Aerodynamics

Boundary layer flows

Turbulent Boundary Layer Flow Control Using Micro-Blowing

Large organized vortex clusters that dominate the nature of turbulent flow play an important role in the turbulence production process of a boundary layer and can cause extreme fluctuations. They affect the global transport of mass, heat and momentum. Control over these structures and their dynamics is very important for many technical applications such as reducing drag of naval transport and airplanes as well as for reducing the noise and low frequency vibration of wind turbine blades. Drag reduction schemes are to be considered as partial/potential solutions to some of the escalating energy problems worldwide. Hence, better understanding of physics of the turbulent flow structure, especially during their formation is required.

Uniform micro-blowing technique (MBT) is an effective methodology affecting turbulent boundary layer flows. According to Hwang (2004) using of the micro blowing technique to control the turbulent boundary layer reduces skin friction significantly, e.g. by 60% in the subsonic flow and up to 90 % in the subsonic flow.

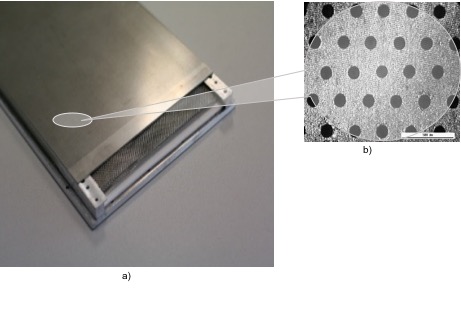

Starting in 2009, an experimental investigation at LAS BTU-CS has been carried out to understand the control mechanism of turbulent boundary layer by using micro-blowing through a uniformly perforated surface. Therefore, the devices were designed, manufactured and equipped with autonomous pressure chambers, including instruments for pressure equalization as well as adjustable micro-permeable plates (Fig. 1 and 2). Furthermore, experimental facilities including an air supply system to organize the micro-blowing and a precision mass-flow meter to measure the flow rate were developed and integrated in the experimental set up, see Figure 8. This set up was utilized to investigate the turbulent boundary layer along a flat plate concerning its controllability by means of a uniform and continuous micro-blowing in a turbulent flow under zero pressure gradient. The investigation encloses the flow behaviour in a viscous sublayer above a permeable wall without and with micro-blowing. The influence of the blowing rate and the temperature of the blowing air on the boundary layer parameters was investigated. Flow visualisation and qualitative analysis of the effect of the micro-blowing flow temperature on the temperature field of permeable wall surface under various flow conditions was carried out as well.

The investigation was performed in a closed-return subsonic wind tunnel of LAS BTU for a Reynolds number range of 1×104 ≤ Rex ≤ 9×105 and for a blowing ratio of 0 < F < 0.0173, where Rex is based on the free stream velocity (Uµ), the streamwise distance (x) and fluid kinematic viscosity (n).

Flow velocity distribution in the wall proximity as well as the effect of the blowing rate and the temperature of the blowing air on the parameters of the boundary layer has been carried out utilizing the non-invasive Laser Doppler Anemometer (LDA). In order to examine the temperature field of permeable wall surface and its variation, a thermographic system based on an Infrared camera was used.

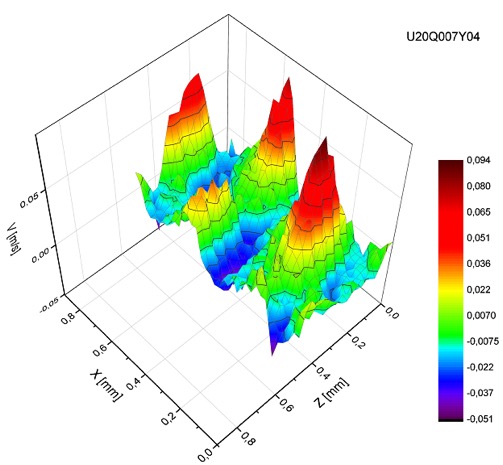

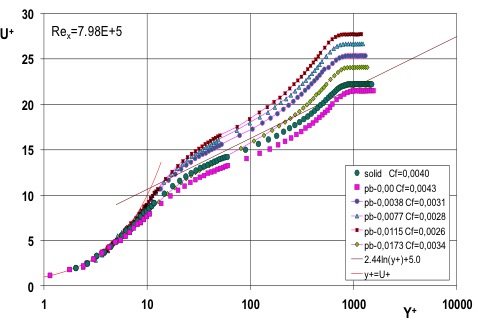

The measured flow velocity distribution u(x,z) and particularly u(x,z) showed that the micro-blowing through the uniformly distributed micro-holes of the permeable wall can be described as an "ensemble" of single jets. For subsonic flow, this kind of blowing description may be accepted roughly as a uniform micro-blowing (Fig. 3). Micro-blowing of air in the turbulent boundary layer shifts a logarithmic part of the streamwise mean velocity profiles scaled by local wall units depending on the blowing ratio, see Fig.4 (Motuz (2004)).

Selected samples of test results showed that uniform micro-blowing reduces the turbulent wall skin friction by up to 50 % in comparison to the solid wall for the same Reynolds numbers 1×104 ≤ Rex ≤ 1×106. It was observed that the skin friction and wall shear stress of a permeable wall with micro-blowing also depends on the blowing rate (F) and the wall skin reduction takes place only for a certain working range of the blowing ratio F.

As a result of the interaction between the micro-blowing and the main flow, an overlap layer was being formed, which blocks the energy exchange between the turbulent structures of external part of the boundary layer and the small turbulent structures near the permeable wall. This overlap layer arises not immediately at the beginning of the blowing area, but rather at a distance that depends on the blowing ratio.

Bibliography

- Hwang, D. P. (2004). Review of research into the concept of the microblowing technique for turbulent skin friction reduction Progress in Aerospace Sciences 40, 559-575

- Motuz, V., 2014, Gleichmäßiges Mikro-Ausblasen zur Beeinflussung einer turbulenten Grenzschicht. Doctoral thesis, department of Aerodynamics and Fluid Mechanics, BTU Cottbus-Senftenberg.