Additive manufacturing

Additive manufacturing

Additive manufacturing is an innovative manufacturing method in which three-dimensional objects are built up layer by layer. Unlike conventional processes, in which material is removed from a blank, additive manufacturing adds material step by step to create the desired end product. At chesco, it is used in particular in prototype construction and for components with a high degree of individualization.

A special feature of additive manufacturing processes is that the manufacturing process takes place without tools and without molds directly on the basis of 3D CAD model data. This model is broken down into thin layers and then successively built up. Suitable materials include plastics as well as metallic or ceramic materials. The layer-by-layer construction method makes it possible to realize complex shapes and structures that could not be achieved using conventional methods. With the design freedom gained, components can be created more efficiently, lighter and functionally optimized without having to take into account the limitations of conventional manufacturing processes.

Binder jetting

- Manufacturer: Desktop Metal

- Installation space: 200 x 100 x 40 mm³

- Number of print heads: 2 pieces

- Number of nozzles: 4096 pieces

- Maximum build-up rate: 1,200 cm³/h

- Resolution: 1,200 dpi

- Minimum layer thickness: 30 µm

- Maximum layer thickness: 200 µm

- Maximum deviation: +/- 0.3 mm

- Atmosphere: Nitrogen

- Material restriction: none (free use of material possible)

- Processable materials: steels, copper, silver, gold, cobalt

- Peripherals: Furnace, drying oven, depowdering station, blending station

- Manufacturer: Desktop Metal

- Installation space: 350 x 220 x 100 mm³

- Number of nozzles: 70,000 pieces

- Maximum build-up rate: 800 cm³/h

- Resolution; 1,600 dpi

- Minimum layer thickness: 50 µm

- Maximum layer thickness: 100 µm

- Maximum deviation: +/- 0.3 mm

- Material restriction: Desktop Metal Powder

- Processable materials: 17-4 PH, 304L, 316L, CoCrMo, Inconel 625, Inconel 718

- Peripherals: Furnance, drying oven, depowdering station, blending station

- Manufacturer: Voxeljet

- installation space: 1.000 x 600 x 500 mm³

- resolution: 300 dpi

- Layer thickness: 100 µm

- Process speed: 65 s/layer

- Processable materials: ceramics

- Peripherals: Powder preparation, finishing station, heating cabinet

- Manufacturer: Voxeljet

- Product: VX 1000 CDB

- Installation space: 1,000 x 600 x 500 mm³

- Resolution: 300 dpi

- Layer thickness: 100 µm

- Process speed: 65 s/layer

- Processable materials: ceramics

- Peripherals: Powder preparation, finishing station, heating cabinet

Laser Powder Bed Fusion

- Process: LPBF

- Manufacturer: EOS

- Product: M 400

- Maximum installation space: 400 x 400 x 350 mm³

- Laser power: 1,000 W (green)

- Minimum layer thickness: 40 µm

- Scanning speed: 6 m/s

- Atmosphere: nitrogen, argon

- Material restriction: none (free use of materials possible)

- Processable materials: copper, copper alloys

- Periphery: Screening station

- Manufacturer: EOS

- Product: M 290

- Maximum installation space: 250 x 250 x 275 mm³

- Laser power: 400 W (red)

- Minimum layer thickness: 20 µm

- Scanning speed: 6 m/s

- Atmosphere: nitrogen, argon

- Material restriction: none (free use of materials possible)

- Materials that can be processed: steel, nickel-based, titanium, aluminum alloys

- Periphery: Screening station

Fused Filament Fabrication

Desktop Metal Studio System

- Manufacturer: Desktop Metal

- Product: Studio System

- Installation space: 300 x 200 x 200 mm³

- Number of print heads: 2 pieces

- Maximum component weight: 6 kg

- Minimum layer thickness: 50 µm

- Maximum layer thickness: 300 µm

- Material restriction: Desktop Metal Rods

- Materials that can be processed: 17-4 PH, 316L, Inconel 625, 4140, A2 tool steel, copper, D2 tool steel, H13, Ti64

