Inspection and analysis

Inspection and analysis

Inspection and analysis are essential steps in the quality control and quality assurance of products and materials. These procedures are used to ensure that manufactured workpieces or semi-finished products meet the requirements in terms of shape and their mechanical properties.

Inspection involves the visual examination of products to ensure that they are externally free of defects, flaws or damage and that they conform to the geometric specification. The goal is to detect deviations from the expected shape and adjust parameters of upstream manufacturing processes.

The analysis includes detailed tests to verify the material, structural or functional properties of components. Technological instruments and methods such as videoscopy, X-ray examinations and metallogical examinations are used here. Various analysis methods make it possible to uncover problems and identify the causes of deviations from simulated results within the manufacturing chain.

Tactile and optical inspection

Hexagon Metrology Leitz PMM-C 16.12.10

- Manufacturer: Hexagon Metrology

- Product: Leitz PMM-C 16.12.10

- Measuring technique: tactile / optical

- Maximum part size: 1,600 x 1,200 x 1,000 mm³

- Maximum part weight: 750 kg

- Component support: rotary table

- Test forms: Form inspection, coordinate measurement, gear measurement, run, total run

- Data rate: 1000 points/s

- Probing deviation MPEE according to DIN EN ISO 10360: 0.8 + L/650

- Repeat span according to DIN EN ISO 10360: 0.4 µm

- Single probe Shape deviation according to DIN EN ISO 10360: 0.4 µm

- Probes: Senmation, Probe X5, HP-O

- Environment: Air-conditioned measuring room

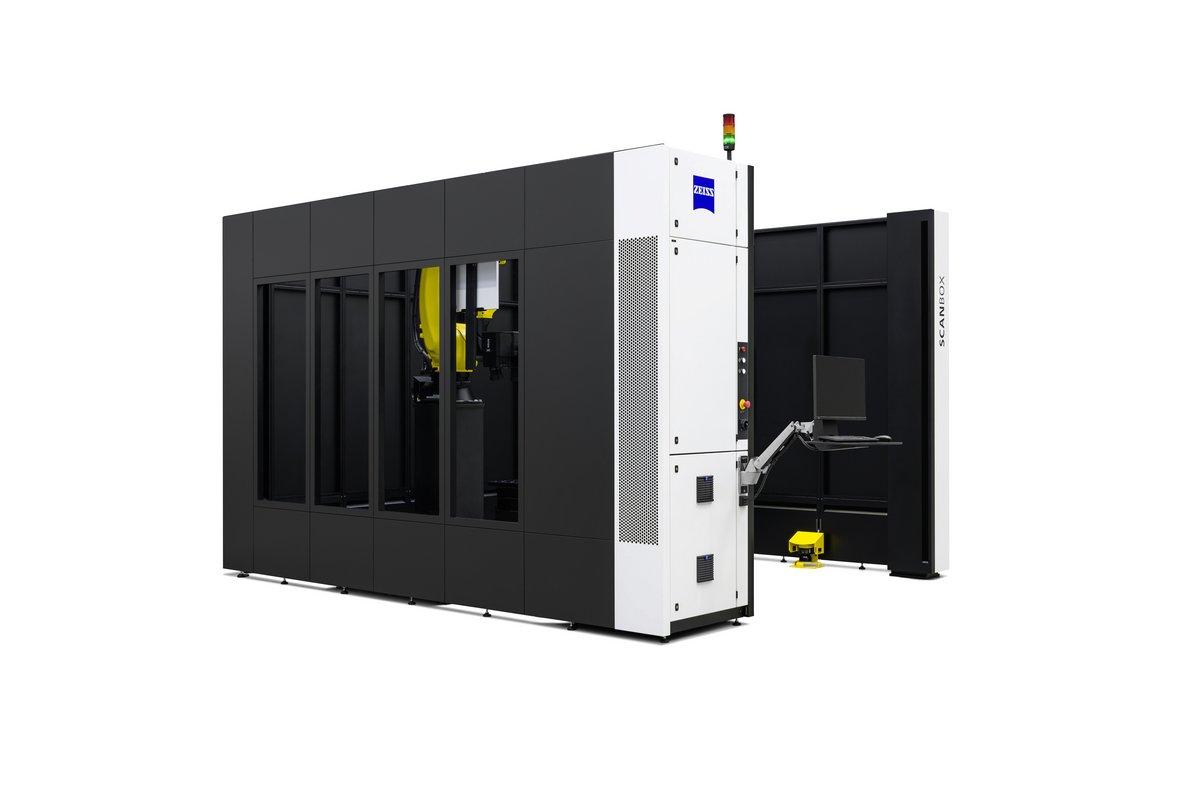

- Manufacturer: Zeiss GOM Metrology

- Product: ScanBox 5120 with ATOS 5 Airfoil

- Maximum part diameter: 2.000 mm

- Maximum part size: 2.000 mm

- Maximum part weight: 2.000 kg

- Scan fixture: 6-axis articulated arm robot

- Component support: rotary table

- Measuring head - number of cameras: 2 pcs.

