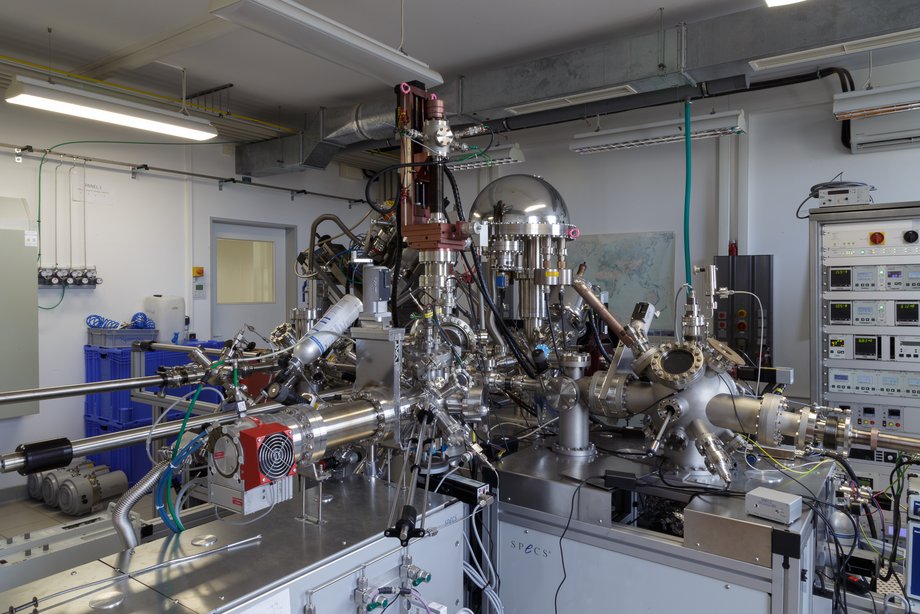

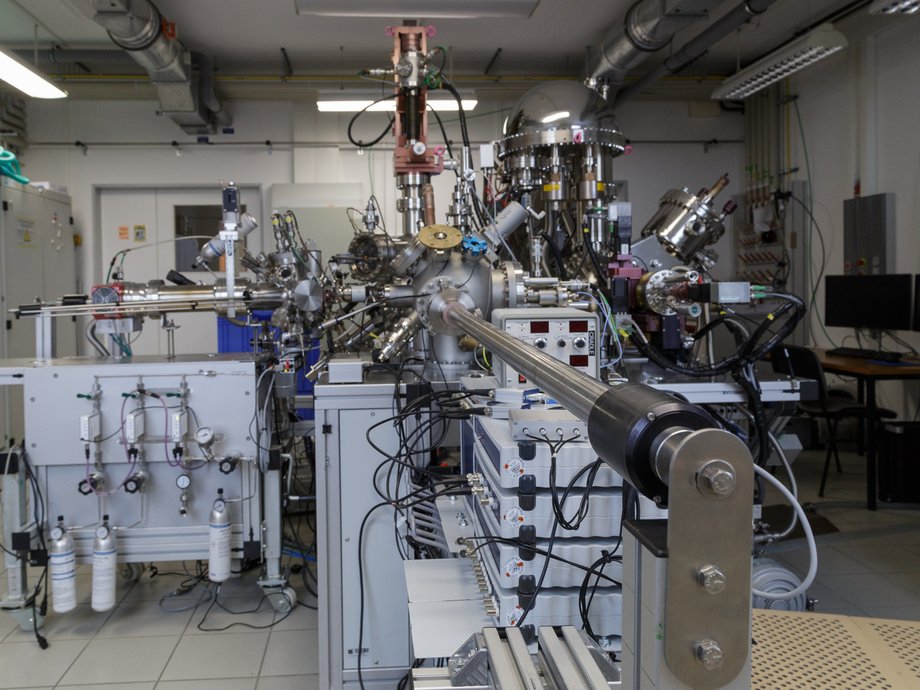