- Peripherals: Furnance, drying oven, depowder station, blender station

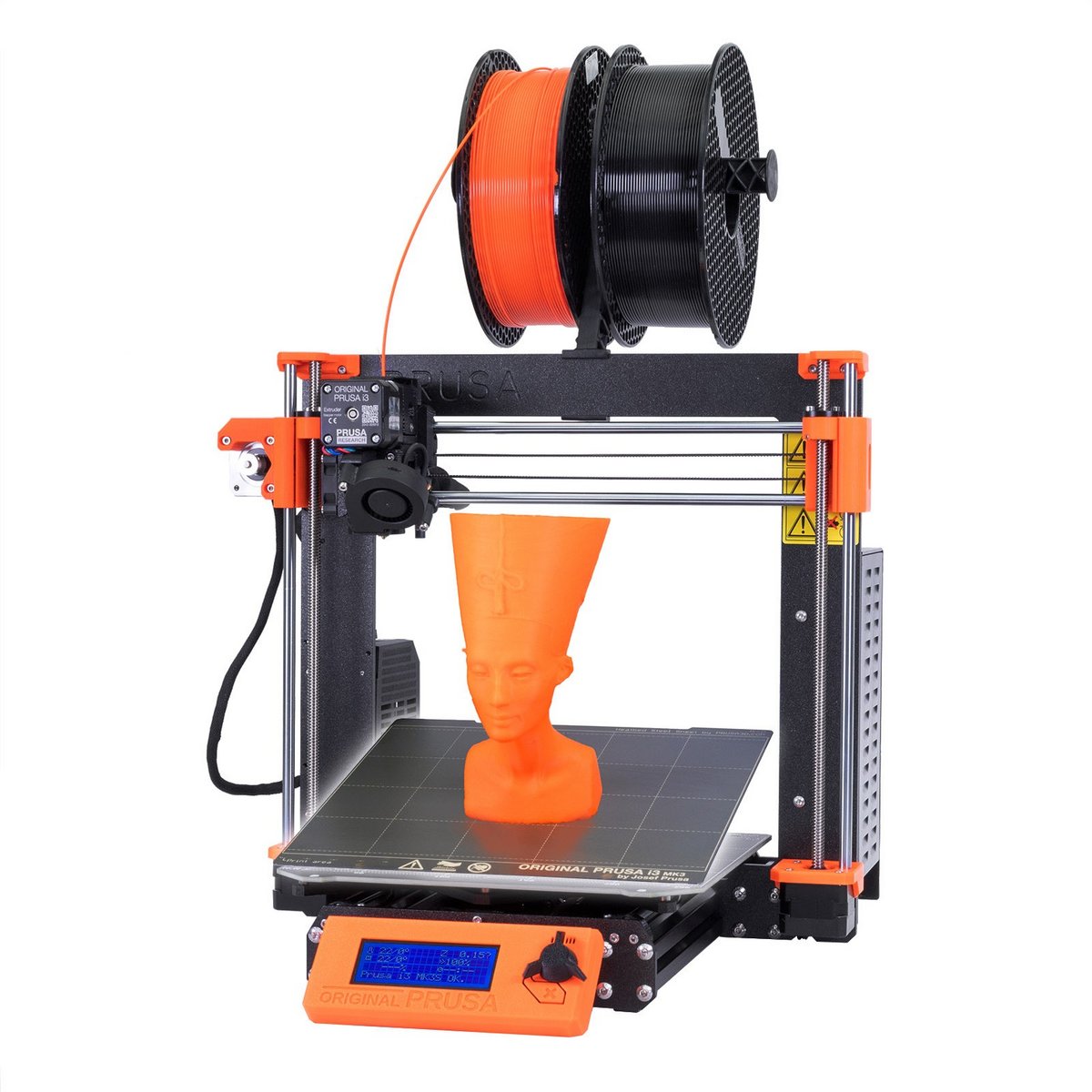

Prusa i3 MK3S+

- Manufacturer: Prusa

- Product: i3 MK3S+

- Maximum component size: 250 x 210 x 210 mm

- Layer height: 0.05 - 0.35 mm

- Maximum traversing speed: 200 mm/s

- Maximum nozzle temperature: 300 °C

- Maximum heating bed temperature: 120 °C

- Materials that can be processed: Thermoplastic

- Manufacturer: AIM3D

- Product: ExAM 255

- Maximum part size: 255 x 255 x 255 mm³

- Maximum part weight: 65 kg

- Number of extruders: 2 pieces

- Minimum layer thickness: 28 µm

- Maximum traversing speed in the application: 200 m/s

Stereolithography

- Manufacturer: Formlabs

- Product: Form 3L

- Resolution: 25 µm

- Maximum part size: 335 x 200 x 300 mm³

- Layer thickness: 25 - 300 µm

- Processable materials: Synthetic resin

Metal injection molding

- Manufacturer: Arburg

- Product: Allrounder 470 S 1100-70/70

- Design: 2 component design

- Column distance: 470 x 470 mm²

- Maximum clamping force: 1,100 kN

- Cycle time: 45 s

- Stroke volume injection unit: 20 cm³

- Stroke volume plasticizing cylinder: 32 cm³

- Maximum injection pressure: 2000 bar

- Functions: Heating, evacuation, stamping, venting, cooling

- Materials that can be used: steel, aluminum, stainless steel