- Measuring head - Camera resolution: 12 MP

- measuring head - measuring field 1: 400 (+/-30) x 300 (+/-30) mm²

- measuring head - measuring field 1: 150 (+/-30) x 120 (+/-30) mm²

- Photogrammetry - resolution camera: 45 MP

- photogrammetry - field of view: 500 (+/-30) x 350 (+/-30) mm²

- Maximum axis speed: 50 m/min

- Position tolerance: 0.015 mm

- Maximum laser power: 6,000 W disk laser

- Cutting gases: nitrogen, oxygen

- Welding gases: argon, nitrogen, carbon dioxide

- Control: Siemens 840D

Landgraf Flowmeter

- Manufacturer: Landgraf

- Product: Flowmeter

- Functions: Bulk density measurement, flow rate measurement

- Particle size and shape analyzer

- Manufacturer: Microtrac Retsch

- Product: Camsizer X2

- Resolution: 0.8 µm/pixel

- Maximum sample quantity: 500 g

- Particle size range: 0.8 µm - 8 mm

- Functions: Particle size measurement, particle shape analysis

- Endoscope

- Manufacturer: Baker Hughes

- Product: XLDEB4020 / XLDEB6120

- Probe length: 2 m

- Endoscope probe 1 - diameter: 4 mm

- Endoscope probe 2 - diameter: 6.1 mm

- Number of axes: 7 pieces

- Measuring technique: tactile / scan

- Maximum component diameter: 2500 mm

- Maximum part height: 2500 mm

- Measuring arm deviation E(Uni): 0,029 mm

- Measuring arm deviation P(Size): 0.011 mm

- Measuring arm deviation L(Dia): 0.044 mm

- Measuring arm deviation P(Shape): 0.023 mm

- Measuring arm deviation SSA: 0.043 mm

- Scanning point acquisition rate: 1,200,000 points/s

Scanning accuracy: 0.016 mm

Baker Hughes XLDEB4020 / XLDEB6120

- Manufacturer: Baker Hughes

- Product: XLDEB4020 / XLDEB6120

- Probe length: 2 m

- Endoscope probe 1 - diameter: 4 mm

- Endoscope probe 2 - diameter: 6.1 mm

- Manufacturer: Microtrac Retsch

- Product: Camsizer X2

- Resolution: 0.8 µm/pixel

- Maximum sample quantity: 500 g

- Particle size range: 0.8 µm - 8 mm

- Functions: Particle size measurement, particle shape analysis

Keyence VHX-700

- 3D Microscope

- Manufacturer: Keyence

- Product: VHX-700

- Image size: 50.000 x 50.000 Pixel

- travel range: 100 x 100 x 80 mm³

- Magnification - objective 1: 0x - 50x

- magnification - objective 2: 50x - 500x

- Magnification - Lens 3: 500x - 5000x

- Functions: 3D profile measurement, 3D roughness measurement, transmitted light microscopy, mixed illumination, bright field microscopy, dark field microscopy, panoramic image, area analysis

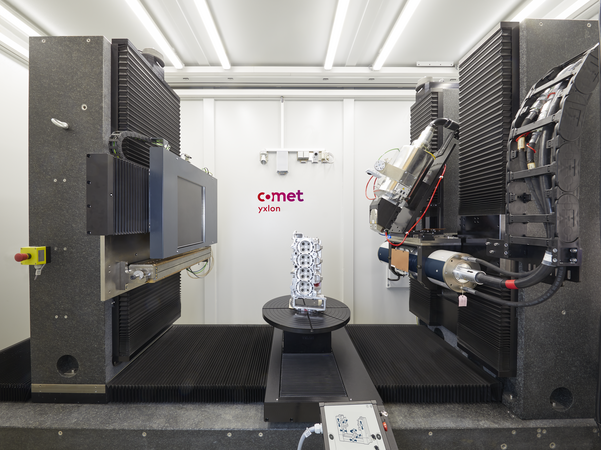

X-ray computed tomography

- Manufacturer: Yxlon

- Product: FF85 CT X-Ray

- Maximum part height: 950 mm

- Maximum part diameter: 1000 mm

- Number of manipulation axes: 7 axes

- Maximum test part mass: 350 kg

- X-ray voltage: 20 - 450 kV mini focus tube

- flat panel detector - active area: 432 x 432 mm²

- flat panel detector - pixel pitch: 150 µm

- flat-panel detector - number of pixels: 2,880 x 2,880

- line detector - active length: 780 mm

- line detector - pixel count: 3072 µm

- Line detector - pixel pitch: 254 µm

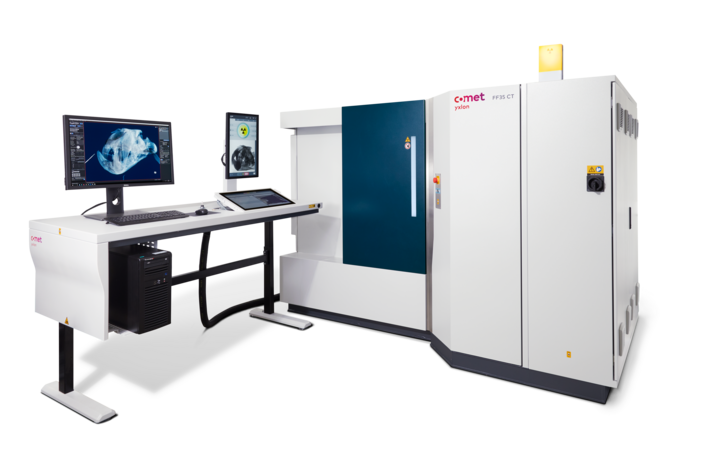

- Manufacturer: Yxlon

- Product: FF35 CT X-Ray

- Maximum part height: 600 mm

- Maximum part diameter: 500 mm

- Maximum test part mass: 25 kg

- Number of X-Ray tubes: 2 pieces

- Number of manipulation axes: 6 axes

- X-ray voltage 1: 20 - 225 kV microfocus tube

- X-ray voltage 2: 20 - 190 kV nanofocus tube

- Product: Multivibrator MV 25/3

- Functions: Fine grinding, smoothing, deburring, polishing

- Maximum component diameter: 700 mm

- Maximum component height: 650 mm

- Maximum speed: 3.000 rpm

- Workpiece clamping: magnetic plate, threaded rod

Roughness measurement

- Manufacturer: Mahr

- Product: MarSurf M310

- Maximum measuring range: 350 µm

- Resolution: 8 nm