Heat treatment and sintering

Heat treatment and sintering

Heat treatment

refers to processes in which workpieces are specifically heated to precise temperatures and then cooled in a controlled manner in order to optimize their mechanical properties. Various effects can be achieved with the aid of these processes, such as an increase in material hardness, strength, toughness or corrosion resistance. The material to be processed passes through various temperature stages over defined periods of time and is cooled in different media at varying rates depending on the material type and process. This ranges from slow furnace cooling to rapid quenching to adjust specific mechanical properties.

Sintering

represents a method of creating solids in which a solid mass of a wide variety of powder or feedstock mixtures are compressed by heating and under high pressure. This produces "end-solid" components from fragile green bodies at temperatures just below their melting point. During sintering, the particles fuse at the contact points, resulting in a compacted and stable structure. This process opens up the possibility of manufacturing complex components with targeted properties.

Sintering

- Manufacturer: IBT

- Product: Sintering furnace (special design)

- Power: 240 kW

- Max. Temperature: 1.600 °C

- Atmospheres: Vacuum, nitrogen, argon, hydrogen

- Max. component size: 500 x 500 x 650 mm³

- Number of heating zones: 3 pieces

- Temperature homogeneity: +/- 5 K

- Operating pressure: up to 5 x 10^-5 mbar

- Cooling time to < 100°C (full oven): 4 h

- Cooling time to < 100°C (empty furnace): 2 h

- Functions: Debinding, sintering, residual debinding via partial pressure process.

- Manufacturer: IBT

- Product: Sintering furnace (special design)

- Power: 60 kW

- Max. Temperature: 1.600 °C

- Atmospheres: Vacuum, nitrogen, argon, hydrogen

- Max. component size: 220 x 300 x 220 mm³

- Number of heating zones: 2 pieces

- Temperature homogeneity: +/- 5K

- Operating pressure: up to 5 x 10^-5 mbar

- Cooling time to < 100°C (full oven): 4 h

- Cooling time to < 100°C (empty furnace): 2 h

- Functions: Debinding, sintering, residual debinding via partial pressure process.

- Manufacturer: ALD Vacuum Technologies

- Product: MonoTherm HK.446.N.15.gr

- Max. Component size: 400 x 400 x 600 mm³

- Max. component weight: 200 kg

- Maximum temperature: 1.300 °C

- Heating power: 80 kW

- Temperature homogeneity: +/- 10 K

- Quenching gases: argon, nitrogen

- Max. Quenching pressure: 15 bar

- Max. Vacuum: 5 x 10^-5

- Partial pressure range: 1 - 15 mbar

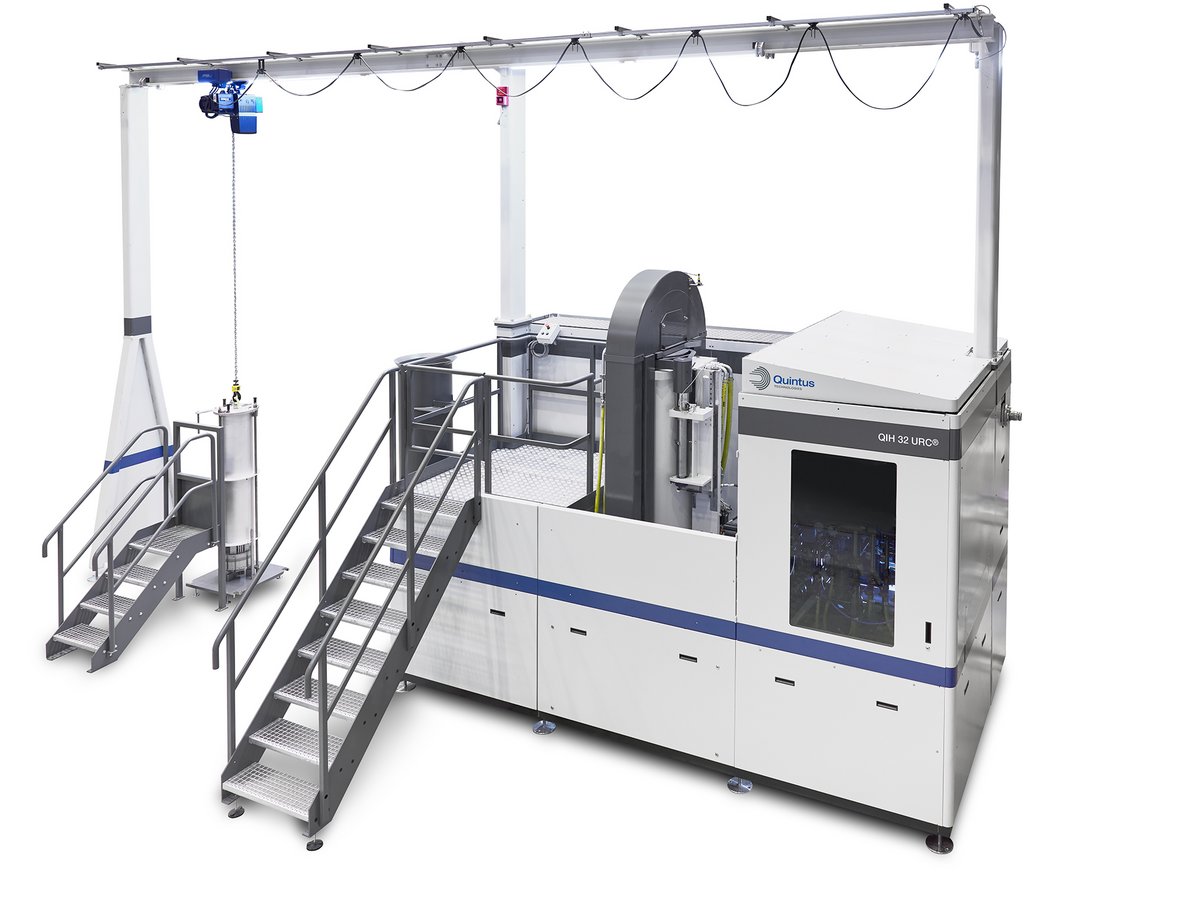

Hot Isostatic Pressing (HIP)

- Manufacturer: Quintus Technologies

- Product: Hot Isostatic Press QIH 32

- Maximum working pressure: 207 MPa

- Boiler volume: 242 dm³

- Maximum component height: 870 mm

- Maximum part diameter: 285 mm

- Maximum part weight: 300 kg

- Maximum temperature deviation: +/- 8°C

- Number of heating zones: 3 pieces

- Heating rate: up to 25 K/min

- Cooling rate: up to 100 K/min

- Maximum temperature: 1,400 °C

- Atmosphere: Argon

Infiltrate

Vacuum infiltration AMS- Anlagenbau

- Manufacturer: AMS-Anlagenbau

- Product: custom made

- Suspension: colloidal silica, isopropanol

- Maximum component size: 1000 x 600 x 500 mm³

- Maximum vacuum: 0,5 mbar