Fuel cell

The core of the energy conversion process lies in the fuel cell cluster.

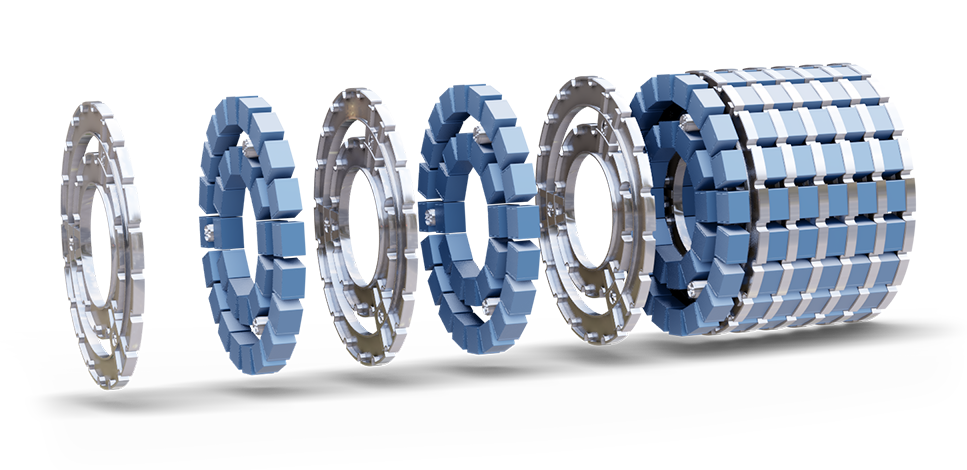

It comprises two layers of concentric cylinders, which consist of symmetrically stacked ceramic fuel cells.

Each of these cells has two sides, separated by a ceramic membrane: on one side, the synthesis gas enters from the reformer; on the other side, the heated fresh air enters from the heat exchanger. The ceramic material has the inherent property of conducting oxygen ions at the prevailing process temperature. Thus, a transfer of oxygen ions is facilitated from the fresh air side to the synthesis gas side of the fuel cell, through the ceramic membrane. The release of ions from the fresh air side to the synthesis gas side therefore generates an electrical voltage, which is used for a current flow by introducing a connecting conductor. As the fuel cell is incomplete, it gives off heat in this process. The high-temperature fuel cell generates heat input into the gas turbine process and its function can be understood in the same way as that of a combustion chamber.

Solid-electrolyte fuel cells are a low-CO2, efficient technology for electrical energy generation. The solid-electrolyte fuel cell consists of three elements: a gas-tight, insulating electrolyte that conducts oxygen ions, as well as electrodes, a cathode and an anode fitted on two opposite sides of the electrolyte. When the air is fed into the porous cathode, oxygen ions are isolated and deposited on the surface of the electrolyte, and electrons are released. On the other side of the electrolyte, the anode side, to which combustion gas such as hydrogen and/or methane flows, the oxygen concentration is significantly lower. This gives rise to a different electrical potential on both sides, which produces a measurable voltage. This potential is balanced out, as oxygen ions move from cathode to anode through the solid electrolyte grid. Under these conditions, the electrons released from the cathode can be used to power a suspended load. On the anode, the electrodes then react with the oxygen ions from the electrolyte and the hydrogen contained in the combustion gas to form water vapour. This process takes place at temperatures between 700°C and 1000°C, at which the oxygen ion conductivity of the electrolyte is high enough and base metals can be used as catalysts.

The cells are stacked, in order to increase the power gained from a fuel cell. To do this, an electrical but gas-tight connection must be made between the cell electrodes. Interconnectors are used for this, which are electrically conductive but gas-tight and non-conductive of ions. These are additionally provided with glass seals. Fuel cell stacks can be constructed using these components. Solid electrolyte fuel cell stacks of type MK35x from Fraunhofer IKTS are used in the fuel cell cluster of the T-cell.