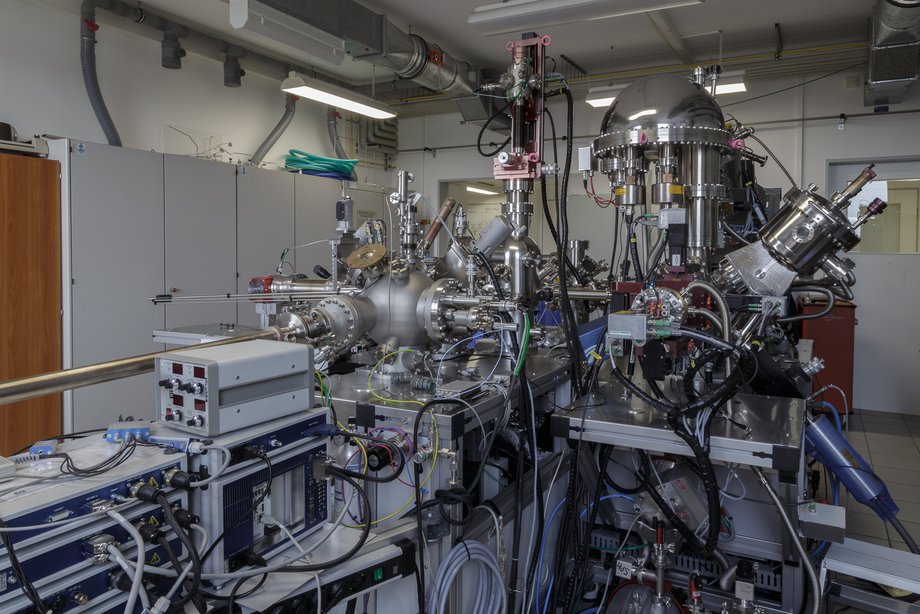

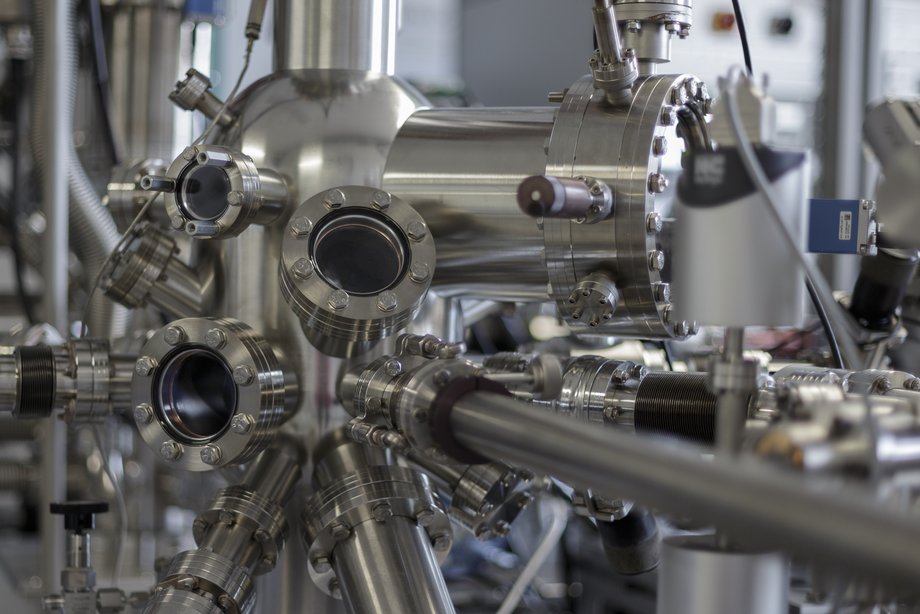

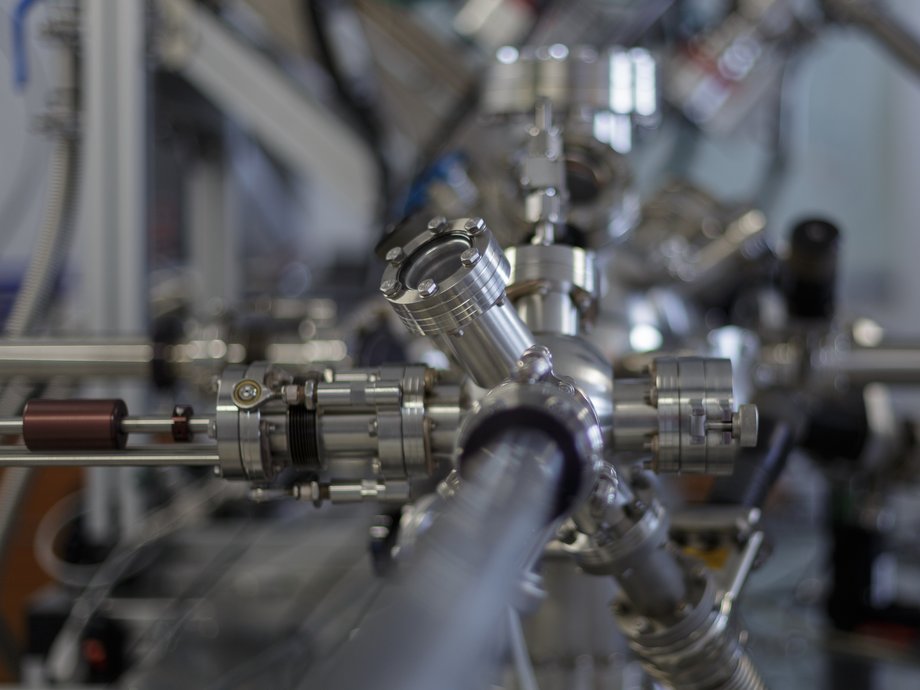

Surface Science Cluster

- Sample preparation (cleaning)

- Preparation chamber and load-lock

- Ion sputtering with reactive (Oxygen) und non-reactive (Argon) gases

- Annealing at elevated temperatures

- E-beam heating up to 1200 °C

- Direct current up to bis 12 A

- Material deposition

- 2 Preparation chambers

- Molecular beam epitaxy

- Sub-monolayer deposition

- Multilayer thin film growth

- E-beam evaporator for metal deposition

- Chemical vapor deposition (CVD) at high pressure

- Temperature: liquid Nitrogen up to high temperature

- in-situ transfer to the analysis chambers

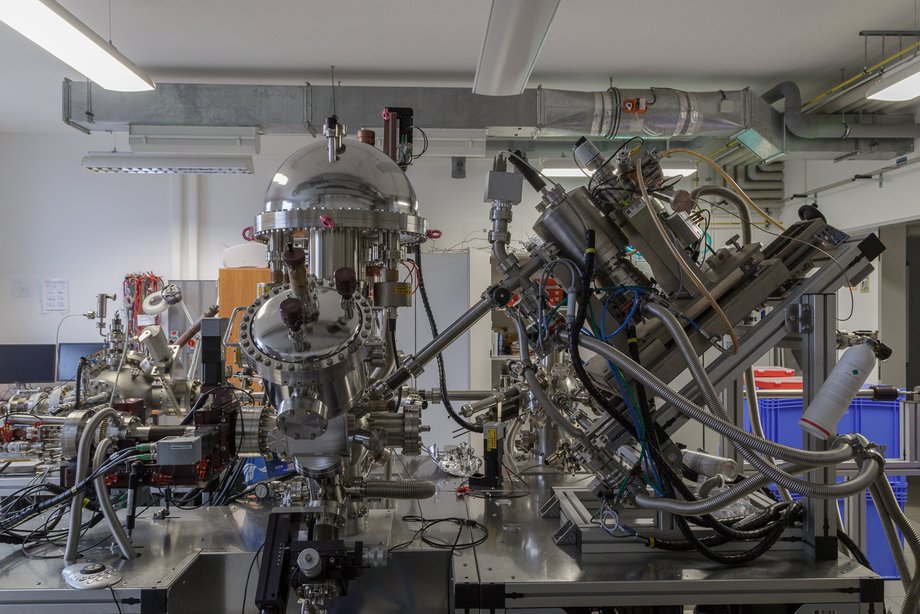

- Photoelectron spectroscopy

- Electron analyzer system

- Phoibos 150 SAL (scanning lens)

- 2D-CCD-Detector

- XR50 dual anode X-ray source

- X-ray photoelectron spectroscopy (XPS)

- Monochromatized Al Kα (1486,7 eV) and Ag Lα (2986,4 eV)

- UVS 300

- Ultraviolet photoelectron spectroscopy (UPS)

- Angle-resolved photoemission spectroscopy (ARPES)

- Monochromatized He I (21.2 eV) and He II (40.8 eV)

- 5-axis manipulator

- ±70° polar angle rotation

- Cooling via liquid Nitrogen or liquid Helium

- E-beam annealing

- Electron analyzer system

- Low-Energy ElectronDiffraction (LEED)

ErLEED 150 Optics

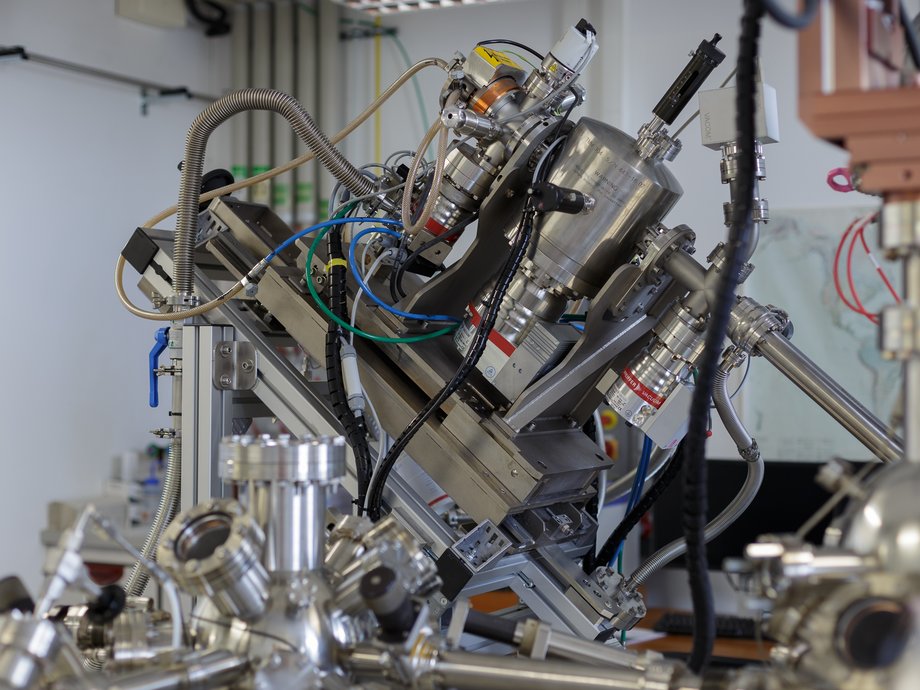

- Scanning Probe Microscopy (SPM)

- SPM: Aarhus 150 HT

- Scanning Tunneling Microscopy (STM)

- Measuring modes:constant height (CH), constant current (CC)

- Atomic Force Microscopy (AFM)

- Non-contact (nc)

- Kelvin Probe Force Microscopy (KPFM)

- Measuring modes: contant height (CH), constant force (CF)

- Spectroscopy: I(V), I(z), dI/dV, Δf(V), Δf(z)

- Temperature: 150 up to 1000 K